Rapid Tooling: Faster, Better, and Less Expensive

Don’t think of rapid tooling purely for prototyping or short runs. Additive tech is making it possible to produce steel tools that have decided benefits for injection molding and die casting.

Greg Morris, CEO/COO of Morris Technologies, a firm that specializes in an array of ways to make things rapidly, whether it is via machining or additive manufacturing, whether those things are in medical aerospace or simply something needed sooner rather than later, is a big proponent of rapid tooling technology, particularly that based on direct metal laser sintering (DMLS). He thinks that it is a potential game changer for companies that produce plastic parts, that it is something that would not only facilitate the prototyping stage, but production runs as well—and something that could readily result in higher-quality parts.

According to Morris, the creation of rapid tooling takes two forms. One has long been used. This is the process used by companies to get a tool that was capable of making a limited number of parts. The objective was to be able to have parts that could be used for prototyping purposes, not production. Although it was once the case that these tools might have had some sacrifices when it came to things like tolerances or surface finish, Morris says that technology advances in CNC, EDM and additive processes has changed that, making it possible to get closer-to-production tools. And he admits, “It is difficult to compete with CNC machining of an aluminum cavity based on the state of the technology today.” The other form of rapid tooling is based on additive processes.

This leads to a question: Just what does “rapid” mean? He says that there is a range of answers. For example, he says that there are niche companies that CNC machine simple tools for plastic injection molding in a couple days: “That’s pretty rapid. You’re not going to beat that. But they’re catering to a small segment of the total molding industry. Not everyone is going to have simple parts.” So then moving along the time line, there are those who are producing tools with EDM—sinker or wire machines. “Then a three- to four-week range would be rapid.”

But there is something in between. And this is the tech that Morris is very bullish about: direct metal laser sintering (DMLS). Here it is using the process to make the mold inserts to near-net shape within a week, then performing the final machining to achieve tolerance, which could take another week. And the resulting tools have uncommon capabilities.

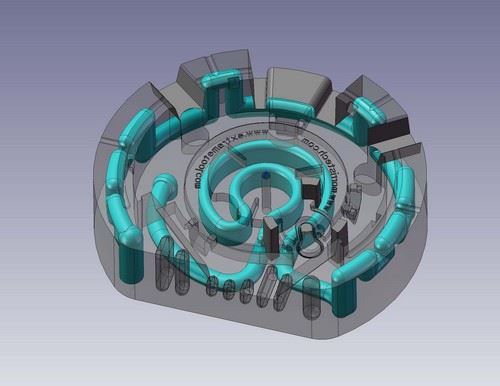

Essentially, DMLS is an additive process where layers of metal powder are sintered by a laser that moves in the X-Y axes. Each layer of powder is put down, sintered, then the platform lowers and the process continues until the object is produced. Morris says that while the layers are generally on the order of 20 microns; using EOS Maraging Steel MS1 from EOS GmbH, which was developed for the company’s EOSINT M 270 DLMS systems. The steel, which has good mechanical properties and is heat treatable to obtain high hardness (up to 50 to 54 HRC after age hardening), can be used in 40-micron layers. Consequently, Morris explains, they can actually take less time to build components with the maraging steel than stainless or other materials, yet even with the speed there is little degradation in the quality of the build. “While it is still referred to as ‘rapid tooling,’ DLMS tooling really makes sense when it begins to be used in applications that lean more toward product, because you can leverage some of the inherent advantages of the process—and that primarily means conformal cooling lines being incorporated into the inserts.”

And that, the implementation of the conformal cooling lines, is where the game can—potentially—change. According to Morris, while this approach is being taken by some European manufacturers, it has yet to take hold in the U.S. And this is something that Morris hopes to change.

Because of the additive nature of the DMLS process, there is design freedom far beyond that which can be achieved through conventional processes. For example, in the case of cooling lines, one is restricted by the shape that can generated because drills are straight. But by using DMLS, the cooling lines can be put in the inserts in any number of configurations. This, Morris suggests, can lead to potential quality and process improvements in part production. One is an improvement in the part produced. That is, there may be sections of a injection molded part that has a sink or some other area that causes problems because with conventionally produced tools it isn’t possible to get the necessary cooling (or heating) to that area. But that is not an issue with DMLS. So that is a quality advantage.

But Morris believes a more significant gain can be achieved through cycle time reduction. He says that European studies show that conformal cooling lines allow the tools to be operated faster. While the production time saves varies, “across the average there are compelling savings.”

In addition to creating tools for injection molding, Morris thinks another area where there is great promise in the area of die casting. “Typically,” he says, “die casting tooling takes a lot longer and is pretty expensive.” So there could be real gains via DMLS, assuming, of course, that these are for smaller parts, something on the order of fitting within a 6 x 6 x 4-in. work envelope. “The die casting industry, by and large, has done basically nothing with this technology, and I think it is a huge area,” particularly because of the comparatively fast speed and reduced cost with which tools can be produced.

Morris acknowledges that there is a learning curve associated with the DMLS-produced tools for injection molding and die casting. (He also notes Morris Technologies is interested in producing inserts for tooling, not to become a full-out tooling supplier.) He explains that there needs to be a different approach to tooling design in order to accommodate the DMLS components. It takes effort, time, and expense. Yet he is confident that given invests, in time there can be great benefits gained. But he also understands that there could be reticence on the part of tool makers who aren’t particularly interested in taking a risk.

Morris thinks that it may be a matter of going to the OEMs—the customers for the tools—so that they can understand the benefits that can be realized through this new approach. He points out that for big plastic processors—like Proctor & Gamble, for example—with improved cycle time, better quality product, and possibly better tool life, once the learning curve has been managed, the savings can be on the order of millions of dollars annually.

Related Content

Why This Photopolymer Developer Wants Prototyping to Go “Massless”

High-performance materials supplier polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreWhen Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More

.jpg;width=70;height=70;mode=crop)