New material developments for additive manufacturing (AM) often arrive as "like" alternatives to more commonly used conventional ones. But Chromatic 3D Materials takes a different approach in its development of flexible, rubber-like thermoset polymers for 3D printing. Rather than fitting the material to a particular print method (thereby changing the material), Chromatic approaches the problem by working backward from the desired end chemistry. "We take the material and make it printable," says Cora Leibig, who founded the company in 2016.

Today Chromatic formulates, produces, develops applications for, and 3D prints with these flexible thermoset plastics, working out of its Golden Valley, Minnesota, headquarters as well as a subsidiary in Germany. Its two-part FlexTune polyurethanes are pumped to an extrusion-style print head mixed at the nozzle, and cured rapidly at room temperature. The company's specialty is flexible but tough materials in the range of 50 to 90 Shore A, a category of polymers that Leibig perceived as a blind spot when she started the business. "I saw that this class of materials was missing from additive manufacturing," she says, "and I knew how to change the chemistry to make it work."

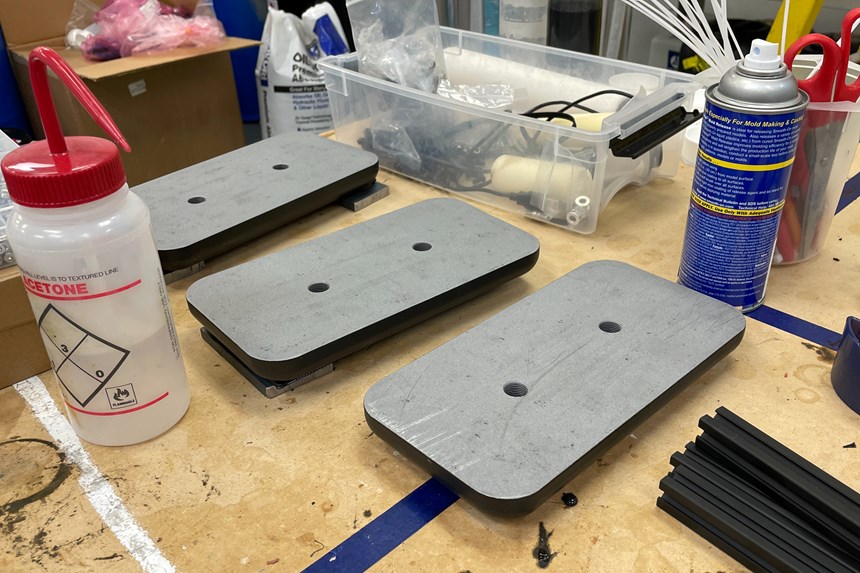

Cora Leibig founded Chromatic 3D Materials to fill the need for durable and flexible polymers for additive manufacturing. In addition to new material development, the company also prints standalone parts and adds material to other substrates; the component shown here combines a steel base with a 3D printed polyurethane tread.

Importantly, when Leibig talks about changing chemistry, she does not mean that a final 3D printed part will be fundamentally different from a conventionally injection molded counterpart. On the contrary, their chemistry will be identical at that stage. What is different — and why specialized 3D printing chemistry is needed — is the starting formulation, which might include chemical additives or other alterations needed for printability. "The end result is the same, but the way we get there can be quite different," Leibig says. Much of Chromatic’s work today is creating those equivalent resins which can be 3D printed and cured into polymer materials matching what is expected from molding.

