Is additive manufacturing (AM) ready for scale production? Yes — but the method’s readiness doesn’t mean it is a plug-and-play solution for any business. Bringing 3D printing into a production situation requires groundwork; in addition to the hardware, software, materials and infrastructure required, any would-be additive manufacturer also needs to adopt an additive mindset that permeates through the organization, from design through shipping.

In the video below, editor-in-chief Peter Zelinski and I discuss production AM from a high-level perspective. We cover 3D printing technologies and materials commonly used for production today; auxiliary equipment and steps needed to build out the full additive manufacturing process; organizational issues around implementing AM; and how trends such as machine learning and sustainability will grow with and advance alongside additive.

Watch the video for a primer on additive manufacturing for production, and consult the Resources & Related Links for deeper dives into the companies and businesses successfully putting AM into practice.

Resources & Related Links

- More information on the examples and issues surrounding AM for production discussed in this video

- Our ongoing collection of production 3D printing use cases and success stories

- How industries ranging from automotive to consumer products are using 3D printing to manufacture end-use items

- Parts that exemplify 3D printing’s advantages on The Cool Parts Show

Transcript

Peter Zelinski, Additive Manufacturing

I’m Pete Zelinski.

Stephanie Hendrixson, Additive Manufacturing

And I’m Stephanie Hendrixson. We’re with Additive Manufacturing Media and The Cool Parts Show.

Peter Zelinski

Today we're going to talk about additive manufacturing for production: additive manufacturing as an option for making end-use parts at production scale. This is an option available alongside conventional manufacturing processes for new products coming to market, for manufacturing operations that are being re-engineered — but it is production that looks different, behaves different, has different expectations and brings different opportunities compared to the manufacturing processes we understand. We talk about all the different facets and issues of this on AdditiveManufacturing.media, but what we're going to do now is have kind of a high-level conversation looking at all of the issues and aspects of additive manufacturing for production. So Stephanie, get us started, we’re talking about “production additive manufacturing.” What are we talking about there?

Stephanie Hendrixson

I think it's helpful to look back at the history of 3D printing. 3D printing starts as rapid prototyping, where it's just a technology to really quickly iterate your designs and get to that final prototype. Then, you're going to go into injection molding or some other technology to to make the end product. So when we talk about additive manufacturing for production, we're talking about actually making that end-use part — the thing that you're printing is the thing that's ultimately going to go into the assembly of that product, or it's going to go straight to the consumer. The role of the printed thing has changed.

There's also a way that quantity can play into this. I mean, if you're printing one replacement part for a legacy system, that's technically production. We've also seen instances of what's called bridge production, where you're using 3D printing to make maybe an initial run of a product before you go to another process. But generally, and I think for the purposes of this conversation, when we talk about production AM, we mean additive manufacturing: that is, the sole manufacturing method for something that's needed in the hundreds, the thousands, the tens of thousands and upward from there.

Peter Zelinski

So that's right. You started by talking about prototyping, and 3D printing is still every bit a prototyping resource, in addition to now a production resource. When the same platform does prototyping that also does production, then that sort of boundary line between “what is prototyping” and “what is production,” it can get blurry — and it's good and helpful for it to get blurry, sometimes. The design of the part can be finessed longer and farther and later into a product's introduction. That works even in cases where additive manufacturing might not be the sole ultimate production process, when some conventional process might take over at the highest volume. You mentioned bridge production, the opportunity to use additive manufacturing to do production, at least in initial quantities. As additive manufacturing gets better and better at that and more and more accessible for production, that bridge can reach farther and farther before conventional manufacturing has to take over.

Stephanie Hendrixson

Yeah, absolutely. When, you know, the technology has advanced and the materials have advanced to the point that you can be making your prototype— then, once you've nailed that design, you can just keep printing it as a production part without changing the platform or anything else about it. But you talked about how that line is blurry, it's fuzzy between what should be 3D printing and what should be a conventional process. So let's talk about that a little bit about that. What are the best use cases for additive manufacturing?

