President Biden to Announce Additive Manufacturing Initiative on Visit to Cincinnati

President Joe Biden is set to announce AM Forward, an additive manufacturing initiative, during a visit at United Performance Metals in Cincinnati, Ohio.

President Joe Biden is expected to announce during a visit to United Performance Metals near Cincinnati, Ohio, on Friday that five U.S. manufacturers have made commitments to purchase additively manufactured parts from smaller, U.S.-based suppliers.

GE Aviation, Honeywell, Lockheed Martin, Raytheon and Siemens Energy are the initial participants in AM Forward, the White House initiative that aims to strengthen domestic manufacturing and improve supply chain issues through the adoption of additive manufacturing. In addition to direct purchasing, the five manufacturers are also committing to training their suppliers’ staffs on new additive technologies, providing technical assistance and engaging in the development of common standards and product qualifications.

The LEAP engine fuel nozzle, pictured here, is often assumed to be the first part that GE Aviation identified for additive manufacturing (AM) and produced this way. But the company printed T25 sensor housing units for more than 400 GE90 engines well before it printed its first LEAP fuel nozzle tips. Photo: GE Aviation

According to the White House statement, “AM Forward is a completely voluntary compact open to any OEM to participate, provided they are willing to make public commitments to support their suppliers’ adoption of additive capabilities.”

What is Additive Manufacturing?

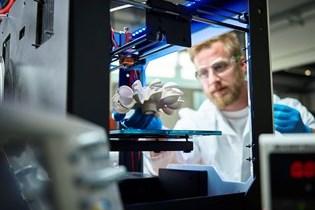

“Additive manufacturing” (AM) describes the use of 3D printing to make functional components, including tools and end-use production parts. Unlike “subtractive manufacturing” processes such as machining, where parts are created by removing material, additive manufacturing builds geometries by “adding” feedstock such as filament, wire or powder. Read more

Related Content

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

-

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

-

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.