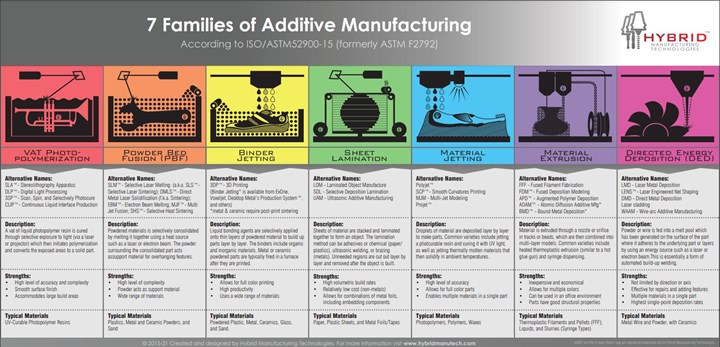

Infographic: The Seven Families of Additive Manufacturing Technologies

An infographic from Hybrid Manufacturing Technologies offers a quick overview of the seven “families” of additive manufacturing.

Share

Infographic courtesy of Hybrid Manufacturing Technologies. Click here to download a printable copy.

Editor’s note: Hybrid Manufacturing Technologies updates this graphic on a yearly basis. The most recent can always be found in the Resources section of the company’s website.

In the mainstream media, “3D printing” has become a shortcut way of describing all additive manufacturing technologies. It’s problematic, though, because it tends to conjure an image of just one type of 3D printing—the desktop style many people may have seen in their local library or child’s classroom. But AM is much more than plastic extrusion; there are so many technologies that can be considered “additive” that it can be difficult to keep them straight even if you’re familiar with them, let alone explain the differences to friends, colleagues or customers who aren’t.

This infographic produced by Hybrid Manufacturing Technologies delineates the distinct characteristics of each of the seven according to ASTM F2792 standards (“hybrid” technologies such as the company’s Ambit printhead that integrate AM with other processes might be considered an eighth category). While not meant to be comprehensive, this graphic could be a helpful aid for visitors, students or customers who need a fast overview of the technology differences.

Click here or visit Hybrid Manufacturing’s Resources page to download a printer-friendly PDF of this infographic.

Related Content

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

.jpg;width=70;height=70;mode=crop)