Machine Shop Finds Opportunities with SLA 3D Printer

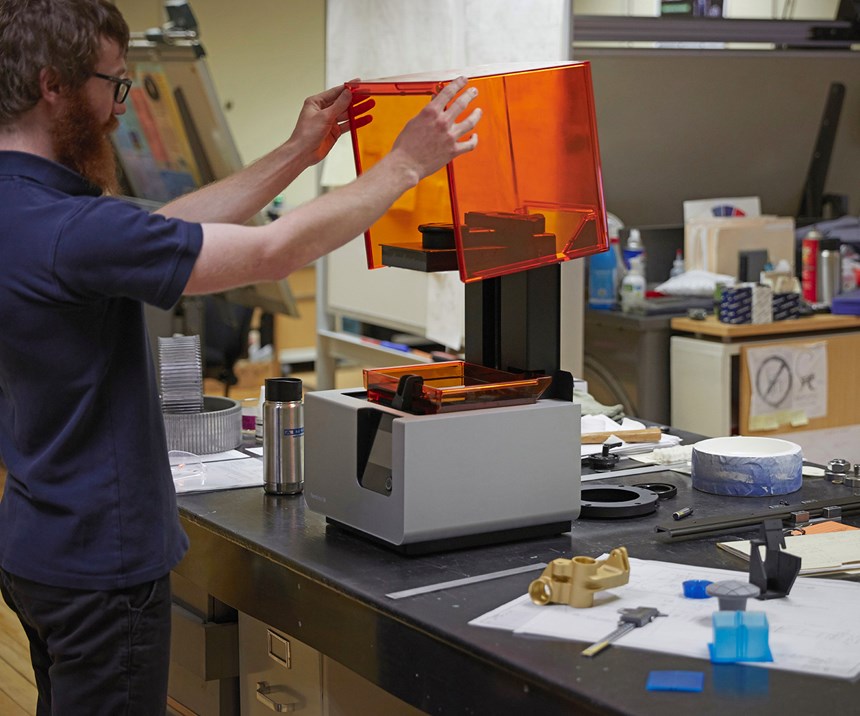

Adding a Form 2 desktop stereolithography 3D printer from Formlabs has enabled A&M Tool and Design to expedite workflows with 3D-printed prototypes, tooling and more.

Speed has always been linked with success for production environments. Adding new tools has the potential to increase efficiency, but in an ever-changing technology landscape, it is a challenge for manufacturers and machine shops to choose tech that is both reliable and cost-effective. With these requirements in mind, A&M Tool and Design recently added a polymer 3D printer to its toolset. Offering a precise, fast means of making prototypes and other parts, this 3D printer has helped to expedite workflows and increase the shop’s capacity for affordably producing parts in-house.

Toward Efficiency and Precision

Established in 1948, A&M Tool and Design started as a family-owned, single-source precision machine shop in Southbridge, Massachusetts. Today that description still holds, but of course looks a bit different; alongside highly-skilled operators running classic Bridgeport CNC mills stand eight-sided tombstones for a Mazak Palletech system that can run unattended 24/7.

The shop has modernized over the years to introduce a range of new equipment in addition to reliable traditional technology and retrofitted solutions to produce parts and custom machines for aerospace, optics, and robotics. Customers include Boston Dynamics, LinkNYC, NASA, Goodrich and Corning.

In addition to large-scale manufacturing automation equipment like the Palletech, last year the shop added an industrial-grade desktop stereolithography (SLA) 3D printer to expedite projects and open capacity to supplement an understaffed engineering team. In order to effectively replace prototyping that would otherwise be done through more labor-intensive processes or workflows, the 3D printer had to be both cost-effective and precise. Ryan Little, an A&M Tool mechanical engineer, researched which 3D printer would best match for the company’s needs, and selected the Form 2, a desktop 3D printer from Formlabs.

“Part of our pursuit in looking for a 3D printer was being able to have something that could run pretty autonomously with limited training,” Little says. “We can run some of the CNC machines downstairs, but they're rarely available, and programming a CNC machine for an advanced job in Mastercam, or just trying to do it on the controller itself, can take hours. Starting up a job with Formlabs PreForm software takes 10 minutes, and it's really simple.”

