3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Share

This episode of The Cool Parts Show brought to you by Carpenter Additive

The springiness of foam is a material property employed for padding in protective helmets. But could a better, more precisely engineered springiness — that is, more carefully controlled compliance, elasticity and resilience — be achieved through geometry instead? The engineering firm General Lattice is realizing this possibility. The company is developing expertise in what it terms “digital materials”: engineered lattice forms made with various 3D printing processes to realize specific mechanical properties that otherwise might be inherent to the material. One promising application is padding for helmets. To serve this need, General Lattice tailors lattice forms to the type of protection the helmet has to provide, whether that is for safety against a collision or against more concentrated impacts. Meanwhile, padding made via 3D printing in this way can also be customized to the wearer by designing from a scan of the head. We experienced this with digital-material helmet padding that was made from our personal scan data. Watch this episode of The Cool Parts Show to see, among other things, Stephanie and me getting our heads examined.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Design and engineering firm General Lattice

- AM Radio conversation about 3D printed lattices replacing foam

- 3D printing for insoles customized to individual feet

- X-ray view of lattices within a 3D printed shoe

- Reviewing the unexplored frontiers of lattice fabrication

Transcript

00:00:00:02 - 00:00:00:13

Peter Zelinski

I’m Pete.

00:00:00:23 - 00:00:13:20

Stephanie Hendrixson

I'm Stephanie and this is The Cool Parts Show our show all about innovative, unusual, unique and protective 3D printed parts. You might notice there's something a little bit different about our wardrobe this episode. But don't look at the helmets. Look at the padding.

00:00:14:06 - 00:00:27:05

Peter Zelinski

The padding isn't foam. These are 3D printed lattice structures providing the protection in 3D printed structures tailored to the different needs of these different helmets and tailored to our heads.

00:00:27:14 - 00:00:31:01

Stephanie Hendrixson

We're talking about digital materials on this episode of The Cool Parts Show.

00:00:49:00 - 00:00:57:09

Stephanie Hendrixson

Thanks for joining us. If you haven't already, make sure to subscribe so you get notified about our new episodes. Today on the show, we're going to be talking about the 3D printed pads inside of these helmets.

00:00:57:18 - 00:01:15:17

Peter Zelinski

Right. We're going to talk about 3D printed padding. And there's a lot to talk about. But first, we are launching something new, starting with this episode, something new for fans of the show. We're going to tell you about it. Stick around to the end of the episode. So 3D printed padding. Where should we start?

00:01:16:05 - 00:01:29:05

Stephanie Hendrixson

As we said in the cold open, the helmets are not the point. The padding is the point. The pads in these helmets are made from 3D printed lattices. This is 3D printing as a replacement for foam, and it's an example of something called a digital material.

00:01:29:13 - 00:01:47:05

Peter Zelinski

So the helmets are standard. They're off the shelf, but the padding is customized. The structure of these lattices is engineered for the needs of the helmet, engineered for the wearer. And it's all the work of a company that knows a lot about 3D printed lattices.

00:01:47:17 - 00:02:04:07

Stephanie Hendrixson

They're called General Lattice and they're headquartered in Chicago, and they started out as a contract manufacturer but found they were spending so much time helping customers design their parts that they wanted to just lean into that. So now they're more of a design, more of a software company specializing in these digital materials.

00:02:04:19 - 00:02:21:22

Peter Zelinski

Digital materials. Let's talk about that. That's what's kind of radical here. We are accustomed to something like the softness, the springy-ness of padding coming from foam, but here it comes instead from the design, the way that these 3D printed structures are engineered.

00:02:22:11 - 00:02:28:12

Stephanie Hendrixson

Let's hear more about that. Here are Merrik Moffett and Nick Florek, the CTO and CEO of General Lettuce.

00:02:29:02 - 00:02:54:03

Nick Florek

General Lattice has been a number of things over the years. We started off as a contract manufacturer and really what we've evolved into today is a digital materials company. And so when we talk about digital materials, we're talking about using geometry paired with existing commercially available hardware and materials to start to alter and change the mechanical response of those 3D printed materials through the use of geometry.

