Additive manufacturing is benefiting and advancing as a result of developments in software, business practices and more. Here are some of the trends driving AM or progressing along with it:

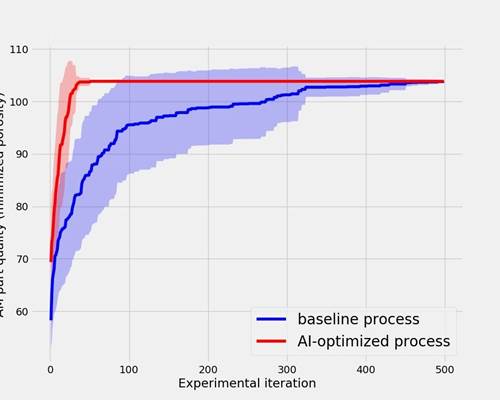

- Artificial intelligence and machine learning. Additive manufacturing is a still-maturing technology, and process development still frequently relies on cycles of trial and error. Yet it is also a digital technology, and the ability to analyze the data used in and generated by the process presents an opportunity to accelerate progress. Possibilities include machine learning to characterize powder and AI-based algorithms that can adjust 3D printing parameters based on feedback from past builds. AI and machine learning cannot replace human judgment, but they have the potential to augment what humans can do and to help advance AM.

- Decentralized or distributed manufacturing. 3D printing does not require tooling, which allows manufacturers to move away from centralizing production in one facility that holds the mold or form. Instead, production can be distributed across many smaller facilities equipped with the right 3D printer and feedstock, allowing for shorter and more stable supply chains. Files can cross borders and travel more easily and rapidly than parts or products, allowing manufacturers to respond more quickly to demand by making these items closer to users.

- Robots and automation. 3D printing is advancing robotics as an option for creating lightweight, functional end-of-arm-tooling (EOAT), jigs and fixtures to assist robot arms and other automation. Simultaneously, 3D printing also benefits from the increased use of automation. Robots can be applied for machine tending of 3D printers to enable continuous production scenarios; robotic arms can also provide the motion for 3D printing systems, offering more axes of movement and large work volumes.

- Simulation. 3D printing enables the production of geometries not previously imagined by human designers; simulation software tools such as computational fluid dynamics (CFD) and finite element analysis (FEA) are needed to inform and arrive at these designs. Another role for simulation in 3D printing is in build preparation and planning; users can simulate how the print will proceed to identify and correct potential problems before it begins for more reliable use.

- Sustainability. 3D printing potentially represents a more sustainable method of manufacturing. It can utilize less material and fewer varieties of them, produce less waste, and create more efficient designs for the next generation of products. 3D printing also provides a potential use for waste streams from other processes, and encourages companies to rethink the design and function of their parts. The disruptive nature of implementing additive manufacturing (as described in the Business Considerations section) also presents an opportunity for businesses to pursue more sustainable, circular operations at the same time.