Frontier Digital Materials Platform Includes Searchable Lattice Library

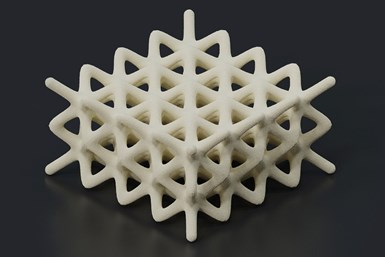

The digital materials platform eliminates costly guess-and-check workflows by enabling users to search, analyze and order physical samples of lattice structures for hands-on evaluation, saving time, money and resources.

General Lattice has released the beta version of its Frontier digital materials platform. Designed to drive the adoption of additively manufactured applications, the platform democratizes the use of lattice structures by treating them as traditional materials with tangible properties.

Frontier provides a free-to-search library of validated mechanical property data to support users in the selection of the best lattice, material and hardware combination. Users can search, analyze and order physical samples for hands-on evaluation. Eliminating costly guess-and-check workflows, Frontier finds the lattice structure variation, saving users’ time, money and resources.

The company says the future of manufacturing is undeniably digital and digital materials delivers a leap in product development capabilities. Offering performance and dynamic tunability, digital materials provides a new dimension to material science and utilize the unique strengths of additive manufacturing (AM).

Partnering with industry-leading hardware and material companies, Frontier provides a centralized source for validated digital material information. Initial platform partners include EOS, BASF Forward AM, and Photocentric with an emphasis on understanding digital materials comprised of elastomeric polymers targeted toward foam replacement applications.

“These tools will reduce the effort and costs to replace foam via drop-in lattice solutions, as well as reduce waste generated by physical prototype iterations,” says Dave Krzeminski, Ph.D., senior additive minds consultant at EOS.

As the Frontier platform continues to expand, additional partners will be added and the breadth of digital materials will grow to include metals, ceramics and composites.

Frontier (BETA) is available at frontier.generallattice.com. A full version with integration capabilities will become available later in 2023.

- Read about how General Lattice’s enterprise solutions team worked with Wilson to create the first airless prototype basketball. The team was able to its concept to life by streamlining the design and iteration process through the use of its computational design tools and workflows.

Related Content

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

Concept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).