00:02:54:08 - 00:03:07:01

Marek Moffett

The idea that you can actually change the mechanical property of a base material just by changing the shape or geometry is what a digital material is.

00:03:07:08 - 00:03:28:07

Stephanie Hendrixson

So when we're talking about digital materials, we're not talking about like a solid block of metal or some resin or even like a 3D printing filament. We're talking about materials that are getting some of their properties from their chemistry and some from their geometry. So when we visited General Lattice for this episode, we walked in and they weren't formulating new materials, they weren't making powders or anything like that.

00:03:28:12 - 00:03:38:18

Stephanie Hendrixson

Instead, as a digital materials company, they're really zeroed in and focused on figuring out the geometries that are going to deliver the right material properties for specific applications.

00:03:39:05 - 00:04:05:05

Peter Zelinski

Figuring out the geometry. That's right. That is what's so radical about this. That phrase, digital materials is useful because it captures this way that we're accustomed to thinking about materials being one thing and the geometric design being something altogether different. And the materials have material properties like the softness or springy-ness of foam for padding is a material property.

00:04:05:12 - 00:04:20:11

Peter Zelinski

Here is something altogether different. That same property achieved instead through the design of the structure, the design of the form, the digital design used to achieve a property, we otherwise associate with the material.

00:04:21:00 - 00:04:27:01

Stephanie Hendrixson

And there are lots of potential applications for this concept. Foam replacement just happens to be a really good use case.

00:04:27:18 - 00:04:55:05

Marek Moffett

Digital materials are a great replacement for traditional foam applications, especially in helmet applications because of three real main benefits, one being biometric customizability. So the pad being able to actually fit your head, that's a really great benefit because even if your pad meets the mechanical properties that it needs to, if it's not touching your head all the way around, you're not going to get the results you need.

00:04:55:14 - 00:05:22:07

Marek Moffett

So that paired with true mechanical property that's necessary for not even the whole pad structure, but a specific place, coupling that with biometric data is a real mechanical property benefit overall. And then finally, just the sort of ergonomic breathability of the pads in general. We have a lot of great feedback in terms of reusability, breathability and cleanability.

00:05:23:04 - 00:05:40:13

Stephanie Hendrixson

So 3D printing as a way of applying this digital material concept, it gives you the design freedom that you need to really easily manipulate your material properties and get the material to do the things that you need it to do. But 3D printing also makes it a lot easier to customize whatever it is that you might happen to be making.

00:05:40:13 - 00:05:43:03

Stephanie Hendrixson

And we got some firsthand experience with that for this project.

00:05:43:16 - 00:05:50:14

Peter Zelinski

Nick talked about personalization. The padding in these helmets was personalized to us. So first step, we got our heads scanned.

00:05:51:02 - 00:06:07:10

Stephanie Hendrixson

Yeah. Thank you to Exact Metrology here in Cincinnati, they scanned both our heads and the interior of the helmets with the off the shelf pads removed. They needed to do both so that General Lattice would have an idea of their sort of design envelope, how much volume they have to fill with these pads.

00:06:07:19 - 00:06:17:07

Peter Zelinski

Yeah, this is literal personalization because that design envelope was the space between the inside of the helmet and the outside of our skulls.

00:06:17:22 - 00:06:55:00

Marek Moffett

So once we received the scan data from the helmets and of your guys heads, we took it into Rhino Grasshopper 3D and basically ran through a custom script that we've written that allows us to reference our Frontier database and take those material ID’s and populate the pads with the appropriate data that we need and ultimately print them. So the process was get the scan data set up some pad design spaces, find the appropriate materials that we want to put in those design spaces and ultimately integrate those.

00:06:55:23 - 00:07:07:03

Stephanie Hendrixson

So customizing the pads to fit between our heads and the helmets was a big part of the tailoring that happened here. But these pads are also tailored for two different applications for two different sports that are represented here.

