When I first visited technology developer and parts producer 3DEO back in 2018, co-founder Matt Petros summarized the company’s strategy to commercialize its metal additive manufacturing process in these terms: Nail it, then scale it.

Matt Petros says that 3DEO has moved away from transactional 3D printing focused on delivering parts, toward a more holistic approach centered on partnering with customers to solve larger problems with the company’s Intelligent Layering 3D printing technique.

Six years later, the Torrance, California, company has come very close to nailing its 3D printing method (a hybrid sinter-based technique similar, but not identical, to binder jetting) and is now turning its attention much more toward scale. It has expanded its capacity from the handful of Beta machines I saw on that first site visit, and now has around 20 of its “Saffron” production machines in operation, as well as a larger building and a much bigger team.

20 Saffron 3D printers are currently in operation at the Torrance, California, facility but there is ample floor space to add more in the future.

But alongside this upward trajectory has come a fundamental shift in the company’s business strategy. Where previously the goal was to capture production work for small metal parts that might previously have been made through machining or metal injection molding (MIM), 3DEO has turned away from piecemeal part production in favor of integrated projects where 3D printing can provide multiple, more holistic benefits.

“That gets us out of many commodity products,” Petros says, “but allows for concentration.” That concentration is necessary, 3DEO has found, in order to focus on the applications where its technology makes the most sense and where scale is possible.

Intelligent Layering and Beyond

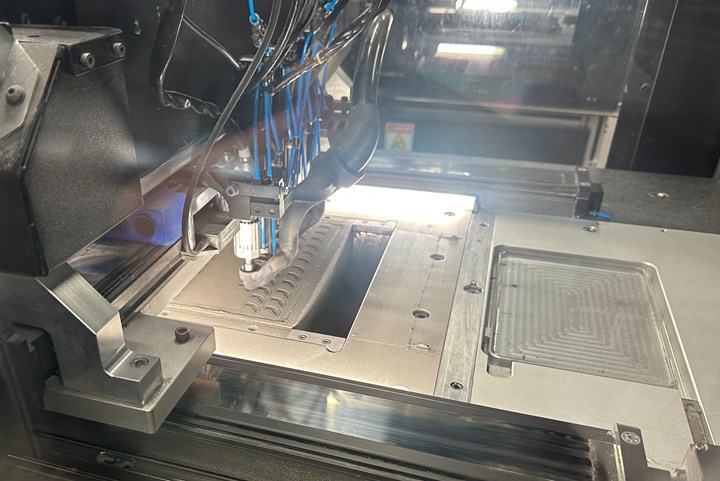

3DEO’s proprietary additive manufacturing process is called Intelligent Layering, and involves a hybrid of material layering and milling. The printer spreads a layer of MIM powder (which is finer than powders typically used for 3D printing processes like binder jetting and laser powder bed fusion) and then sprays its surface evenly with a thin coating of binder temporarily gluing the entire layer together.

Intelligent Layering uses a binder jetting-like process that deposits layers of metal powders that are then sprayed with binder. Part geometry is created with a cutting head carrying eight milling tools that can operate independently or in tandem.

After one or multiple have built up, a machining head mills the geometry for that portion of the part into the material. The head carries eight cutting tools which typically operate simultaneously to mill eight parts at once, but can also be controlled independently. In addition to creating the geometry of the part, the milling step enables smoother surfaces and finer features, including those internal to the part.

At the end of an Intelligent Layering build, all the printed material has been coated with binder. Parts shaped via the milling heads are embedded inside the unused material and must be broken out.

The final build emerges from the printer as a cake of material. Parts are broken out from the cake and depowdered by hand or with automation. The green metal parts are then sintered in a furnace to become fully solid.

But perhaps the most significant way that the company is pursuing scale production currently comes in its pointed approach to design for additive manufacturing (DFAM).

