Schaeffler Installs Siemens’ AM Network to Facilitate Additive Manufacturing Workflow

The platform is designed to facilitate collaboration, speed time to production and foster greater application of the benefits of AM within its value-chain.

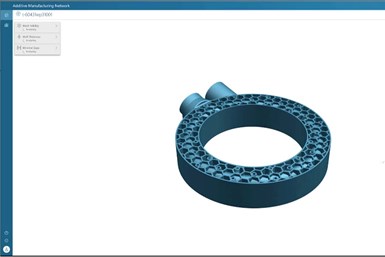

Schaeffler 3D part spray nozzle in AM Network 3D viewer (Image credit: Schaeffler Group)

Schaeffler, a global automotive and industrial supplier, has implemented the Additive Manufacturing (AM) Network fromSiemens Digital Industries Software to connect its community of design engineers with its AM Fab Shop for AM. The AM Network is designed to facilitate collaboration, speed time to production and foster greater application of the benefits of AM within its value-chain.

The platform digitalizes customer AM workflows (order-to-delivery process chain) and partners, and enables them to apply AM on an industrial-grade to scale their business, Siemens says. It is said the AM Network enables customers and partners to build up their own AM ecosystem both internally and with trusted external suppliers/partners. Users are also able to join Siemens’ existing ecosystem that it has established on its AM Network platform.

With demand for AM parts growing exponentially among its R&D designers and engineers, Schaeffler has adopted the AM Network as the single platform for all engineering/technical collaboration throughout its entire AM order-to-delivery process.

This cloud-native platform enables companies to take advantage of AM benefits more quickly, efficiently and at greater rate of scale by digitalizing and streamlining its AM workflows, the company says. R&D designers and engineers are guided through the AM part qualification process, as defined by the AM Fab Shop, while shopfloor operations and machine utilization have been streamlined to increase efficiency.

The company says time and effort are saved with increased throughput, while fostering a wider understanding of the benefits of additive, better formalization of best practices and, ultimately, more efficient execution and more timely delivery of the successfully 3D printed parts.

“Siemens’ Additive Manufacturing Network platform was selected not only to assist orchestrating the end-to-end order-to-delivery process for industrial additive manufacturing but was perceived as a long-term partner to grow with and to explore further opportunities to create a fully digitized end-to-end AM workflow and value chain,” says Carsten Merklein, Schaeffler vice president of advanced manufacturing technologies.

Related Content

-

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

-

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.