Sustainment — the ongoing maintenance and repair of existing equipment, including replacing worn or damaged parts — represents a major opportunity for 3D printing in military operations. The U.S. Air Force explored what it would take to not only 3D print but validate a replacement part through its Approval Sprints Challenge, a contest held as part of its Advanced Manufacturing Olympics in 2020. Teams were tasked with developing and 3D printing a clamp that holds two hydraulic lines in an F-16 aircraft. The winning entry seen in this episode was developed by Stress Engineering, Origin and nTopology. Despite a dramatic setback, this clamp prevailed due to its innovative material choice and human-centered design, along with a qualification strategy that could be applied to many more replacement parts in the future. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- More on the Advanced Manufacturing Olympics

- How Stress Engineering assisted with a much larger replacement part, 3 feet long and weighing more than 500 pounds

- How Origin’s materials-focused development informs its 3D printer technology

- More on the distinctive characteristics of Origin’s DLP process

- Another Cool Part optimized with nTopology

Transcript

00:00:00:02 - 00:00:00:15

Pete Zelinski

I’m Pete.

00:00:00:23 - 00:00:11:10

Stephanie Hendrixson

I'm Stephanie and this is The Cool Parts Show. And you know, one of the things we love on this show is a good functional bracket. But in today's episode, I'm going to argue that maybe clamps are the new bracket.

00:00:11:19 - 00:00:16:13

Pete Zelinski

This is a special clamp. It is a replacement part for an F-16 fighter aircraft.

00:00:16:19 - 00:00:22:12

Stephanie Hendrixson

This part looks much different than the part it replaced. It had to be printed quickly and it had to be qualified quickly.

00:00:22:20 - 00:00:37:03

Pete Zelinski

The Air Force held a replacement part contest. This is the winning part. We're going to talk to the team that produced it on this episode of The Cool Parts Show.

00:00:37:03 - 00:00:40:11

Stephanie Hendrixson

This episode of The Cool Parts Show is brought to you by Carpenter Additive.

00:00:40:12 - 00:00:43:19

Pete Zelinski

We're at the company's powder production facility in Athens, Alabama.

00:00:43:21 - 00:00:49:20

Stephanie Hendrixson

Specifically, we are standing on top of the Z1, the company's largest vacuum atomizer for producing metal powders.

00:00:50:04 - 00:00:56:16

Pete Zelinski

Want to know how to make metal powder for additive manufacture? Stick around after the episode. Welcome to The Cool Parts Show.

00:00:56:21 - 00:01:13:22

Stephanie Hendrixson

This is our show all about cool, unique, interesting 3D printed parts. If you like what you see, hit the subscribe button, you'll get notified about all of our new episodes. But today we're talking about this clamp, a replacement part for an F-16 aircraft. This is the literal size of the part, but we'll also be using this enlarged version as a visual aid.

00:01:14:11 - 00:01:51:04

Pete Zelinski

So this clamp was the subject of a competition that the Air Force hosted in 2020, a series of competitions actually, that was called the Advanced Manufacturing Olympics. And the whole point is that manufacturing capability, manufacturing technology are key to the Air Force's mission. And in some ways kind of define what the Air Force is able to do. So the Air Force devised this competition as a way to explore, even push the envelope of what manufacturing is capable of doing.

00:01:51:16 - 00:02:14:04

Stephanie Hendrixson

So this clamp was part of a specific contest called the Approval Sprints Challenge. Basically, what this part does is it holds two hydraulic lines inside of the F-16 aircraft. It's a part that's no longer in production. So teams were given a drawing and some basic information about the component. They were tasked with designing a version that could be 3D printed and also providing a qualification strategy for these parts.

00:02:14:15 - 00:02:32:04

Pete Zelinski

Yeah, and that's really the essence of this. So how can everyone agree that the 3D printed replacement really is a fitting substitute? A variety of different teams took on this challenge and the team we're going to talk to as it happens, they were spread all over the country.

00:02:32:09 - 00:02:57:17

Stephanie Hendrixson

Yes. So this team created the winning part, which you see here. And there were three main collaborators. So Stress Engineering based in Texas and Ohio, nTopology based in New York and origin based in California. So spread all across the country. Nonetheless, they were able to collaborate effectively. And within a period of 4 to 6 weeks, basically accomplish the development work that would normally take place over probably months.