Sintering is needed for parts made via Intelligent Layering to achieve their final density and material properties. For many parts the workflow might stop here, but 3DEO has recently added capacity for assembly, machining and even testing to provide a wider range of services to customers.

In mid-2022, Petros says the company made an intentional choice to emphasize its design services and expertise. DFAM had always been a part of the process for working with customer parts, of course, but the company began to market this capability and even offer technology-agnostic design courses. Perhaps the biggest shift, however, is in its DFAM-heavy approach to customers and new projects.

“We no longer print parts not designed for additive manufacturing,” Petros says.

Rather than focus efforts on recreating parts originally designed for conventional processes, the company is now seeking clients and opportunities where additive can do more — provide consolidation, improve performance, reduce manufacturing complexity, or bring other benefits beyond speed or cost compared to MIM, casting, forging or machining.

3D Printing as a Partnership

Seeking out these DFAM (and by extension, AM) opportunities is messy, Petros acknowledges. The company has even parted ways with some existing customers as a result of this focus. That’s ok, he says, because 3DEO today is more about partnerships.

“We’re not just printing to get the transaction,” he says. “We want a true partnership. We’re not going after thousands of customers. We’re going after dozens.”

Aiming toward those partnerships is making it possible for 3DEO to focus less on how to make individual parts, and more on how to solve larger problems. Now, initial conversations with clients tend to include a bigger exploration of the part’s purpose, its role within the product, the other components it interfaces with, and how DFAM and 3D printing can be a solution for multiple challenges at once.

“We have to ask lots of annoying questions,” he says, “but you can’t take advantage of additive if you can’t play in the entire sandbox.” By defining the potential boundaries of that sandbox early on, 3DEO is better able to get at the ways that additive can bring the greatest value to the application. Some examples of this principle in action are outlined below:

Rail Fastener

These two 3D printed parts (together with two off-the-shelf spring washers) replace the 14 different parts that were previously assembled together to produce one gangway fastener for the Shinkansen bullet train.

The gangway fastener pictured here is used on Japan’s Shinkansen bullet train, where it sits inside a U channel to connect the cars. Each such connection requires 18 of these assemblies. For years gangway fasteners have been produced by assembling 14 different parts in a process that includes four riveted joints, manually drilled holes and a great deal of human touch.

The previous version of the fastener required a total of 14 parts and processes including manual drilling and riveting. Rather than evaluating the assembly looking for 3D printing candidates, 3DEO reimagined the entire component with the customer.

Today, the gangway fastener is just four parts: two 3D printed pieces that 3DEO produces, and two off-the-shelf spring washers. The change has allowed for reduced reliance on forging for the customer, as well as easier installation and replacement for these parts.

“Previously, we would have looked at something like this and tried to pick out the parts that we could 3D print with little or no design change,” Petros says. But by considering the role of this component and the full process to produce it, 3DEO arrived at a better solution for both the customer and the application, using 3D printing in a targeted fashion.

Aerospace Latch

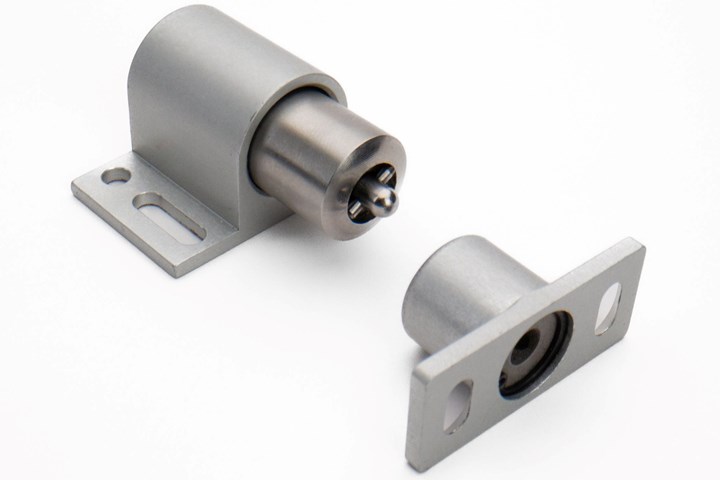

In another recent use case, 3DEO took over production of a latching mechanism for an aerospace application. The assembly includes two parts that were previously investment cast, polished and coated with Teflon. In the course of redesigning the part for AM, 3DEO began to question whether the surface finish and coating steps were necessary.

