The Hidden Complexities of Wire Arc Additive Manufacturing

Lincoln Electric Additive Solutions’ robotic metal 3D printing process is a choreographed dance between welding, robots, automation, heat management and machining. The new venture may have a distinct advantage in the field: its parent company’s 125 year-old legacy.

The excavator demonstration at the ConExpo-Con/Agg trade show in Las Vegas two years ago was nothing to write home about. Not for casual observers, who watched the machine operator aimlessly scoop and dump dry dirt like a kid in a sandbox.

But for those in the know, or for anyone who read the nearby purple banners trumpeting “The World’s First 3D-Printed Excavator,” the experience was something altogether different. And for the representatives in attendance from Lincoln Electric, the 125-year-old year old global manufacturer of welding equipment that helped 3D print the excavator’s 400-pound, 7-foot arm, the moment was bigger still.

To them, the demonstration was, they hoped, the birth of a new mainstream economic sector: large-scale robotic metal 3D printing.

Define “Large”

Robotic metal 3D printing and large format metal additive manufacturing are general descriptors of the method used to print the excavator arm. Yet these phrases leave a lot to the imagination. A more precise description? Wire arc additive manufacturing, a process that combines automated metal inert gas (MIG) welding or laser hot wire welding with direct deposition 3D printing. Picture an industrial robot arm fitted with a welding nozzle depositing bead layers of melted wire feedstock onto a multi-axis turntable, and you’ll have the general idea. It is not, as we’ll see shortly, a simple adaptation of automated welding. Not exactly.

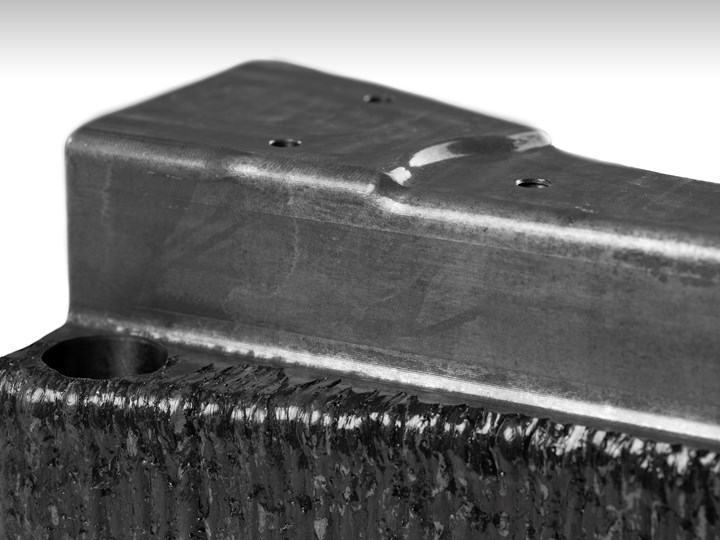

An example of a part printed via wire arc additive manufacturing. Contrast the surface finish of the bead layering process versus the finish along the top of the part.

In the two years since the Las Vegas demonstration, Lincoln Electric has poured considerable resources into wire arc AM, including a new, additive-focused business division called Lincoln Electric Additive Solutions. As the company’s business development manager Dr. Mark Douglass calls it, Lincoln Electric Additive Solutions is “a startup within a major company.”

This description feels right based on my visit to the “startup” earlier this year. Located just three miles from Lincoln Electric’s headquarters near Cleveland, the new Additive Solutions building featured six production cells that occupied roughly a quarter of the massive 75,000 square-foot space. Several additional cells have been added since my visit, with plans to fill the entire structure with up to 30 robotic 3D printing cells by 2021 — all of them printing parts and prototypes, and making repairs.

A view of one section of the new Additive Solutions facility. Behind this sits another facility that will house several additional 3D printing robotic cells.

The company’s unofficial mission statement is “Making Large Parts in Less Time,” a reference to the common pain point for industrial sectors that utilize traditionally manufactured large metal parts: costly supply-chain problems that often result from long lead times for castings or forgings.

For Lincoln Electric Additive Solutions, the key opportunity resides in the word “large” — casually defined by Mark Douglass as any part larger than a kitchen microwave. More significantly, anything larger than a part capable of being printed in a metal powder bed fusion machine.