00:02:58:06 - 00:03:18:10

Pete Zelinski

So those companies nTopology, geometric software, Origin, they had the 3D printers and Stress Engineering. They specialize in rapid failure testing of parts, Stress Engineering. That's the first company we'll talk to. Here is Matt Sanders. He's a qualification engineer with Stress Engineering.

00:03:18:17 - 00:03:44:17

Matt Sanders

For the challenge, we weren't given any really design parameters or design guidelines, and so we had to kind of come up with those on our own. So all we were given was like a 1960s drawing of the original hydraulic line clamp. So we had the geometry and we knew what kind of material it would have been made of and what the material performance would have been.

And so we really reverse engineered out what the strength limitations of this legacy design would have been. And we use that as our baseline to say our new design needs to be at this level of strength or better.

00:03:59:08 - 00:04:16:18

Stephanie Hendrixson

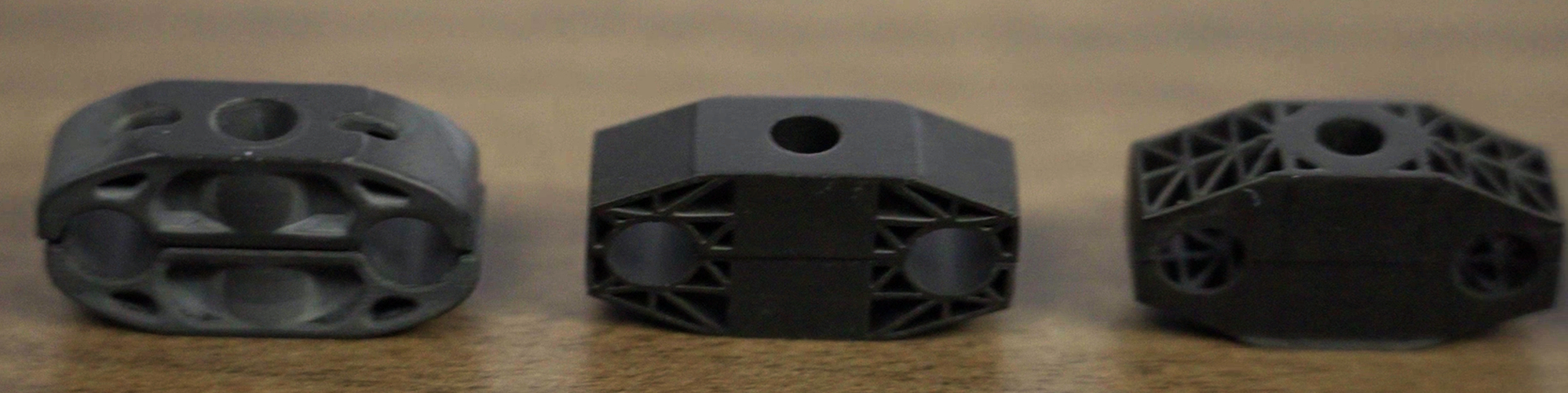

So these 3D printed parts are basically a representation of what the team started out with. They took the drawings they were given, converted them into a model, 3D printed them with fused filament fabrication. Just to get a sense of kind of what they were working with. So I want to introduce another member of the team. This is Ian Muceus,

00:04:16:18 - 00:04:25:10

He is the Industry Solutions Director of Aerospace and Defense for Stratasys, which acquired Origin in late 2020 after the conclusion of this competition.

00:04:25:20 - 00:04:46:00

Ian Muceus

For the Approval Sprints Challenge we basically looked at the part that they gave us, which was a hydraulic line clamp out of an F-16 and a bunch of other aircrafts as well. But basically we looked at that design just as is printed that out and then ran that to stress engineering as is to go through their testing processes.

And there we were able to get a baseline of how that part functioned in a like material. And then from there, we basically improved that part using nTopology’s topology optimization software.

00:04:58:18 - 00:05:19:09

Pete Zelinski

So they got a baseline, established what the original clamp design could do. And then from there, the areas they're free to innovate in were the geometry, the material, but also looking at the part holistically, looking for functionality improvement. That wasn't part of the original design.

00:05:19:17 - 00:05:23:09

Stephanie Hendrixson

Yeah, and they made a lot of different design iterations. We have some of those here.

00:05:24:15 - 00:05:48:12

Matt Sanders

So during the challenge we ended up getting into a design analysis, manufacture and qualification test, iterative process, and we would kind of meet together in the morning with the entire team and kind of brainstorm or talk about any results that we have. And we would come up with kind of a new design feature or something that we wanted to change.