Redesigning these components of the latch’s locking mechanism for AM allowed the customer to eliminate the polishing and Teflon coating steps necessary when they were sourced through investment casting.

With geometry modifications, the company was able to achieve a working design produced with Intelligent Layering that no longer requires these extra processing steps; although 3D printing the parts costs more than casting them, avoiding these extra operations offsets the cost difference. The change in manufacturing method also avoids challenges with the aging investment casting supply chain and simplifies sourcing for the customer. The first latch components of the new design were developed and produced within just 3.5 weeks.

Custom Fitting

3DEO was working on a subassembly when it discovered the additive opportunity for this connected fitting. The customer was sourcing three expensive fittings, sawing them in half, and welding them together to create the geometries that they needed. 3DEO was able to consolidate that expensive process into just one 3D printed part, and now delivers the full assembly. The customer now also benefits from the ability to easily customize at scale.

This 3D printed fitting replaces a complex assembly that was previously created by sawing apart and then welding together off-the-shelf components.

Looking Forward With Intelligent Layering

Intelligent Layering is the foundation of the 3DEO business, and since its beginning the company has developed and operated its 3D printers internally, opting to be a parts producer rather than a machine supplier. That could change soon, as the latest iteration of the company’s Saffron printer to apply Intelligent Layering has been developed and designed with potential external users in mind, with touches like sleek enclosures and vertically opening doors for easier maintenance and access to the build chamber.

Internal lab capabilities have enabled 3DEO to expand its product offerings based on customer demand.

But even if and when Saffron systems begin shipping to customers, 3DEO is still invested in producing metal parts at scale in its Torrance, California, facility, maybe more so than it has ever been. The company has taken on assembly work and even some light post-machining to add more value to parts it produces.

Software development and integration has become increasingly important at 3DEO. The company uses ERP and MES software it developed as well as various monitoring technologies to keep an eye on what’s happening within each build.

Workflows are managed by an ERP/MES system developed internally to integrate with the peculiarities of the proprietary additive manufacturing process. It has added material development capabilities, recently adding 316 and 304L stainless steels and copper to its 3D printing portfolio alongside the 17-4 it has used since the beginning.

Many parts are still depowdered by hand at 3DEO, though the company is working to automate this as well as various other steps in the AM workflow.

3DEO is also working to automate various steps in the Intelligent Layering workflow such as breakout and depowdering. It is refining a vision system for identifying and counting parts that will soon be integrated for pick-and-place part handling. The company has even gone as far as developing a stylus-style teach pendant that allows an operator to more easily program a robot arm to handle the delicate green parts with as much finesse as a human hand.

All of these efforts contribute to the partnership role that 3DEO aims to play; by providing more services onsite and becoming more productive itself, the company can pass along savings and efficiencies to its customers. While literal cost per part might not always come out lower than a conventional option, 3DEO looks holistically at performance improvements, speed and logistical savings, such as reducing the number of individual parts that must be tracked and managed.

“Just making parts doesn’t add value,” Petros says. “We don’t want to race to the bottom. We want to transition metal parts and solutions into production.”

Related Content

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreRead Next

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read More3DEO’s Strategy to Perfect and Scale Metal AM

With a fast, flexible and increasingly automated process for metal additive manufacturing, 3DEO believes it’s cracking the code for volume production.

Read More3DEO Adds Design for Additive Manufacturing as Core Service

IMTS 2022: New offering opens 3DEO’s technology to customers across all stages of product development.

Read More

.jpg;width=70;height=70;mode=crop)