Covestro Sells Additive Manufacturing Business to Stratasys

The sale includes R&D facilities as well as offices and employees in Europe, U.S. and China.

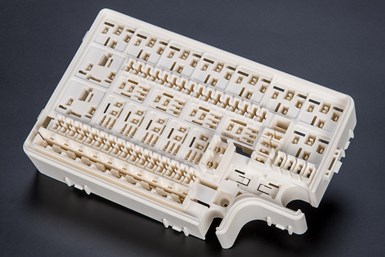

Fuse box made of polybutylene terephthalate from Covestro, produced by laser sintering on a Farsoon machine. Photo Credit: Covestro

Covestro says it has signed a definitive agreement to sell its additive manufacturing (AM) business to Stratasys. With the decision to sell the AM business, Covestro says it is continuing its portfolio optimization in order to position itself even more efficiently in the market and be able to place greater focus on its extensive offering for customers in its core industries.

“Additive manufacturing is a growing but also highly competitive market,” says Dr. Thomas Toepfer, Covestro CFO. “We are convinced that Stratasys offers the optimal conditions to support the further growth of our former additive manufacturing business in this field.”

Covestro's divested business includes employees, research & development facilities, production assets and offices in the Netherlands, Germany, the U.S. and China, as well as access to a network of global partners. The business offers material solutions for common polymer 3D printing processes. The portfolio of the AM business also includes products from the resins and functional materials business acquired from DSM in 2021, which includes brands such as Somos and Addigy.

The transaction is planned to be closed in the first quarter of 2023.

Related Content

-

IndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

-

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

-

Sinter-Based Additive Manufacturing Finds a Place Alongside MIM, Press and Sinter at APG

Powder metallurgy company Alpha Precision Group (APG) is applying a particular class of metal 3D printing technology for both rapid iteration in development and flexibility in production.