A prime example of this is aerospace composite tooling, specifically the large, asymmetrical facesheets that often take months to manufacture. Not only do lead times for these parts depend on the availability of castings, but facesheets require complex machining setups on CNC machines large enough to handle them.

If forming shapes via melted wire feedstock sounds relatively straightforward, make no mistake: Printing a 6-foot-tall, curved steel facesheet via wire-arc additive manufacturing is a process riddled with pitfalls. And even if the nonstop eight-day-long print is successful, the resulting 300-pound monolithic part will require finish machining.

With the launch of Additive Solutions, Lincoln Electric is combining its decades-long welding expertise and innovations in automation, CNC software, and materials into a venture that utilizes all of these technologies simultaneously. Until recently, missing from the puzzle was the ability to post-process these extremely large parts — especially the ability to finish machine parts that required massive machining centers. That changed this past April — the same month Additive Solutions launched — when the company purchased Baker Industries. As readers of our sister publication Modern Machine Shop may know, Baker Industries owns and operates one of the largest machining centers in the United States.

Another example that shows the contrast between raw metal bead layering and the same material after finish machining.

A Robot Waltz

Lincoln Electric’s wire arc-additive manufacturing process is a tightly choreographed dance between the torch, the robot, the part, and a multi-axis, rotating turntable that holds the build plate. The ability to use gravity to your advantage and eliminate the need for support structures though the coordinating of these components is what Douglass calls the “holy grail” of Additive Solutions’ process: Rotate, print. Turn, tilt, rotate, print again. Repeat as long as necessary.

Suddenly there’s no need to slice the CAD strictly along the X-Y axis; it can and should be sliced along any orientation that makes sense for the part. This requires coordination of the slicing software with the robot’s automation system, as well as the ability to control a cascade of variables, including the characterization of geometric features and material properties, heat management, and a finish machining approach.

When Additive Solutions opened its doors earlier this year, these were “known unknowns.” The excavator arm demonstrated in Las Vegas in 2017 was a collaboration between Lincoln Electric, the Oak Ridge National Laboratory, America Makes, and Caterpillar — companies that worked together to develop processes and solutions as these challenges arose during the manufacture of the demo part.

A robotic 3D printing cell at the new Lincoln Electric Additive Solutions facility near Cleveland, Ohio.

Even today, Douglass characterizes Lincoln Electric Additive Solutions as part operations, part R&D shop. (It’s fair to say that this statement rings true for many companies attempting production scale with additive manufacturing.) Still, with welding at the core of Additive Solutions’ technologies, Lincoln Electric realized it had a significant head start.

Before cutting the ribbon on its new facility, consider the resources already available to Additive Solutions via its $3 billion parent company located just down the road. They include:

- Materials and feedstock: Lincoln Electric purchases raw material, draws the wire and spools it for typical welding operations. “Say we want a large volume of material because we're printing hundreds of pounds at a time,” Douglass says. “We go down the street. We buy the raw material, they draw it. Now we have stainless steel in a box and an alloy that you couldn't normally obtain in that volume.”

- Power supply: Welding relies on pulses of electric current, or waveforms, in order to manage voltage impedance and other variables. “We have experts down the street who are here all the time helping us with our waveform development,” Douglass says. “If we need a new waveform to try something differently, they can spend the day here to provide it.”

- Software: Lincoln Electric has existing robot automation software that it has modified to include CAD slicing and path planning. This software, called SculptPrint, includes proprietary features used to determine optimal deposition strategies. Which brings us to…

- Process knowledge: While the path planning and deposition strategy for wire arc additive manufacturing is more complex than processes involved with traditional welding operations, there are key crossovers. For both, materials and part geometries play a significant role in path planning, Douglass says. “Programming a zigzag pattern from right to left or left to right will have different outcomes,” he says. “Or, what if you did concentric circles? What if you did circles going from the inside out? There are myriad ways to attack how you do this.” In addition, Douglass says that Additive Solutions is developing its SculptPrint software to incorporate CNC machining code based on the CAD slicing and print path planning instructions that guide the print process. “Because the software knows what was printed, it will know what has to be removed,” he says. “It can then use that information to program the CNC and remove the material where needed. Ultimately this is what we’re working toward.”

