Additive Manufacturing’s Manifold Benefits

How would you make a weight-bearing manifold without machining?

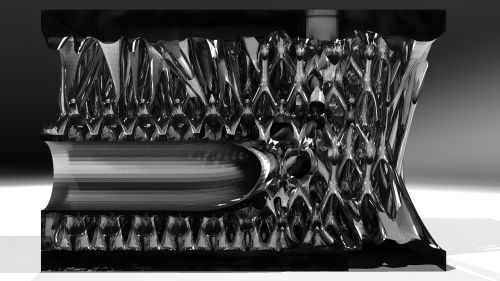

Within Technologies provided the photograph of this part, which was produced additively using a machine from EOS. Within also provided the rendering showing a cutaway of the part’s design. Within makes software tools that simplify the creation of complex geometric structures according to the engineering requirements of a component. Another example of a part designed in Within and produced on a machine from EOS (in this case, at IMTS) can be seen here.

Related Content

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

-

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

-

Top 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.