More Than Material Formulation

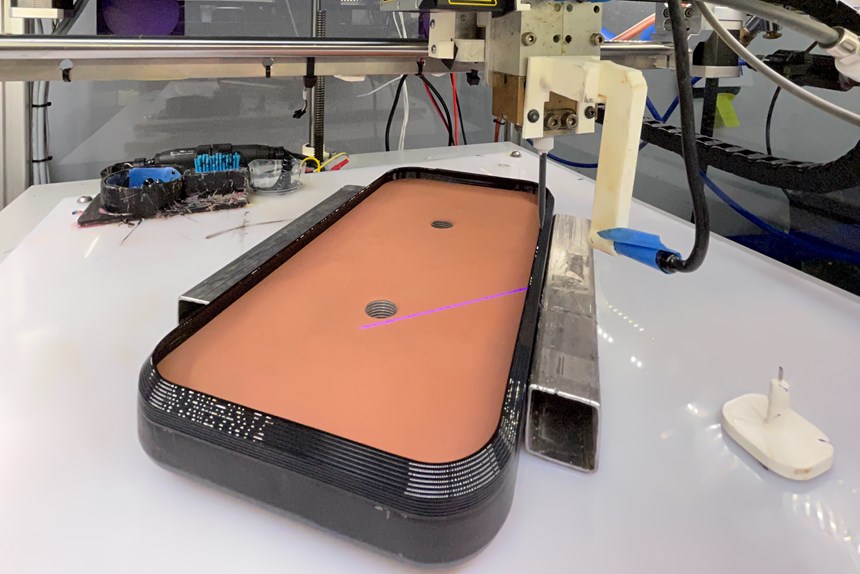

Chromatic 3D Material’s two-part polyurethanes are mixed at the printer nozzle and deposited; the reaction allows the printer to move faster than one fed by filament that must be melted to fuse.

But material chemistry is only one part of Chromatic 3D Material’s activities. To advance these 3D printable resins into end-use and serial production additive manufacturing has demanded a more holistic view. Alongside material formulations, Leibig and her team have also had to develop modifications to allow commercially available extrusion-style printers to deposit these viscous materials. They have had to create software that manipulates print paths differently. As these materials advance into applications and physically move into customer facilities, Chromatic is also heavily involved in developing parts for production and setting those customers up for success if and when they bring the manufacturing in-house.

The 3D printing method used is called "reactive deposition." The process is compatible with many gantry-style 3D printers, so long as they can support the weight of the material delivery system at the print head. (At Chromatic HQ, production is performed on 3D printers from Juggerbot, InnovatiQ and Industrio — but the company is in ongoing talks and collaborations with various printer manufacturers interested in this integration.) Tanks mounted outside the machine feed the two-part resins into the nozzle, where the materials are mixed to initiate the reaction before they are extruded onto the build. The process takes place at room temperature and the polymer cures without the aid of UV light or any other input. The deposited material is just flowable enough that infill lines can merge together leaving no gaps, and that layers fuse together at 100% density according to the company. Right off the printer, parts are watertight and even capable of holding vacuum.

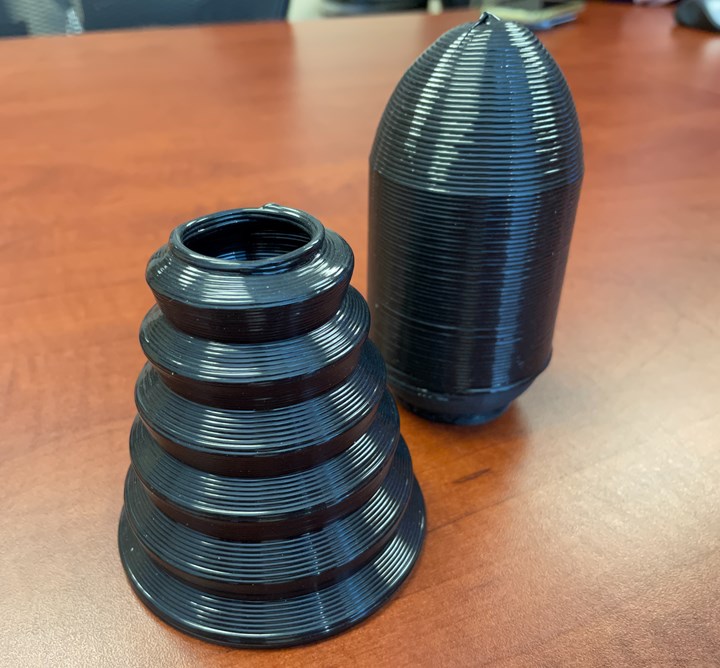

The 3D printing mechanism here might seem to be a concession to the material, a modification that was needed because of the resin's viscous nature. But it is actually an advantage. Because the material is liquid and can be driven by a pump, the deposition rate for these resins can be much faster than standard fused filament fabrication (FFF); the bellows shown below was printed in just 45 minutes for instance. The polyurethane material remains somewhat soft for 20 minutes or so after printing (so deformation must be avoided during that time) but after this period, no further finishing or postprocessing is necessary unless the specific application requires it.