Peter Zelinski

The very best use case for additive manufacturing for production involves a production part that was conceived for additive manufacturing from the beginning, that was designed to take advantage of the opportunities that 3D printing brings. So that means it starts with design. It starts with design for “can I take advantage of additive, the opportunities for geometric complexity that it brings, to realize maybe a lighter weight form that uses less material, a form with more internal complexity that is useful?” That's the design of the part.

But then there's thinking about downstream operations after 3D printing, “is there opportunity there to simplify the process?” Also in design — I guess I'm thinking about assembly — “is there the chance to consolidate assembly into a single, complicated 3D-printed form that maybe takes the place of an assembly operation that potentially brings a lot of little pieces together later,” consolidating assembly, but then there's also the rhythm of production.

I think maybe that's one of the biggest and most fundamental changes with additive: additive is a digital process, it is a tooling-less process. A process like molding and even a process like machining requires an upfront investment in tooling, requires sort of an early commitment before production begins. Additive doesn't have any of that — doesn't have any tooling. And the result of that is, it is possible to go to market and to launch a product with a much smaller initial production quantity than maybe you think you could get away with. It's also possible to leave the design tentative or open much later than you think without dedicated tooling. It's possible actually to be entirely in production, but still be changing and refining the design as needed.

But I think we're getting a little ahead of ourselves, because there's a basic point we want to touch on: additive manufacturing, what does it mean? It means making stuff with 3D printing. What 3D printing options are amenable to this? What are the additive processes that make sense for production?

Stephanie Hendrixson

Yeah, so that's a really good question. I think maybe the best way to answer it is to split it up by material. So the main categories of materials you'd be working with would be metals or polymers. There are also systems that print with composites and ceramics, but metals and polymers are kind of the main ones where those high-volume production applications are happening.

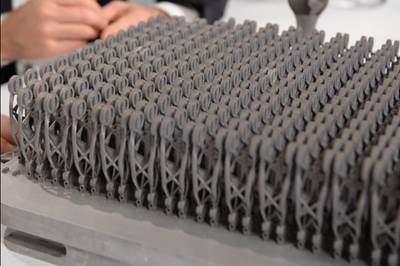

So on the plastic side, we see a lot of powder-based processes where you're working with a bed of powder. These include selective laser sintering, where you've got a laser that is melting the specific areas of powder that need to be melted for each layer. Multi Jet Fusion, which is a proprietary process from HP, is sort of similar, but instead of using a laser, it's dropping this binding agent down into the powder, and then you fuse the whole layer at once. There are also the stereolithography and digital light processing techniques that use a liquid resin that's being cured into plastic.

I think what those processes have in common and why we see them so frequently used for production, is that they allow you to batch a lot of parts. You can pack a lot of parts onto your build plate or maybe into your full build volume. So if you need hundreds or thousands of something, you could maybe print 50, 100 or 200, all at once within one machine and in one build.

On the metal side, sort of similarly, you have some powder-bed processes like selective laser melting, electron beam melting; it’s a very similar idea where you just have a higher powered laser or an electron beam that's doing that that fusing. There's also binder jetting, which we're seeing more and more of lately, where you have powdered metal and then you're dropping some kind of binder or glue into it that is eventually going to get burned away as you center the part into its final dense metal form. And then we also see things like directed energy deposition, where it's almost kind of a welding process where you're applying powdered metal and metal wire to build up the part. That's typically used for things that are needed in lower volumes, but that are larger in size. So structural components, something that's not going to easily fit into a powder bed.

At kind of a high level, those are sort of the main material categories and some of the key technologies that we see being applied.

Peter Zelinski

Yeah, additive manufacturing, 3D printing, it's a broad term that covers a lot of ways of building a part. People think of 3D printing, and the first image that comes to mind is a desktop 3D printer using an extruder nozzle moving in an XY plane to build up layer by layer. And when we talk about production additive manufacturing, we're frequently referring to industrial 3D-printing processes that don't necessarily look like that. Except that process I'm describing, the extruder nozzle and laying down material — FDM is one term that's used to label that. Even FDM technology is getting faster and is being applied to production.

