Titanium Cheaper Than Aluminum? The Cool Parts Show All Access

General Atomics’ Steve Fournier describes how directed energy deposition makes titanium economical for aircraft structural components.

WatchWhat Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreFor Scale Production Via AM, Are Big Machines or Small Machines Better?

One choice offers more build volume and longer unattended runs. The other offers a tighter space to control and more frequent turns. In this LinkedIn post, here are various applications examples of both, plus views from readers.

Read MoreVideo: AM for Harder, Longer-Lasting Brake Discs

Additive manufacturing is being applied to limit automotive brake dust. For a major automaker, Etxetar and Talens are developing a production-speed directed energy deposition system to give brake discs a precise layer of wear-resistant carbide.

WatchVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Watch3 Attributes of the “Second Wave” of AM Part Producers

Successful contact manufacturers in additive look more and more like successful contract manufacturers in general.

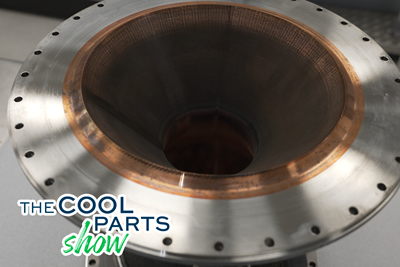

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

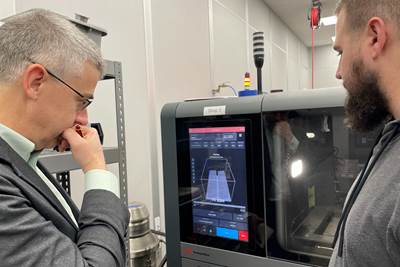

WatchHow to Rapidly Calibrate 4-Laser Production LPBF Machines

Multi-laser machines introduce an additional source of variation; the separate lasers have to synch with one another. At this Indiana additive manufacturer, one-third of the laser powder bed fusion machines are multi-laser. Here is is the AM calibration tool this company uses.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

Watch