ALM’s Polypropylene Powder Offers Higher Elongation at Break

PP 400 polypropylene powder for selective laser sintering provides better impact resistance for use in dynamic environments.

Share

Read Next

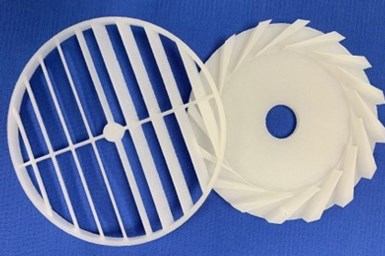

ALM’s PP 400 polypropylene powder provides good impact resistance.

Advanced Laser Materials’ (ALM) PP 400 polypropylene powder is designed for use in selective laser sintering, offering great elasticity and toughness as well as high chemical resistance. It also offers high electrical and fatigue resistance.

The company says the powder offers superior mechanical properties in comparison to other options on the market. In particular, the material offers a 50% elongation of break, providing better impact resistance for use in dynamic environments. Also, no additives (such as absorbers) are required for use, enabling the material to retain the pure chemical component of the polymer as well as its performance. The powder also has high recyclability which enables low cost-per-part manufacturing.

Additional benefits include strong chemical resistance against acids, bases, salts and more; enhanced processing stability; and excellent performance in objects requiring living hinges. It is well-suited for fluid systems, tanks and containers, piping, interior components on automobiles and anything that comes in contact with corrosive fluids.

PP 400 is available for third-party industrial 3D printers and will soon be available for EOS machines as well. It was developed in partnership with Braskem, a leading producer of polyolefins biopolymers. This is the first commercial product launched under that partnership which began in 2018.

Related Content

-

FDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.