Stephanie Hendrixson

Yeah, absolutely. I talked a lot about how these production technologies let you batch lots of parts at once. And with FDM, fused deposition modeling, that's not necessarily the case. But what we see is people scaling to production with that technology just by having lots of different printers, instead of packing more things into one printer.

Peter Zelinski

Yeah, that's right. The printer farm as a production platform.

Stephanie Hendrixson

Exactly. Okay, so like there's a real diversity of processes that can be used for production AM, but they all do have some things in common. What are some of those common issues that manufacturers have to think through when they want to apply 3D printing for production?

Peter Zelinski

I think it's well understood now that 3D printing — it's not just hit print, right? Additive manufacturing is an industrial process, there are manufacturing and engineering considerations that come into it, just like any industrial process. For additive, those considerations are — well, so it starts with design. I mentioned that in the context of the part, but that's true in the context of the process as well. Design considerations for achieving, for example, a repeatable process: Is there anything that you do to the design of the part or the design of the build that may moderate against little distortion effects that might be creeping into the build? Similarly, are there ways that you can design the build itself to get the most pieces into a single build, or to minimize the use of support structures?

Then another consideration is the parameters: with additive manufacturing there's a lot going on, because you are constructing the material properties at the same time that you're building the outer shape of the form. All that's happening at once, and it's the result of a lot of build parameters coming together and perhaps interacting in unexpected ways. It's a complex enough system that there's not really a cookbook approach to how to make a given part with a given additive process. Trial and error is still a part of process development. So how do you iterate that trial and error really fast? How do you do that quickly, and get a proven process as quickly as possible?

Inspection is another consideration: a part that is 3D printed is going to have to be validated in a different way. How do you assure an effective process both in the geometric form and inside the part? There's postprocessing, right? That is going to bring back in some of these conventional operations. A part that is 3D printed is liable to be almost complete, but not quite. What additional operations are needed to finish that part? We say it a lot, but additive manufacturing and 3D printing are not synonyms. Additive manufacturing ultimately involves considerations beyond just the 3D printer.

Stephanie Hendrixson

Right. So it's more than just the printer, but a lot of the steps that you just ran through also require equipment beyond the printer, right? So you might need new software packages, inspection equipment, maybe machining centers, EDM or some other postprocessing kinds of things. In addition, there are infrastructure concerns that you need to think about in the broader context. So if you're working with polymers, you know, depending on the temperature that you're running and the material that you're using, there's a danger that your machine could be emitting volatile organic compounds. That's something you don't want anybody to breathe. You might need to think about your air filtration, your ventilation, that sort of thing.

It gets a lot more complicated on the metal side, because metal powder is combustible. So you need fire suppression systems, operators are going to need respirators, fire-resistant clothing, other kinds of PPE like that. You're probably going to also need nitrogen or argon to enter the printing process, so then you need air monitoring systems to make sure there are no leaks in your facility. It’s a lot more than hitting print, it's a lot more than the printer itself. There's this whole ecosystem of equipment and procedures and things that you need to do this effectively.

Peter Zelinski

So, I started talking about the process considerations, and you very fittingly brought in the safety aspects of that. That kind of brings us to the people side of this: the people issues with adopting additive manufacturing, the organizational issues — which are kind of nuanced, but not inconsiderate. They might actually be the most important factor to succeeding with additive manufacturing. Additive manufacturing as a production process affects a lot more than just production, just manufacturing. It needs a champion. It is potentially such a transformation that it takes a champion, a leader to steward that transition through and that leader probably needs to be someone pretty highly placed. That leader might need to be the CEO because additive manufacturing is not just a manufacturing strategy, it is an enterprise strategy. And as we've kind of alluded to, it touches different parts of the enterprise.

We talked about design: certainly, design engineers have to think about the work they're doing differently if they know additive manufacturing is going to be the production process. They have a bigger window of possibility available to them, very different options available to them. So the way that a product is conceived from the very beginning changes if additive manufacturing is the production method.

