Digital Metal Adds Pure Copper to Metal Binder Jetting System

Thermal and conductive properties of pure copper open new 3D printing possibilities within many industries.

Share

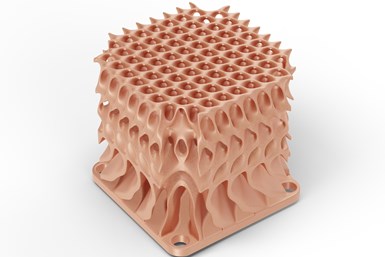

Pure copper’s thermal and electrical conductivity properties make it well suited for a wide range of industrial AM applications.

Digital Metal, a provider of high-precision metal binder jetting systems for industrial use, has added pure copper (DM Cu) to its material offering. Pure copper’s excellent thermal and electrical conductivity properties make it well suited for a wide range of applications.

A key benefit is that printing with 99.9% pure copper brings out the best of the material, compared to copper alloys commonly used in laser-based systems, the company says.

Good conductivity, or heat transfer, is a requirement in electronics, heat exchangers, heat sinks and engine parts. 3D printing of components in copper offers more design freedom, enabling design for optimal functionality with very few restrictions. In addition, copper is known for its antibacterial properties.

The addition is timely as the demand for copper applications has accelerated in fast growth areas such as e-mobility and heat conductivity Digital Metal is one of the world’s first companies to commercialize state-of-the-art 3D metal printers for the production of small components with advanced geometries. Digital Metal’s binder jetting technology enables the production of complex objects with superior surface finish, which is not possible with competing technologies.

Related Content

-

Multimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

-

Desktop Metal Expands Metal Binder Jet Lineup With Shop System+, Shop System Pro

A turnkey metal 3D printing system, the Shop System is an affordable, closed material printer that delivers reliable results with optimized powders, proven parameters and Live Sinter simulation and scanning software.

-

Video: Multimodal Powders for Metal 3D Printing

Rather than uniform particle diameters, multimodal powders combine particles of different sizes. In this video, how and why Uniformity Labs produces multimodal metal powders for additive manufacturing.