This bellows and scaled-down bladder for a hydraulics system showcase the types of parts where Chromatic's material and process shine. Parts like this today are molded in a process that produces a seam, which is frequently a fail point. The 3D printed version has no such fail point, bringing an advantage over the conventional method versus just equivalency.

The flowability of the resin makes a difference in flat parts like this gasket; each deposition path can flow into the others in its layer, avoiding gaps.

In addition to its speed, reactive deposition also requires different thinking about toolpaths versus FFF and Chromatic 3D Materials is actually developing specialized software to adapt the printer’s movements and operations to best deposit the material. Filament extrusion paths are not necessarily aimed at achieving 100% infill, Leibig says, and conventional toolpathing software often results in gaps at corners and other features. But Chromatic’s viscous resin materials can flow into corners and fill those gaps. The material can also enable different deposition strategies like higher flow for printing layer borders without changing the Z height, and overhangs exceeding 60 degrees.

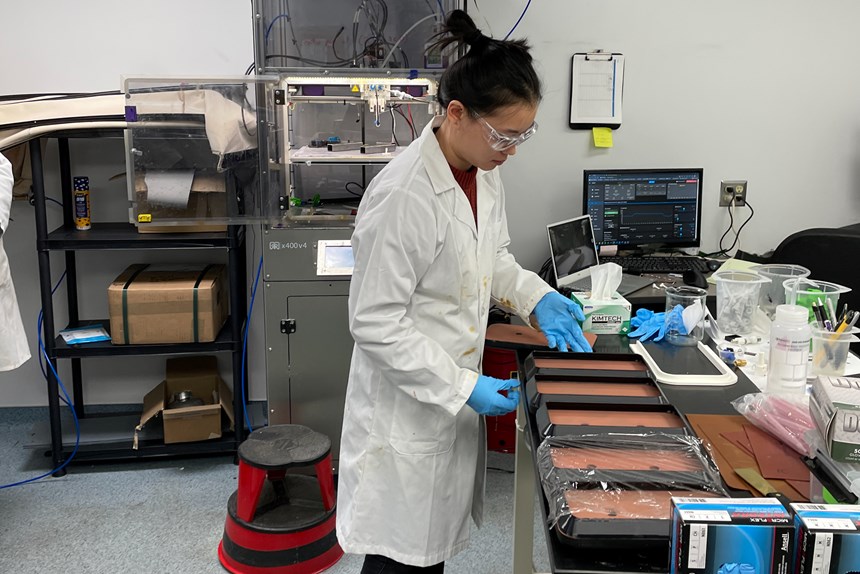

All these advances are already being used in service of real-world applications. The company is working with a number of customers to not only create custom formulations in some cases, but also to dial in the design and print parameters for the application. When a part number or product is fully developed, Chromatic intends to hand most production off to customers.

But for now a high percentage of additive manufacturing production being done with Chromatic 3D materials is taking place at the company’s Minnesota headquarters. Much of this is spare and replacements parts, commonly items such as gaskets and seals, bellows, and hydraulic bladders pictured above. These are cases where quantities needed are low, conventional parts or the molds to make them are not accessible, and/or the manufacturing of the parts presents some difficulty. One of the parts the company was working on during my visit was a five-foot long fender for a tractor needed in quantities of only about 30 per month. Aside from requiring expensive tooling, this long, flat part is difficult to make with injection molding because of the need to flow the material across its entire area; 3D printing, however, easily delivers material everywhere it is needed.