00:07:07:10 - 00:07:27:05

Marek Moffett

So in the race helmet, these impacts are designed for one large impact that you need to survive one time, not repeated over and over again. Smaller sort of impacts. And so with the data we collected, we were able to find a structure that met those criteria and we're able to implement that within the shape that, okay, this is a race helmet,

00:07:27:05 - 00:07:52:07

Marek Moffett

We're looking for one one big impact that it needs to protect its wear where a baseball helmet will take more repeated and over and over again impacts where we went through our data and found the appropriate unit, cell or lattice to actually go and put within the design space. And so between those two lattices, the densities change quite differently. There's thickness differences as well as weight.

00:07:52:07 - 00:08:00:17

Nick Florek

What we're able to do is dynamically tune the mechanical response of the digital material independent of the application.

00:08:00:17 - 00:08:08:02

Nick Florek

And so that enables us to again, be very specific in terms of how we're leveraging the digital material for each application set.

00:08:08:20 - 00:08:14:12

Stephanie Hendrixson

So Photocentric 3D printed these pads, General, Lattice glued them into the helmets and shipped them to us.

00:08:15:02 - 00:08:40:16

Peter Zelinski

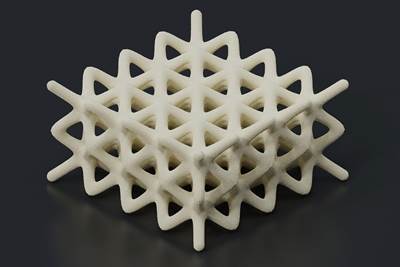

Photocentric 3D printed the padding through digital light processing, DLP, with a flexible polymer. We should say also, General Lattice has developed lattices for other 3D printing processes too. Here’s selective laser sintering. Multijet Fusion. General Lattice doesn't do any of the 3D printing themselves, and that fact kind of points to what their role is in the process.

00:08:41:02 - 00:09:10:04

Peter Zelinski

Marek mentioned Frontier. That is their name for General Lattices database of the different lattice structures that they have developed through engineering, through testing, and so they bring all of this intel about different lattice forms, the ways that they can be tuned, the different resiliency, springy-ness, properties they achieved when they're used through various different 3D printing processes.

00:09:10:16 - 00:09:49:20

Marek Moffett

So Frontier is a digital material library that is free and we want everyone to use. And the idea is that it's designed to drop the bar of lattice structure adoption. So currently how that works is that a design engineer will have to go and learn or purchase a new piece of software that they again have to spend quite a bit of time getting comfortable with to ultimately generate a handful of swatches or samples that they have to go and then get printed, then get validated, physically tested or potentially even digitally analyzed.

00:09:49:23 - 00:10:17:13

Marek Moffett

But that process is extremely painful. It's expensive. So the goal of Frontier is to lower that bar for everyone instead of going to do your own research and own creation of these materials. Can we get ahead of that and say, okay, don't go do all of this research that we've already done. If you can just search for a mechanical property that you know or are looking for, let us get you there a lot, lot quicker.

00:10:17:18 - 00:10:29:19

Marek Moffett

And so ultimately, the database will not only show a design engineer that these properties exist, but ultimately will have a way to integrate that material into their part.

00:10:30:15 - 00:10:51:03

Stephanie Hendrixson

So anyone can search Frontier for a digital material for their specific application. But General Lattice is also taking this a little bit further and developing some really specific digital materials for even more targeted types of applications. So the foam that is inside of both of these helmets, even though it's been tuned differently, it's all one product called Foam X.

00:10:51:11 - 00:11:18:03

Nick Florek

So Foam X is a what we would call pro material. So a pro version of a digital material. The idea is that these pro materials are developed further, have gone through additional testing and evaluation that's very specific to an application. And so the idea is to create a technology where any helmet company can license Foam X from General Lattice and have it seamlessly integrated into their existing helmet designs.

00:11:18:03 - 00:11:46:02

Nick Florek

They don't have to go around and retool the helmet just to adopt this new padding, but they can actually bring that padding into the existing design space and increase the safety and performance of the helmet within a very short time span. And again, what this does is help eliminate all of the R&D work that they would have to go out and do themselves where we can again, bring this to market in a way that's akin to like a Gore-Tex technology where many companies can license that and use it within their product.

