3D Systems, Klarity Partner to Expand Access to Patient-Matched Radiotherapy Innovations

Klarity has added 3D Systems’ VSP Bolus to its radiotherapy solutions, enabling radiotherapy clinics in the U.S. and Canada to embrace 3D printing technology without investing in costly, time-consuming software.

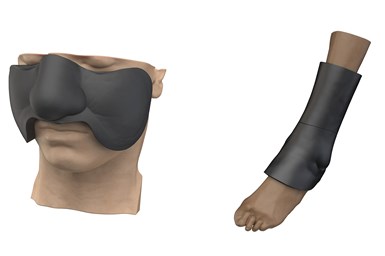

The Klarity Prints VSP Bolus product is 3D printed to the exact treatment plan bolus dimensions from a soft, biocompatible material that contours to the patient’s anatomy for an improved treatment experience for providers and patients. Photo Credit: 3D Systems

3D Systems is partnering with Klarity, a provider of radiation therapy solutions, to expand the distribution of its FDA-cleared VSP Bolus solution. Klarity will offer VSP Bolus within its new line of high-quality, patient-specific 3D printed products called Klarity Prints.

The Klarity Prints powered by 3D Systems is a service-based line of 3D printed radiotherapy accessories (such as VSP Bolus) which does not require specialized software or hardware, enabling radiotherapy providers to focus on patient care.

3D Systems developed VSP Bolus to deliver 3D printed, biocompatible, patient-specific boluses that can improve therapy modulation, decrease technician time and enhance patient comfort. Through the distribution agreement with Klarity, this 3D printed solution is now available to radiotherapy clinics across the U.S. and Canada.

Klarity’s team of experts is known in the radiation oncology market for providing excellent customer service with a focus on delivering solutions to medical professionals that improve cancer treatment. Once interested clinics contact their Klarity account manager, orders can be initiated quickly and the patient-specific bolus is delivered within a few days.

The established workflow leveraging patient treatment plans created by

radiotherapy professionals frees clinicians from the time-consuming task of manipulating objects in specialized software and fabricating the accessory themselves. The Klarity Prints VSP Bolus product is 3D printed to the exact treatment plan bolus dimensions from a soft, biocompatible material that contours to the patient’s anatomy for an improved treatment experience for providers and patients.

“This collaboration aligns perfectly with Klarity’s ongoing commitment to improving the quality of care provided by our customers,” says Peter Larson, Klarity CEO. “As a North American distributor of 3D Systems’ 3D printed biocompatible bolus products, we will be at the forefront of advancing personalized care and improving the patient experience.”

Klarity has a strong reputation in the radiation oncology sector for delivering superior products and service. “The company’s commitment to improving patient care through treatment personalization aligns with 3D Systems’ market-leading service model for delivering high-quality, 3D-printed, patient-specific medical devices for over two decades,” says Menno Ellis, 3D Systems’ EVP, Healthcare Solutions. “We’re pleased to partner with Klarity to provide next-generation radiotherapy accessories to patients undergoing treatment across the U.S. and Canada.”

Klarity is a provider of radiotherapy products that provide clinics with improved solutions for patient positioning, treatment planning, brachytherapy and custom devices.

Related Content

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).