Injection molding a large part like this tractor fender would require a large tool (and all the lead time and cost associated with this) as well as a specialty molder to produce it. With 3D printing each part can be made in about 4 hours, with no need to wait for tooling or to justify its cost.

Flexible Materials for Flexible Fabrication

The gap articulated at the company’s founding — the need for durable, flexible thermoset polymers in additive manufacturing — is actively being filled at Chromatic. However, some of the most promising applications for these materials are those where they might be used in combination with other substrates or in a gradient; capabilities for printing graded materials have already been demonstrated and will be available for customer trials later in 2022, Leibig says.

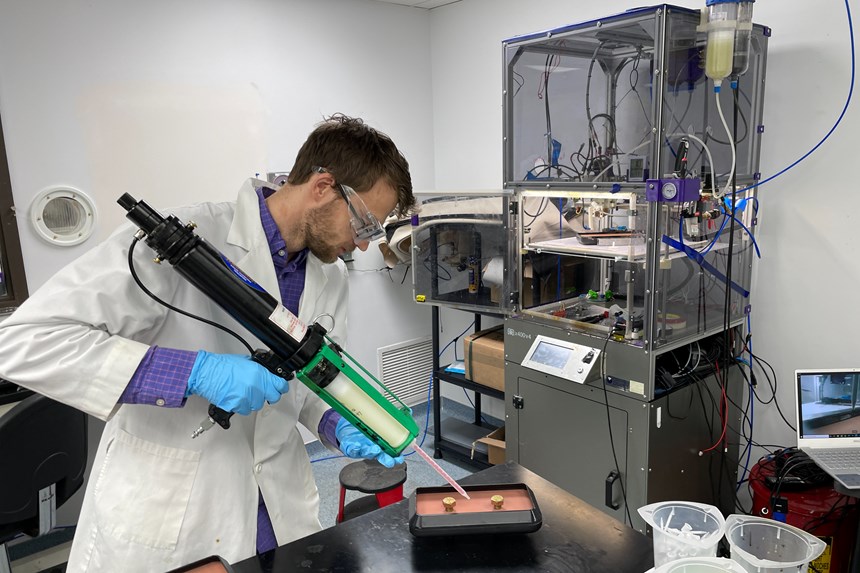

At the time of my visit, staff members were working to fill the company’s first scale production order: 64 tread plates for an antique tractor. Each of these components is an assembly of a machined steel plate, two bolts, and a polyurethane tread produced by printing a wall directly onto the primed steel and then backfilling the void manually with a resin gun. (The fill resin is a different formulation from the border that is optimized for flowability, but it cures to the same chemistry as the printed material — not unlike flood icing on a sugar cookie.) Printing and filling the rubber-like tread directly onto the steel makes it possible to fully encase the heads of the bolts inside and eliminates any other assembly or fastening.

An Old Tractor Gets New Treads

In addition to assembly consolidation, the ability to print on a substrate also potentially reduces the types of materials needed in a component and simplifies its production. In another instance, Chromatic is developing a method to 3D print its materials directly onto a customer’s textile, adding elements to the substrate that otherwise would be produced separately and attached. The current process requires more materials on account of the glue needed to attach the pieces, and has a high scrap rate due to errors in the gluing process. 3D printing the needed features directly onto the textile will help the company reduce waste, eliminate the adhesive, and speed and simplify the production of this product.

Applications like this tend to take Chromatic’s technology into customers with high demand and production requirements. What the company is offering is promising and unusual, but a solution that takes time to develop for any given application. This is okay. The company is committed to working with customers to get the formulation, the parameters and the process right for each specific situation. Part production with its own equipment will be a part of that. So will new materials development (new families of thermoset resins are currently in the works) and resin compounding. 3D printer hardware collaborations and software development are also ongoing projects. Future growth will mean advancing in all these directions, but the diversity of work is not something that worries Leibig. After all, flexibility is all part of the plan.

Related Content

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More

.jpg;width=70;height=70;mode=crop)