The Promise of Graphene-Based Composites for 3D Printing

A new partnership between XG Sciences and Terrafilum aims to accelerate industrial innovations using the strongest, thinnest, most electrically conductive material on Earth.

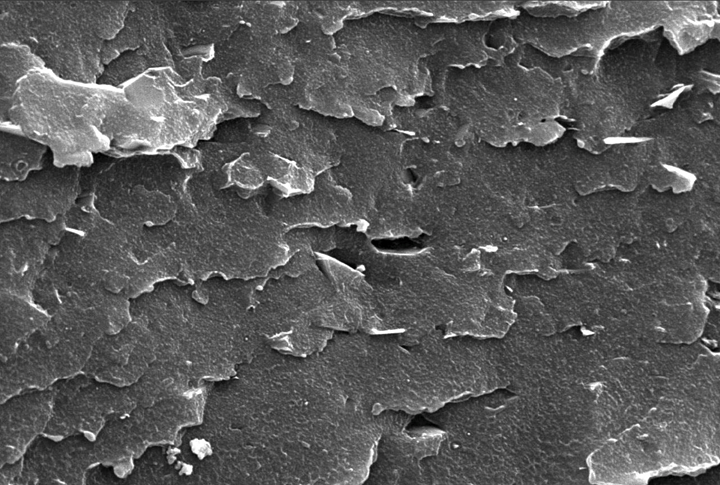

A graphene sample fractured under liquid nitrogen. New graphene-enhanced composites for 3D printing could offer capabilities for thermal conductivity and physical property improvements.

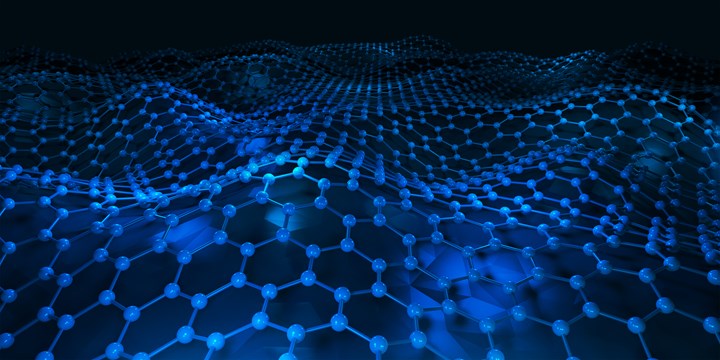

The extraordinary physical properties of graphene — a two-dimensional layer of carbon atoms arrayed in a hexagonal lattice structure — have launched stratospheric levels of speculation about its potential. Discovered by two researchers at Manchester University in 2004 (earning the pair a Nobel Prize for their efforts), graphene is many things at once: It is the strongest material known to man — 200 times stronger than steel. It is so thin — the thinnest material on Earth, in fact — that it is considered to be two-dimensional. And, due to the free flow of electrons across the lattice of carbon atoms, graphene is an unparalleled medium for the transfer of heat and electricity. Research suggests that its capacity to transfer electricity may be a thousand times that of copper, at a speed 250 times faster than an electrical charge flows through silicon.

The mind swirls, and it’s not altogether surprising that graphene has taken on a mythical status for laymen and scientists alike. The material is prophesied to revolutionize almost every industry imaginable, from semiconductors to consumer products, aerospace, energy, medicine and beyond.

Of course, science can’t keep pace with the hype. As The New Yorker pointed out in its 2014 article about graphene, material discoveries that end up being transformational, such as aluminum in the early 19th century, are sometimes researched for decades before a revolutionary application of that material (like an airplane) is even conceived.

Still, graphene can be found in dozens of consumer and tech products today, and there are high hopes for its use across several industrial subsectors. One development that could hasten industrial innovations built around graphene is already here: graphene-based composite materials for additive manufacturing (AM).

XG Sciences, a materials provider specializing in the design and manufacture of graphene nanoplatelets (small stacks of graphene) recently partnered with Terrafilum, an eco-friendly filament producer for the AM industry. In late 2019 the two companies announced a joint agreement to develop, produce and market 3D printing filaments and coatings using graphene-based materials. I recently spoke with XG Sciences chief technology officer, Dr. Leroy Magwood, who says the addition of graphene formulations into 3D-printing filaments could allow a greater variety of parts to be created at faster production rates using less energy.

An illustration of the hexagonal lattice of carbon molecules that form a layer of graphene — the strongest and thinnest material on Earth.

“If you take a plastic and you allow it to go a little further, to be a little more rigid, you now have what essentially amounts to a lightweight metal,” he says. “There are some polymers that are particularly well suited for use with graphene, to the point where, in the right systems, we can get a doubling of the base material’s stiffness, or tensile modulus.”

Magwood says that, with graphene, even a “cheap” polymer can behave like a high performing polymer or like a metal but at a fraction of the weight. “So you're going to be able to bring these things into systems and use them directly in an application without having to worry about some of the downsides of metals, including weight and cost, or the downsides of the base plastic, which is low strength and rigidity.”

In fact, the first material that XG Sciences chose to infuse with graphene was polypropylene, a lightweight, semi-rigid material that is notoriously difficult to 3D print due to the heavy warping that occurs during the cooling phase in FFF printing. A polypropylene blended with graphene, Magwood says, is much less susceptible to warping due to the thermal transport characteristics that graphene introduces to the polymer. In other words, graphene-enhanced polypropylene does not suffer from the same heat differential between layers that cause the material to warp. Magwood also says that these thermal transport characteristics also encourage better layer adhesion and a much greater Z-direction strength.

“What we find is that as long as the printer stage is heated, we're going to get really good adhesion between layers because we don't create these huge heat differentials between a layer that has already cooled down before the second layer is added,” he says. “The result is better overall mechanical properties of the material, especially in the Z direction.”

Of course, increased strength-to-weight ratios is just one of the potential benefits of graphene-based composites for 3D printing. Magwood says that it will take time to sort out market needs for these materials. Today, XG Sciences and Terrafilum are in the process of surveying potential customers before making a final decision on the specific types of graphene-enhanced filaments the companies plan to launch later this year.

Related Content

3 Unique Elements of LFAM to Consider in Design

While similar to desktop fused filament fabrication (FFF), large format additive manufacturing (LFAM) in polymer composite poses several unique challenges as a result of its scale.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

Polymer Grade Can be Used in Food Contact Applications

The polymer can be used in most fused filament fabrication (FFF) 3D printers.

Read MorePostprocessing Composite Tooling: Machining, Coating or Combination Strategy?

A project testing the surface finishing options for composite tooling reveals insight about machining and coating strategies.

Read MoreEOS North America Launches Integra P 400 Polymer AM Platform

EOS North America has launched its Integra P 400 polymer additive manufacturing platform, that accommodates a variety of materials and applications.

Read More