Researchers Develop Method for Creating Customized 3D Printed Metals With Contrasting Properties

Researchers were able to use 3D printing techniques and tweak printing parameters to produce a 3D printed metal with different microstructures that create stronger and weaker regions in the exact locations in the metal that they wanted.

Share

Read Next

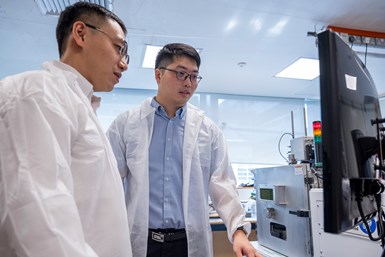

Dr. Gao Shubo (left), a research fellow from NTU Singapore, and Dr. Li Zhi, a scientist from Singapore’s Agency for Science, Technology and Research, used the laser powder bed fusion machine (right) to 3D print the parts in their experiments. Photo Credit: NTU Singapore

Scientists have developed a method that can make customized 3D-printed metal parts containing different properties – such as having some regions of the metal stronger than others. The new technique from the researchers – led by Nanyang Technological University, Singapore (NTU Singapore) and the University of Cambridge — uses 3D printing steps.

Unlike traditional metal manufacturing processes, this technique does not require additional raw materials, mechanical treatment or drastic machining processes to achieve a similar effect (such as coating the metal with a different material), thereby potentially helping to reduce manufacturing costs.

In addition to designing a 3D printed metal part with different strength levels, the process should theoretically also enable manufacturers to design a part with other features, such as differing levels of electrical conductivity or corrosion resistance in the same metal.

The researchers were led by Professor Gao Huajian, a university professor at NTU Singapore in the School of Mechanical and Aerospace Engineering (MAE), and Assistant Professor Matteo Seita from the University of Cambridge, who was on the NTU faculty when the study was done. They took inspiration from “heating and beating” methods similar to millennia-old steps involved in blacksmithing to develop the new process.

This led them to combine materials science and mechanical engineering principles, and apply 3D printing techniques usually used to remove and prevent defects in printed metals to alter microscopic structures in the metals to change their properties.

The method also enables manufacturers to decide the type of internal microstructure they want — and thus the type of property — and where precisely it can be formed in the metal. This improves on traditional means which do not have such fine control.

“Our method opens the way for designing high-performance metal parts with microstructures that can be fine-tuned to adjust the parts’ mechanical and functional properties, even at specific points, and allowing them to be shaped in complex ways with 3D printing,” Huajian says.

The new process is described in a paper published in “Nature Communications” in October 2023. It exemplifies a key focus of the NTU 2025 strategic plan to create high-impact interdisciplinary research.

The other scientists in the research team are from the Agency for Science, Technology and Research’s (A*STAR) Singapore Institute of Manufacturing Technology; A*STAR’s Institute of High Performance Computing; Switzerland’s Paul Scherrer Institute; the VTT Technical Research Centre of Finland; and the Australian Nuclear Science and Technology Organisation.

Materials Science Meets 3D Printing

The new 3D printing method arose from an interdisciplinary solution developed by research fellow Dr. Gao Shubo at NTU’s MAE during his doctoral studies at the university. Shubo, the first author of the research paper detailing the new method, had tried to find a way to alter microstructures in 3D printed metals and change their properties without resorting to “beating” the metal.

For traditionally made metals, the “beating” process (such as in blacksmithing) is commonly known for changing the external shape of the metal. But it can also be used to modify the metal’s internal microstructures, such as to change their strength. However, the “beating” process can inadvertently destroy certain features of 3D printed metals, such as their complex shapes and internal structures that are difficult to produce with traditional methods.

Shubo sought to address this problem. Applying his prior training in materials science, he realized that similar to what happens in blacksmithing, microstructures of the metal could be reconfigured by causing the metal to rapidly expand and shrink as it heats up and cools down during the 3D printing process. He theorized this could be done by adjusting a 3D printer’s energy source, like a laser beam, to melt layers of metal powder to 3D print a metal part.

While this controls whether gaps form in the metal, the researchers showed that adjusting the laser also changes the type of microstructures that form in the metal after it is heated — one structure that makes the metal stronger and another that makes it mechanically weaker. They also remelted the printed metal layers to encourage the changes in the metal’s microstructures. Reserarchers’ experiments with 3D printed stainless steel confirmed Shubo’s theories.

And, because 3D printing enables each layer of printed metal to be printed in exact ways, the characteristics of each 3D printed metal can be fine-tuned to a different level at different specific points in the metal, which is impossible with conventional manufacturing processes.

The scientists were thus able to use 3D printing techniques and tweak printing parameters to produce a 3D printed metal with different microstructures that create stronger and weaker regions in the exact locations in the metal that they wanted.

“Our strategy can target specific sites in the metal, which allows manufacturers to design and create complex microstructures that allow the properties of the metal to be customized to a degree not seen before. For instance, the same metal can have contrasting properties in the same part,” Shubo says.

Theoretically, the strength of such a printed metal part should be between that of materials with only strong regions and those with only weak regions. However, the research team found that 3D printed metals with both strong and weak regions were slightly stronger than metals with only strong regions.

This synergistic interaction between strong and weak regions in the printed metal points to the potential of the new technique for making stronger and tougher materials than those described by the classical rule-of-mixture theory for composite materials comprising different materials.

The researchers believe their method can also produce printed metal with different functional properties. For example, a metal part could be printed so that the section submerged in seawater is more corrosion resistant, while other sections above water are less corrosion resistant.

Future work that could be done that includes testing if the method can produce 3D printed metals with other types of new microstructure designs that can lead to metals with even better mechanical and functional properties.

- Read about the NTU research into a 3D printing method for complex metal-plastic composite structures. Researchers from Japan and Singapore developed a new 3D printing technique to create precise patterns on the external and internal surfaces of 3D plastic structures.

- Learn about the HP corporate innovation lab in Asia at NTU. HP’s first university laboratory collaboration in Asia will focus on digital manufacturing technologies, from 3D printing to machine learning and more.

Related Content

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreThis Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More