- Machining: the Emco Mecof PowerMill at Baker Industries is a five-axis vertical machining center with a 52-by-20-by-10-foot XYZ work envelope — large enough to double as a car pad for a fleet of full-size SUVs. Even before Baker Industries acquired the PowerMill, the company had been operating a 32-foot horizontal five-axis Emco EcoMill as well as a handful of Breton five-axis machines that measure up to 27 feet along the X axis. The years of training and the incremental knowledge and experience that Baker’s engineers and machine operators have with uniquely complex setups and programming were key factors in Lincoln Electric’s decision to acquire the company.

The PowerMill at Baker Industries. The company’s experience with complex setups for large parts was a key factor in Lincoln Electric’s decision to acquire the company.

A Cycle of Abuse

During my visit to Additive Solutions earlier this summer, I saw the company’s first printed facesheet for aerospace composite tooling. The part was roughly 4 feet tall by 5 feet wide, with widths that varied from 1 inch to 2 inches from top to bottom. The part took roughly eight days to print, including stoppage time to change nozzles and allow certain areas of the part to cool between layers.

A 3D-printed “frankenpart” meant to showcase the adaptive control of Additive Solutions’ printing process, which resets and normalizes the wire arc printing path over unforeseen obstacles.

Typical operations in an automated welding cell consist of multiple short welds. Welds may last for a few minutes before they turn off, allowing the robot to reposition and begin again. The amount of time that the arc is turned on relative to the entire production cycle is only a few minutes.

“Now we have these torches and the robot and positioners and all these other peripheral components like water lines and coolant,” Douglass says. “The whole ecosystem is more than just having a laser source or an arc source and wire. And having those things turned on 100 percent of the time for days on end… The duty cycle on these things is abusive.”

Dave Sterio, director of Additive Solutions, adds that one of the biggest challenges of this technology is not only controlling thermal stress, but making sure the equipment survives the build process. “The ability of those pieces of equipment to withstand the stress of welding for hundreds of hours straight is key,” he says. “Printing the facesheet over eight days, 24/7, taught us a lot. We would go home at eight o'clock at night, come in at six in the morning and assess where we were. Over the course of that time we made numerous improvements just from monitoring that single build.”

Integrating what the Additive Solutions team learned from its initial builds into the SculptPrint software represents a large part of the work that took place during the first few months of operation. Deposition rate, bead spacing, current and voltage levels, wire feed speed, torch angle, and travel speed are interactive variables. Trial-and-error experiments with different calibrations across these variables are documented, with successful settings being continuously integrated into the system.

In a case study co-written by ORNL and Lincoln Electric researchers about the 3D-printed excavator arm, the authors discuss key challenges they encountered during the build process. Notably, they point to the types of melted beads, and the overlap between them, as being central to the success of the project and the process.

“Unlike polymer deposition, metal AM allows and requires bead-to-bead and layer-to-layer re-melting to build structures of adequate mechanical strength that are free of voids and crack initiation artifacts,” the paper reads. “A key factor is the choice of proper bead-to-bead overlap and layer heights.” Robot arm speed, wire feed rate, nominal thermal conditions, the part’s wall structure, and the average layer height were considered to be basic building blocks of printing arbitrary shapes.

Heat management is significantly important to wire arc AM technologies. Inter-pass temperatures for steel are optimally controlled at 300°C, with higher temperatures resulting in overhang features, and lower temperatures producing brittleness, poor bead-to-bead remelting and voids within the part. The arc process, output voltage and current from the power supply — notably, all areas of expertise contained within Additive Solutions’ parent company — are key variables for success. This is why Douglass and many others at the company are so optimistic about the future.

“I don't see anybody else in this industry that has that amount of knowledge and control over all the bits and pieces necessary to get additive to work,” Douglass says. “Are we machine builders? Yes. Are we feedstock manufacturers? Yes. We have a proprietary software and decades of process knowledge. And with Baker Industries we have machining and part assembly capabilities. You can see the world is moving towards the 3D manufacturing, and everything points to the fact that we should be in this business. So let's do it.”