Lightweight Components: A Paradox When Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

Share

Read Next

As I discussed last month, the “free complexity” of AM is often touted as the main advantage compared to more traditional manufacturing methods. The ability to make lightweight, bio-inspired shapes or lattice structures with AM is frequently heralded as the reason to switch. But what if those organic-looking parts could just as easily be made by conventional means? Granted, there are certainly some shapes that can only be made with AM, but what if the design guidelines for machinability, tool accessibility and fixturing could be captured for a machining process, say, and used in a computer algorithm that was designed to generate lightweight parts? If so, then the generative design software tools creating buzz with AM could just as easily help machining.

Before we dive deeper into that, you are probably wondering how a computer algorithm can generate lightweight parts on its own. Turns out, it is easier than you think, and those computer algorithms, traditionally referred to as topology optimization, have been around for about as much time as AM has been in the market.

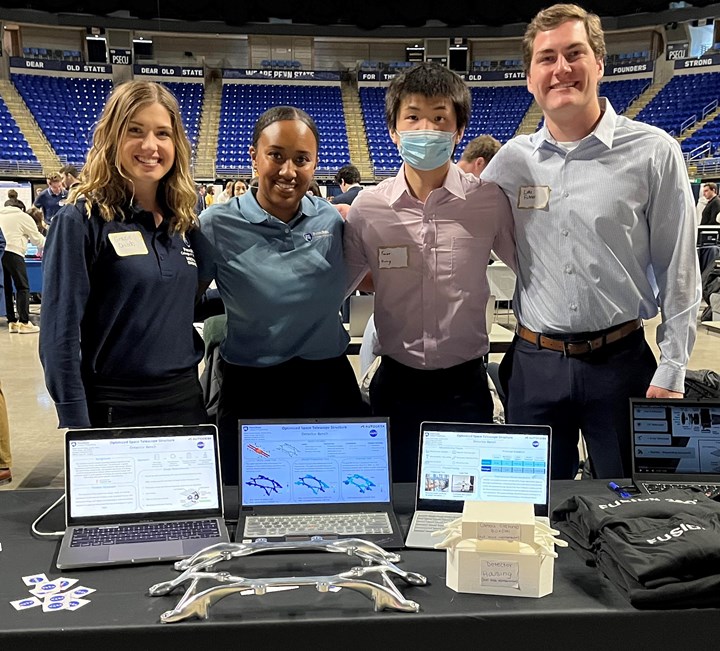

Penn State engineering students, left to right, Gracie Chiodo, Jennifer Aklilu, Yanen Huang and Luke Fichner used Autodesk Fusion 360 to generate a lightweight structure for their NASA capstone design project (sponsor: Ryan McClelland, NASA; Faculty Advisor: Sanaz Takaghaj, Penn State) that was easily machined by Protolabs in less than a day. Photo Credit: Gregg Stoklosa, Autodesk

At its most basic, topology optimization uses mathematical algorithms to lightweight structures by removing material from a 3D solid model in regions where there is little to no loading, or forces and torques. It is most often applied for structural analysis, but algorithms have also been developed for fluid flow, heat transfer and pretty much any physical phenomena that can be discretized, modeled and analyzed on a computer.

With topology optimization, the user specifies the bounding box and “keep out” zones that limit where material can be added, the loading on the component and any of its mating interfaces, and any additional constraints that restrict movement or ensure connectivity to other parts. This is most often done by the design engineer or structural analyst, but manufacturing and process engineers can use topology optimization to design lightweight fixtures just as easily.

Once the loading, constraints and volumetric boundaries are specified, a topology optimization algorithm is used to remove material from the existing component to reduce its weight. Material can also be added back by the algorithm to ensure that the part does not fail, deflect too much or fall below a given factor of safety when trying to achieve a targeted weight reduction.

The application of topology optimization to fluid flow, heat transfer and other types of problems follows the same basic setup, replacing structural criteria with relevant performance indicators, such as pressure, drag or thermal efficiency. The discretization, computational power and fidelity of analysis (that is, linear, nonlinear) drive the accuracy of the results and the cost and time to obtain them.

The challenge with topology optimization has always been the ability to fabricate the lightweight result with traditional manufacturing methods given the intricate shapes that often result. This is why topology optimization and AM go hand-in-hand: AM is usually the easiest way to fabricate a topology-optimized component, layering material only where it is needed.Obviously, there are many caveats to that and often many challenges when making topology-optimized parts with AM, such as support structures, but topology optimization has enjoyed renewed interest in the past decade just like AM — another overnight success that was 30 years in the making.

There are no layering effects on a subtractive part, but there will be other telltale signs when machining. Photo Credit: Timothy Simpson, Penn State

What is interesting about most traditional topology optimization algorithms is that they generate parts by subtracting material away from the original structure. Most algorithms start with the existing component and then slowly remove material away from low stress regions until a certain amount of material has been eliminated or one or more deflection or failure criteria become active. So, we have computer algorithms that subtract material away from a part to design a version that is best made using AM.

Many others have realized this, and we are now seeing a slew of new computer algorithms and approaches for generating lightweight structures.Some add, some subtract and others do both. Some use artificial intelligence and machining learning algorithms to generate intricate structures and lightweight components, while others mimic the growth of slime molds, plant seeds rising toward the sun and so on.

Mother Nature has been generating evolving organisms, structures and life for millennia; so, why not look to nature for inspiration when generating new designs? In doing so, why not “program” those algorithms to take into consideration the various constraints of what can (and can’t) be made with a specific type of manufacturing process so that designs evolve and develop into something that can just as easily be made by machining, casting or other traditional methods as it can with AM?

Unfortunately, this creates a paradox for machining, since the lightweight component will often take longer to machine, increasing cost and waste.Could newer algorithms help us solve this machining paradox? The computing power is no longer limiting us; so, why should we limit ourselves to optimizing lightweight parts that can be made with AM?

Related Content

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreDecentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

Read MoreHybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More