“It’s kind of a cliché, but it’s really allowing all of us to think completely outside the box.”

The company has since scaled 3D printing applications from prototyping and communications models to quick-turn production tools and end-use parts for custom machinery.

“3D printing has become a priceless tool in our toolbox,” says Guido Jacques, vice president of operations at A&M. “It’s kind of a cliché, but it’s really allowing all of us to think completely outside the box.”

3D Printing Opportunities

Little and team are constantly finding opportunities to leverage cost-effective 3D-printed plastic parts to enhance workflows and projects. The shop has come to rely on the printer to mitigate errors and accelerate timelines from pre-production prototyping, to creating production tools to printing end-use parts for quick fixes.

Does this part need to be metal? Can a polymer-based material be an easy substitute?

In many cases, it’s a materials-led decision: Does this part need to be metal? Can a polymer-based material be an easy substitute?

“There are plenty of things that our engineers can go turn on a lathe,” Little says. “We can whip out a very specific diameter shaft in 20 minutes, and it'll be very accurate. But if it's something that it would take a machinist five hours to program and 10 hours to make, we can choose 3D printing over machining. It's very similar to the machining world, where you could probably make this out of aluminum. It doesn't need to be titanium.”

Accelerating Prototyping

For prototyping, the shop started using 3D prints to test fit and function. 3D printing allows the engineering team to make parts much faster and utilize all hours of the day, setting up prints to run overnight then using parts the next day. Printing is especially helpful for geometries that are costly and time consuming to produce on a CNC machine.

“The printer almost feels like an auxiliary tool in addition to CAD,” Little says. “We do a ton of prototyping for different types of tooling. If we didn’t have the Form 2, many prototypes would just stay in CAD until we were ready to machine, and there would be some things that would never get made or designed because it wouldn't be practical.”

Improving Communication

The A&M engineering team also uses 3D prints to help communicate with machinists and welders, turning complex drawings into physical models. Increasingly, the machinists themselves are making requests for models.

“Sometimes we'll see a finished part and realize a hole was tapped in the wrong direction, or a feature wasn't supposed to be on a certain side–and that's not something you can fix. When that happens, the part is pretty much finished, and you have to restart,” Little says.

“We have talented machinists here who can interpret drawings with so many call-outs on them that you almost can't see what's happening, but even still machinists will have to ask for clarity, especially when there are more complex geometries like undercuts. Now, if we have an assembly or SolidWorks file, we'll make a scale model of the part and give it to them, and they love that. The whole shop is actually starting to draw on it.”

In-House Jigs and Fixtures and 3D-Printed End-Use Parts

Beyond prototyping, the A&M team has scaled to use 3D printing to produce functional parts like fixtures and even several end-use parts, from an ergonomic knob for a custom-built machine to a coupling used for a short-term fix for one of its large lens polishing machines.

For example, when a spider coupling for the lens polishing machine arrived in the wrong size two days before a big trade show, Little quickly designed and 3D printed a correctly sized replacement in Formlabs’ Durable Resin. The printed coupling was used to drive a two-horsepower motor on a grinding machine.

Ongoing Applications for 3D Printing

A&M Tool introduced one 3D printer less than a year ago and continue to find valuable new applications and experiment with new materials.

“3D printing allows us to do a lot of things that the shop can't easily do—geometries for making parts that would be a nightmare on a machine, etc.,” Little says. “It's given a shop a real advantage.”

“It will justify itself with helping you do things that your customers aren't thinking about at the time of purchase. We’ve been very happy with the Form 2, and very happy with the decision that we've made,” Jacques says.

About the Author

Andrew Edman

Andrew Edman is an applications engineer at Formlabs focused on using additive technologies to create value in manufacturing and industrial workflows, like using 3D printed tooling to bridge from prototype to production.

Prior to Formlabs, Andrew ran a design and engineering consultancy, helping startups and Fortune 500 companies develop products from concept through to scale manufacturing.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Machine Shop Turns to Additive for In-House Safety Covers and More

After purchasing a 3D printer to solve a safety issue, turning shop Swiss Automation has found many more applications for the additive manufacturing technology on its shop floor.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More