00:11:46:21 - 00:12:09:09

Peter Zelinski

So Foam X is their product of foam replacement and tunable for different foam needs. Our different helmets have different needs. So my racing helmet needs to protect against collisions and your batting helmet needs to protect against stray pitches. But there are other applications General Lattice sees for this idea.

00:12:10:03 - 00:12:39:10

Nick Florek

Yeah. So outside of head protection, we're very interested in the footwear space as well as specialty packaging. So when you look at hard shell cases that are transporting high dollar assets, I think there's a real opportunity to replace foam in those. We're also starting to expand our knowledge base into rigid polymers and into metals. So looking at thermal applications and doing more work within the federal government to kind of build that initial knowledge base that we ultimately transfer into our Frontier product.

00:12:40:13 - 00:12:52:02

Peter Zelinski

I think we got this. This is a 3D printed geometric replacement for foam. The padding effect comes from this lattice structure, this 3D printed form.

00:12:52:16 - 00:13:18:11

Stephanie Hendrixson

This is an example of a digital material, something that gets some of its material properties from its physical geometry. These pads were developed and designed for us by General Lattice, a company that specializes in manipulating material properties. By altering the geometry, they're working on a database of multiple different types of lattices, multiple types of digital materials that can be applied in many use cases beyond just sports helmets.

00:13:19:07 - 00:13:28:00

Peter Zelinski

Thanks for watching. And now, as we promised at the start of the episode, we want to tell you about something new. We're launching The Cool Parts Show All Access.

00:13:28:09 - 00:13:43:21

Stephanie Hendrixson

That's right. All Access is a free subscription for our fans. That's you. If you sign up at TheCoolPartsShow.com/AllAccess, you’ll get access to behind the scenes footage, to exclusive interview clips with our experts, and you'll be able to watch all of our new episodes early before they premiere on YouTube.

00:13:44:02 - 00:14:13:01

Peter Zelinski

We do these episodes and we routinely find that we have these interesting segments of things our interviewees have shared that we can't find a place to use in the show and now we can put them in All Access and share them that way. So for example, from this episode, there is this moment where Marek talked about the way that the surface of this 3D printed padding, it doesn't end in just broken lattice forms.

00:14:13:01 - 00:14:25:21

Peter Zelinski

It comes to kind of a smooth closure. There are some design issues that go into that that are wrapped up in that, and Marek elaborates on that. So go to All Access, register, and see him talk about that.

00:14:26:03 - 00:14:39:17

Stephanie Hendrixson

And if you've been a fan of the show for a long time, there's some stuff up there already from previous episodes. There's things going all the way back to the creation of this thing called The Cool Part Show, and there's more to come. So sign up at TheCoolPartsShow.com/AllAccess, and we'll see you behind the scenes.

Related Content

Preassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read MoreVelo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

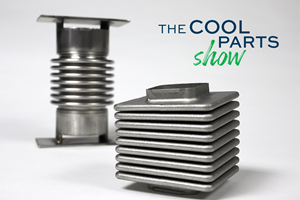

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreRead Next

3D Printed Lattice Structures Replace Foam Components: AM Radio #9A

On this episode of AM Radio, Stephanie Hendrixson and Julia Hider examine the use of 3D printed components with lattice structures to replace foams.

Read MoreFrontier Digital Materials Platform Includes Searchable Lattice Library

The digital materials platform eliminates costly guess-and-check workflows by enabling users to search, analyze and order physical samples of lattice structures for hands-on evaluation, saving time, money and resources.

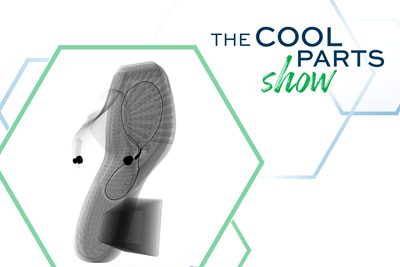

Read MoreAn X-Ray View of Lattices and String Lasting: The Cool Parts Show Bonus

One recent cool part concealed most of its complexity. Take a look inside in this bonus episode.

Read More