AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Share

What Is Digital Light Synthesis (DLS)?

Digital Light Synthesis (DLS) is a proprietary resin-based 3D printing process developed by Carbon. DLS 3D printing uses the Continuous Liquid Interface Production (CLIP) technology also developed by Carbon.

How Does DLS 3D Printing Work?

Digital Light Synthesis is based on stereolithography and like that process is also a type of vat photopolymerization. Both processes use UV light to cure resin. Unlike stereolithography, however, Carbon’s DLS 3D printing doesn’t pause after each layer. Instead, the resin continuously flows through a “dead zone” just above the oxygen-permeable window, as shown below. UV images representing the cross-section of the part are projected onto an oxygen-permeable window to solidify the resin. Parts are built upside-down, as the build platform rises from the vat of resin.

Welcome! You’ve unlocked premium content.

These nozzles for cleaning Vitamix blenders were 3D printed using Carbon’s CLIP printers at The Technology House. The process has also been used for Adidas shoes, medical devices, Ford car parts and much more. Photo Credit: Carbon

What Materials Can Be Used?

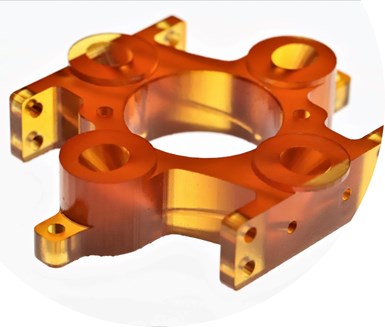

This component made for NASA’s Seeker robot was printed from Carbon’s CE 221 cyanate ester material. The part must withstand high and low temperatures as well as cold-gas propulsion for thrust when flying. Two are used on each Seeker. Photo Credit: The Technology House

DLS resins available from Carbon include elastomeric, flexible, rigid and medical-grade polyurethanes; silicone; cyanate ester; epoxy; urethane methacrylate; and dental materials.

What Postprocessing Is Required?

After printing, the parts are cleaned of resin and freed from the build plate. Any supports are removed. UV-curable resin parts are complete at this stage. Many materials, however, require a thermal post-cure in an oven; this can take from 4 to 13 hours to complete. The heat sets off a secondary chemical reaction that strengthens the parts. Typically no further postprocessing is required after cleaning and curing.

Most resins used with DLS are two-part resins: They are initially cured by UV light inside the printer, but then require a thermal postcure in an oven to set their final properties.

Why Use Digital Light Synthesis?

The continuous nature of Carbon’s DLS 3D printing process avoids the creation of layer lines in the part, offering a surface finish comparable to injection-molded parts. According to Carbon, DLS parts are also watertight and isotropic, having the same strength in all directions.

In addition to providing a means of making prototypes, DLS can be used for bridge production before molds are available, or as an alternative for making production parts that would otherwise be injection molded.

The Adidas 4DFWD line of running shoes uses latticed midsoles that are 3D printed using DLS. Photo Credit: Adidas

What Are the Applications for DLS 3D Printing?

Digital Light Synthesis has been applied to prototype and produce medical devices; mouth guards and other dental implements; COVID swabs; shoe midsoles; automotive brackets; food service devices; gaskets and other flexible components; parts for space; and more.

Related Content

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

.jpg;width=70;height=70;mode=crop)