July/August 2024 Issue

July 2024

Digital Edition

Features

Featured articles from the July/August 2024 issue of Additive Manufacturing

Quadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read More

The Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read More

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read More

Additive Manufacturing Is in Full Production at Incodema3D

Jim Hockey serves as director of business development at Incodema3D, a shop in Freeville, New York, that makes parts for aerospace, defense, energy, power generation and a few other niche industrial applications with laser powder bed fusion technology.

Read More

What Is the Role of Directed Energy Deposition (DED)? We Are Still Discovering It

The applications go well beyond repair. Recently posted articles find many different use cases for DED, including its expanded application for production parts.

Read More

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read More

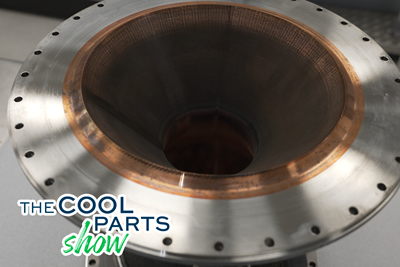

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read More

Formnext Chicago: A Comprehensive Showcase of Additive Manufacturing

Formnext brings together the entire additive manufacturing value chain. It provides a venue for everything involved in AM — from the materials providers to additive equipment, postprocessing solutions, engineering, inspection and software needs.

Read More