Additive Manufacturing and CNC Machining: Separate Together? Hear the Recorded Webinar

A maker of CNC machine tools and a maker of AM technology come together to describe integrating additive and subtractive into an efficient process for production.

Wade Anderson of Okuma, a machine tool builder, and Robert Mudge of RPM Innovations, a maker of metal AM technology using laser deposition, recently collaborated to deliver a webinar on integrating subtractive and additive operations into an automated process for part production. Their presentation, “Using Additive AND Subtractive Manufacturing to Multiply Productivity,” can now be heard in its recorded version.

A process that is able to leverage these two capabilities together could generate a finished, high-value part with very little in the way of prior processing. That is, the capabilities of additive could be used to create an intricate part without any need for casting, forging or assembly of smaller components, while machining could then ensure that this part meets tight tolerance requirements for dimensions and surface finish.

But does the use of additive and subtractive together in this way mean that both of the operations ought to occur in the same machine?

Not necessarily, the two men say. In full production, they argue that the more efficient and effective process is likely to be the one that keeps these operations separate, but links them together through some kind of shared automation such as a flexible manufacturing system (FMS). Arguments for keeping the capabilities separate can be found on both the additive and subtractive sides.

Mudge explains why the efficiency of metal AM favors keeping this operation in its own machine. The reasons he gives include:

- Moisture control. The use of coolant impedes control over the argon environment of the laser machine.

- Material efficiency. In a dedicated AM machine, much of the metal powder not used in a given build can be reclaimed. But letting the powder become mixed with chips prevents this reclamation.

- Secondary processing. The part might require a heat treatment process prior to machining. Separating the machines makes it easier for a step such as this to come between the two operations.

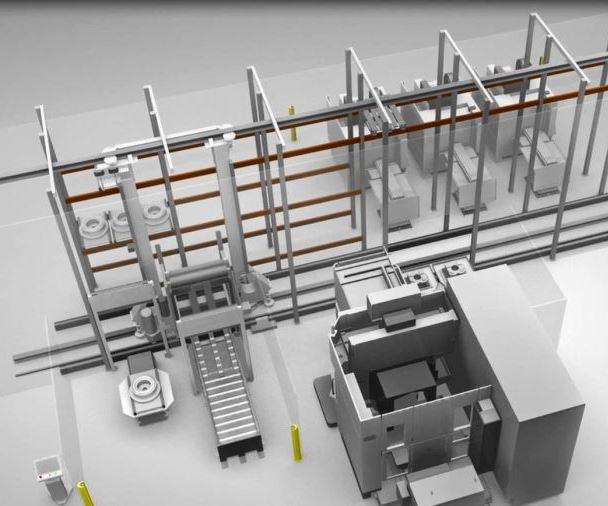

Wade, meanwhile, sees the argument from the machining side. He says, “In the machine tool world, the biggest opportunity we see for efficiency gain is increased utilization.” Combining machining and additive into one machine negatively affects utilization, he says, because it removes opportunities to balance the use of both capabilities. Additive is liable to proceed far more slowly than the subtractive cutting. That is why, in the FMS cell that he and Mudge propose, a single five-axis machining center is sufficient to support the output of three RPM laser deposition machines linked to the same cell. (See video animation of that cell within this article.)

Mudge picks up on the utilization point with a detailed cost breakdown that considers a part requiring 40 hours of subtractive build time and 10 hours of machining. Within the 50 total hours required to make this part, the separation of the two operations between different machines leaves the machine tool open to take on 40 hours of additional work (not to mention freeing up 10 hours on the additive machine).

To see Mudge’s analysis within the full presentation on additive and subtractive, including to the audience questions asked while the presentation was live, view the archived webinar.

Related Content

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreRead Next

The Case for 3D Printing in Machine Shops

A small 3D printer frees up CNC machining capacity by producing tooling and prototypes so the machine tools don’t have to.

Read MoreHigh-Throughput Cell Segregates Additive, Subtractive Processes

The real value of building parts layer by layer isn't the potential to replace conventional, subractive machining, but to complement it.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More