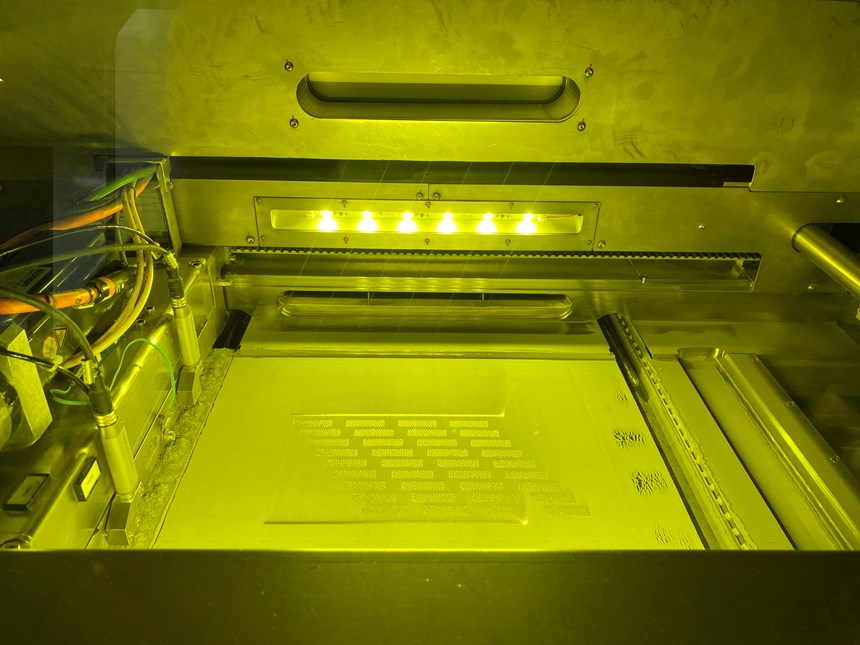

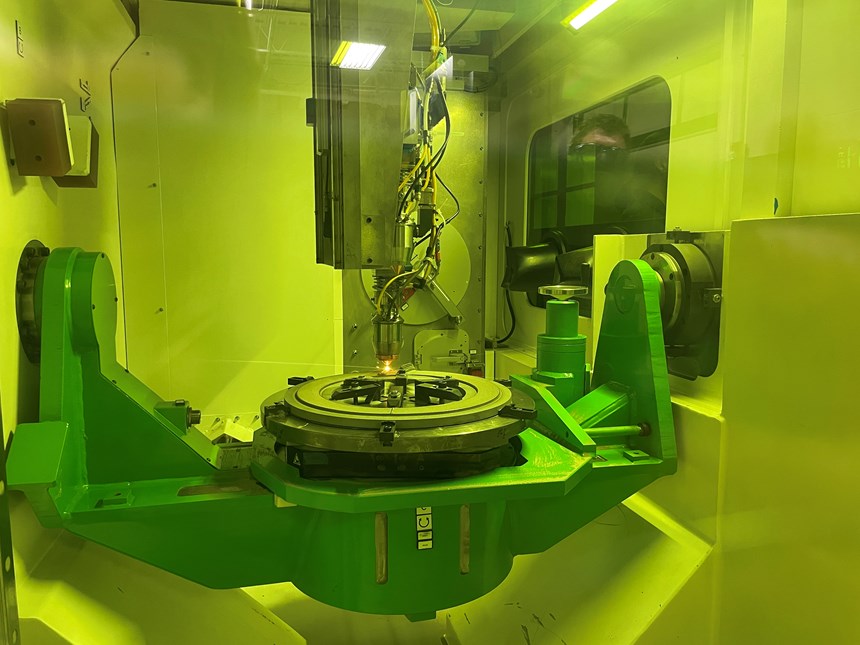

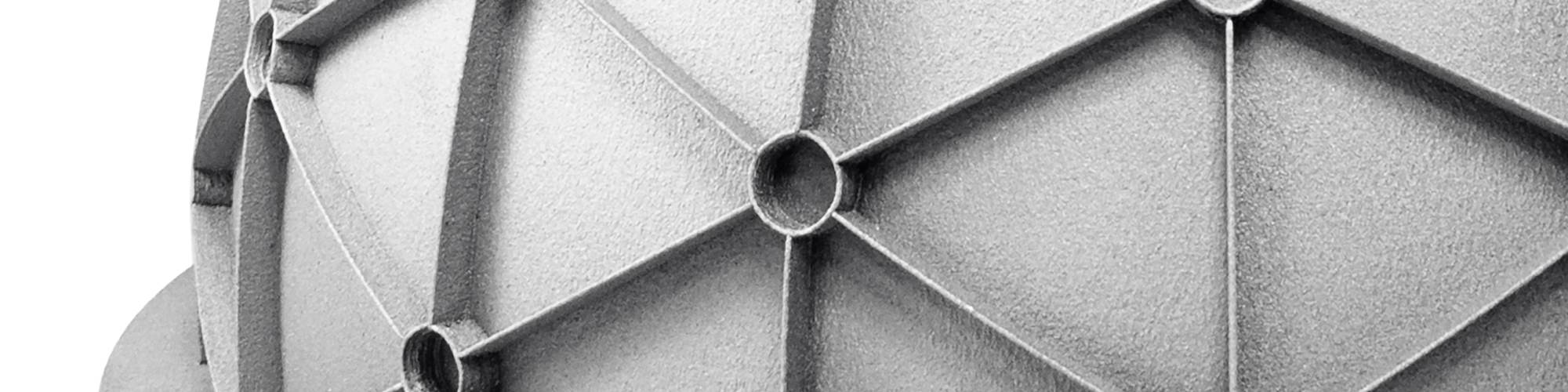

Located in Blue Ash, Ohio, just north of Cincinnati, AddUp’s newly renovated North American headquarters looks not unlike an additive manufacturing production facility. Two directed energy deposition (DED) machines run next door to a room dedicated to laser powder bed fusion (LPBF), populated by six 3D printers. A machine shop around the corner handles postprocessing with depowdering units, wire EDM to remove parts from build plates and some machining capacity devoted to build plate resurfacing; automated postprocessing equipment will be added soon. Quality and metrology equipment are also located on-site, and plans are in place to add a heat-treat furnace down the road.

All this manufacturing capacity suggests a company that is focused on production, perhaps headed toward becoming a full-blown service provider — but this is not the case. AddUp is an equipment supplier, the maker of those DED and LPBF machines, but it is taking a different approach to selling that equipment than others might. As exhibited at an open house held June 22, 2022, its manufacturing capacity at the North American headquarters is meant to be a proving ground, a place to develop the right “recipe” for the application before a customer pursues production.

“We want to de-risk utilizing the equipment, in whatever configuration,” says Rush LaSelle, the company’s recently appointed CEO. The work being done in Cincinnati is an important part of that de-risking, complemented by the equipment builder’s emphasis on usability, safety and reliability in its machines. Key collaborations also play a role, as evidenced by the various partners on site for the event. For a look inside the North American headquarters, see the slideshow below.

Inside AddUp’s North American HQ

See Also: More on Metal AM at AddUp

For a deeper dive on AddUp’s technologies and the manufacturing capacity at this facility, see this LinkedIn post from a preview tour taken in April.

Related Content

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

-

Video: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

.jpg;width=70;height=70;mode=crop)