There are inventory issues as well. A digital production process allows a lot more opportunity for production on demand, and maybe storing less, keeping less and even distributing your manufacturing to different places. And so if we're talking about inventory, we're also talking about aftermarket issues. Maybe your service parts organization and how that even works is all different now if you're free to 3D print a part as it's needed for a product that's already out there in the field.

Then there's the possibility for continually adapting the product, the possibility for not keeping the product design or a product line fixed, but changing very responsively to changes in the market. Again, a tooling-less process, there is no cost, there is very little cost to changing design as production proceeds and even when production is underway. All of that is so different, just the manufacturing engineers won't be enough to lead this different manufacturing process, somebody like the leader of the entire organization has to be able to say, organizationally, “Here's how we're making our product.”

Stephanie Hendrixson

Yeah, and that's a super disruptive scenario to be in. But it also presents all these other related opportunities. If you're going to explode the whole way your manufacturing business works, that also creates an opportunity to think about things like sustainability. So if you have to already rethink the design of your products, the materials that you're using, how much material you're applying to build that part and whether you're making it on demand versus storing it in inventory, that's an opportunity to make your business more sustainable. You can choose a renewable material and you can create more efficient designs, more efficient products. There are some real benefits that can come from thinking about additive manufacturing in conjunction with these other ideas.

You also mentioned distributed manufacturing, or decentralized manufacturing. Instead of having this one central factory where all of your tooling lives, and all of your production happens, and you're shipping products all over the world — if you don't have that tooling, then you can establish a couple of smaller 3D printing facilities close to where your customers and suppliers are, and much more easily transfer production from location to location. If there's some reason that one becomes inaccessible, or you just need to be more flexible about how you're making things and where you're making things, you can move.

Peter Zelinski

Right, because there's no tools. It's all just digital. Distributed manufacturing is a result of this freedom — you can shift production, relocate production just by moving the file around.

Stephanie Hendrixson

Yeah, yeah, this is digital manufacturing. I think the other interesting thing to mention here is that additive manufacturing, 3D printing, is still kind of a young technology. It's going to continue to advance as a virtue of being so digital. So we're seeing right now there are suppliers and organizations looking at ways of taking machine learning or artificial intelligence technology and figuring out ways of making the process better.

So you talked earlier about the trial and error that goes into parameter settings and that sort of thing. We're going to be able to get to those parameters faster because we'll have simulation tools, we'll have in-process monitoring, we'll have ways of letting 3D printers learn from their previous builds and teach each other how to do the process better. By virtue of being a digital process, additive manufacturing, maybe more so than any other manufacturing technology, is going to be able to benefit from the advance of software like that. It's only going to get more reliable, more dependable, and we're going to see more production happening with 3D printing because of that.

Peter Zelinski

Additive manufacturing for production. There're some real advantages available today: design freedoms, responsiveness to the market and the freedom to produce at much lower quantities and adapt production much more nimbly. But in addition to that, there are some future benefits you alluded to: the chance to manufacture more sustainably, the chance to distribute manufacturing geographically to take advantage of freedoms to manufacture in different locations as needed and the chance to benefit as fully as possible from some manufacturing capabilities related to AI that are arriving in the years to come.

Stephanie Hendrixson

Yeah, so I think we'll leave it there. This has been kind of a high-level look at how 3D printing is being applied for production. But if you'd like to learn more, you can find additional information at AdditiveManufacturing.media, TheCoolPartsShow.com and the links on this page. Thanks for watching.

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreWhat Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

How to Pursue AM Adoption Within an Established Manufacturing Organization

Succeeding with additive manufacturing requires enterprise-wide buy-in and change. EOS describes tactics including a two-team structure: transformation team and implementation team.

Read MoreThe Case for Additive Manufacturing in Production

3D printing may have started out as a rapid prototyping technique, but the machines and materials have matured to the point that production is not only viable, but desirable, in many cases.

Read MoreWhat Your CEO Needs to Know About Additive Manufacturing

Additive manufacturing promises to affect far more than manufacturing alone. When evaluating AM, the perspective needed is the view that sees the impacts all across the enterprise.

Read More

.jpg;width=70;height=70;mode=crop)