Formnext Sparks AM Surge: Insights for IMTS 2024 and Beyond

Formnext events are helping the additive manufacturing industry set a course for a more productive, sustainable industrial future with pioneering AM technologies.

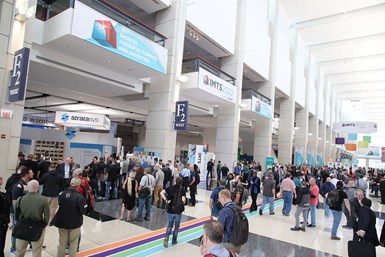

The growth witnessed at Formnext 2023 serves as a compelling indicator for the additive manufacturing (AM) industry’s continued expansion. The symbiotic relationship between startups, investment influx and regional economic development organizations was evident at the trade show, with exhibitor groups that have played a pivotal role in catalyzing industry growth. Incubators like these not only offer resources and support for entrepreneurial endeavors but also facilitate the emergence of new ideas. This trend is anticipated to be reflected in upcoming events such as at the Additive Manufacturing Sector, accelerated by Formnext, at IMTS 2024, Sept. 9-14, and Formnext Chicago, April 8-10, 2025.

Startups, fueled by venture funding, play a crucial role in driving AM’s trajectory. Formnext’s annual Startup Challenge, featuring a diverse array of companies, serves as a litmus test for the industry’s vitality. Investment in additive ventures continues to surge, while mergers and acquisitions maintain a steady pace, underscoring sustained market growth, which consistently expands annually by double digits.

Examining Formnext’s trajectory offers insights into the industry’s health and momentum. The event’s growth is impressive — experiencing a 41% increase in exhibitors and an 84% rise in visitors from 2021 to 2023. Concurrently, floor space has expanded significantly, witnessing a 42% increase, reaching more than 54,000 square meters in 2023. This rise reflects the escalating interest and investment in AM technologies worldwide.

As attention shifts toward IMTS 2024, AM continues to be an emerging technology focal point, underscoring its significance in the broader manufacturing landscape. IMTS, the cornerstone event in manufacturing technology, will showcase AM technologies in its AM Sector, accelerated by Formnext, and continue to solidify their status as a complement to the existing tools available to the manufacturing sector. The convergence of industry giants, startups and attendees at IMTS promises to ignite discussions, collaborations and innovations that will push North American manufacturing forward.

In the dynamic landscape of AM, events like IMTS and Formnext serve as barometers of industry trends and trajectories. Their increasing prominence mirrors the escalating demand for new solutions. AMT — The Association For Manufacturing Technology (the owner and operator of IMTS — The International Manufacturing Technology Show) is bringing new excitement to IMTS 2024 and North America through its partnership with the European trade show producer Mesago Messe Frankfurt GmbH (the producers of Formnext) and Gardner Business Media (GBM).

By combining the Formnext brand, history and strength with AMT and GBM, Formnext in the USA delivers the essential elements that support the North American manufacturing community’s investment in AM technology. Together, they expand the

opportunities AM brings to the manufacturing industry as Formnext focuses on the efficient realization of parts and products, from their design to serial production. U.S. events include:

- Additive Manufacturing Sector, accelerated by Formnext, at IMTS 2024

Sept. 9-14, McCormick Place, Chicago, Ill.

- Formnext Chicago

April 8-10, 2025, McCormick Place, Chicago, Ill.

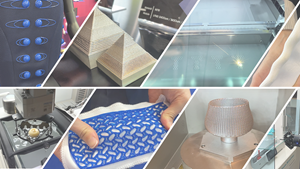

As AM continues to permeate various end markets, from aerospace to health care, its transformative potential becomes increasingly evident. With each edition of Formnext and IMTS, the industry reaffirms its commitment to pushing boundaries, shaping the future of manufacturing and driving global economic growth.

Related Content

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreMeet The Cool Parts Showcase Winners

The Cool Parts Showcase winners for 2023 were announced at Formnext Forum Austin. Watch the award presentation here.

Read MoreFinland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More