Siemens, Xerox Collaborate at Additive Manufacturing Hub

Partnership includes installation of Xerox ElemX 3D printer at the Siemens Charlotte Advanced Technology Collaboration Hub in Charlotte, North Carolina.

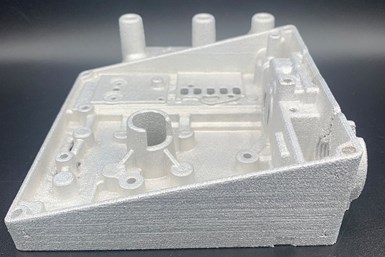

An example part that was 3D printed on the Xerox ElemX machine, powered by the Sinumerik 840D sl control system from Siemens. Photo Credit: Siemens

Siemens is collaborating with Xerox Elem Additive Solutions with an aim to strengthen the metal additive manufacturing (AM) capabilities of both businesses. Siemens has purchased Xerox’s ElemX metal 3D Printer, adding it to its fleet of additive machines inside its Charlotte Advanced Technology Collaboration Hub (CATCH). The CATCH facility focuses on the industrialization of AM, working with machine builders, material suppliers and end customers.

Siemens and Xerox have a mutual interest to explore technical developments in automation, software, materials and processes of the current and future ElemX systems. The ElemX is said to leverage Xerox’s liquid metal AM that uses cost-effective aluminum wire and incorporates the state-of-the-art Siemens Sinumerik 840D sl control platform with its embedded digital twin technology to optimize the printing process.

It is said the ElemX is simpler, safer to use and addresses supply chain resiliency for transportation, aerospace, defense and industrial manufacturing. According to the company, the printer is easily deployed, requiring no special facility modifications for operation. Unlike many metal 3D printing technologies, the ElemX is said to require minimal postprocessing and therefore provides a faster time-to-part.

“We are pleased to join forces with Xerox and drive the industrialization of additive manufacturing through digitalization,” said Tim Bell, head of additive manufacturing, Siemens Industry Inc. “Working together with Xerox, we’re bringing decades of proven Siemens automation experience and technology to additive manufacturing, helping customers mainstream mission-critical production tools for future manufacturing strategies.”

This collaboration provides early access opportunities for Xerox and Siemens to share advancements in digitalization solutions and automation software designed to impact the distributed manufacturing model. Siemens is the latest addition to the Xerox Manufacturing Partner Network (MPN).

“Siemens and Xerox share a similar vision to advance manufacturing through creative and collaborative partnerships that collectively push us forward in the right direction,” said Tali Rosman, VP and GM of Xerox Elem Additive Solutions. “This is another important milestone for our ElemX technology and we look forward to working with an innovative and forward-thinking organization such as Siemens. Together, Siemens and Xerox Elem Additive Solutions will enable our customers to manufacture parts on-demand with confidence and maximize new opportunities to improve supply chain resiliency.”

Related Content

-

Variable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

-

ConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

-

This Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.