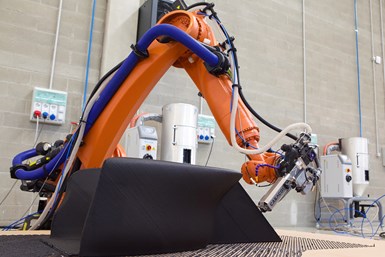

Caracol Develops Smart 3D Printing System for Large-Scale Components

The monitoring and automation system is designed to enable enhanced productivity.

Caracol worked with the MADE Competence Center and Politecnico di Milano to develop the RAMICoS - Intelligent Control System for robotic large-scale additive manufacturing systems (LFAM). The project was financed by the Italian Ministry of Economic Development.

Through this collaborative project, the company aimed to identify common problems occurring during the printing process of Robotic LFAM Systems, defining and characterizing the related defects generated that affect the deposition of the extruded material. It also looked to identify the types of sensors and their correct placement, to gather the appropriate data from process monitoring and control. The team carried out testing and trial sessions to assess the effectiveness of the proposed sensors’ integration. It also ran a trial session to mitigate the risks related to material quality issues, regarding fiber-reinforced polymers and new materials. Further, the company aimed to identify a data collection and analysis system, to detect and track anomalies while providing insights to support decision-making.

For the project’s execution phase, Caracol’s LFAM system Heron AM was equipped with about 10 sensors to track different parameters, including the system and its components’ electricity consumption, the working environment’s temperature and humidity, the extrusion temperature, possible shocks and vibrations to the extruder, the energy consumed by the extruder’s screw motor, and more. By registering all these signals and collecting data, a digital twin of the printed component was generated, enabling the identification of the areas affected by problems with material deposition. Moreover, Caracol developed machine-learning algorithms for automatic defect identification and alarm generation.

The use of such tools can positively impact manufacturing processes and companies in several ways. First of all by facilitating the work of operators as decision-making support, it helps quality and maintenance departments by quickly identifying the root cause of problems, and it helps forecast the use of resources for production such as energy consumption by operational managers.

Bringing this project to completion has opened a phase of further developments for Caracol. The company wants to implement these smart 3D printing solutions to ensure clients can benefit from being promptly notified of any occurring printing issues, and put into place automated corrective actions. The ultimate objective for Caracol is always ensuring the best quality of the printed components while minimizing costs and maximizing process efficiency.

- Listen to this episode of AM Radio to hear AM editors discuss how additive wins on cost, plus process monitoring and more from RAPID + TCT 2023. At the 1:28-minute mark, the team discusses Caracol’s application of robots to do deposition 3D printing in a large format, make big parts, and the demo they were showing which had to do with making new wind turbine blades out of old wind turbine blades.

- Check out this LinkedIn post to see Pete Zelinski’s post about two end-use parts made (or being made) through large-format robotic 3D printing by Caracol AM.

Related Content

-

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Savage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.