Within a couple hours we were getting that over and CAD’d up and had a new geometry model being produced and done by nTopology, and then that got sent over to Origin where they would then print the new design and do post-processing on it. And while that was going on, we were also running analysis and simulation to get a understanding of how the material would or the new design would perform.

Once it was printed, Origin would then overnight ship the new prototype to Stress Engineering, where we would conduct qualification testing, and then the next morning we would all come together and discuss the results of the qualification testing and the analysis and the print process to see how we can make changes or tweaks. We really got into this daily iteration of designing, analyzing, printing and testing.

00:06:43:10 - 00:06:52:21

Pete Zelinski

So what I can see from all these different iterations, what's clear is the geometry change. All of the different shapes and optimization strategies they were pursuing.

00:06:53:04 - 00:07:11:05

Stephanie Hendrixson

Yeah, so lots of geometric iteration. They also had to contend with what material to make this out of. They didn't really know what the original clamp would have been made out of, even though they had kind of a sense of what its properties were. And so the team sort of narrowed it down to two different polymers and had to make a choice that caused a little bit of internal debate.

00:07:11:19 - 00:07:37:22

Matt Sanders

During the material selection part of the competition. We were fortunate that Origin had a large array of different materials that they could print and we kind of narrowed it down to two different materials. One was kind of a more traditional generic type of material that a lot of people can print, but it did not have the chemical compatibility or flame retardants that we needed.

It couldn't go inside of a fuel tank or maybe in with the pilot, but it was easy to print and a lot of people could print it. There was another material that could go in a fuel tank. It could be exposed to jet fuel and it would not catch on fire. And we really wanted to use that material based on those properties.

However, during the testing, what we found was it was not as ductile as the other material. At the very end we sat down as a team and we said, okay, everybody, which one do we want to be our formal submission? Do we want to submit the traditional material or kind of the more advanced material? And as a group, we really decided that we wanted to shoot for the moon and go for the win, mainly because we wanted to show that additive is always evolving and getting better and can bring value in these aerospace applications.

00:08:29:08 - 00:08:30:04

Pete Zelinski

Okay, shoot

00:08:30:04 - 00:08:38:02

for the moon. That material choice would come back to haunt them. We're going to talk about that. But first, I think we need to talk about this tether.

00:08:38:15 - 00:08:55:02

Stephanie Hendrixson

Yeah. So that's another shoot for the moon kind of example. This is the team anticipating how this clamp would be used, thinking about how it gets installed and trying to make some improvements there. So the way that this clamp looks when it is actually in the aircraft is something like this. Two halves of the clamp around the hydraulic lines.

There's a screw that goes through the center and then there's a nut on the other side. And so if you think about the person installing this in the aircraft, there's a lot of stuff that they have to hang on to and keep track of. So by adding this tether that holds the two halves of the clamp together and also holds that screw in place, you're making it easier to just keep track of all these little parts, keep them all together.

00:09:15:08 - 00:09:27:13

Pete Zelinski

This is all one 3D printing build. Even though the tether and the clamp material, they are two different substances. How is this tether joined to the two clamp halves?

00:09:27:22 - 00:09:44:12

Stephanie Hendrixson

Yeah, so that's the thing. It's not really joined. It's sort of printed together. So I'm going to let Ian explain how that works. But just for context, these parts were made on Origin DLP printers, so digital light processing. So imagine like a vat of resin and then a build plate that's rising as each layer is getting cured.

00:09:44:22 - 00:10:16:05

Ian Muceus

How we printed this actually was very interesting. So this is actually printed in one part, not the bolts or screw, obviously. But we printed sort of the tether first and then we actually, when we were done printing the tether, switched materials. So with the Origin one printer, we're basically able to do a print routine where we can add in a pause in the process, bring the build head up to its home station, replace the tray with a new tray, take the build head and clean the old resin off of it, and then restart the operation with the new resin.

And we went from something where we're printing a high viscosity elastomeric resin to printing a high temperature resin where we had to turn up the temperature in the chamber and interface with the printer to about 60 degrees C. So it's a pretty complex operation. But something that's, you know, enabled basically by the Origin One print parameters and how we're able to change them on a layer by layer basis.

00:10:41:01 - 00:10:50:05

Stephanie Hendrixson

All right. So we've talked about the design choices. We've talked about the material, actually the materials that are represented in the final version. Now, I think we need to talk about what happened during the competition.

00:10:50:14 - 00:11:07:06

Pete Zelinski

Yeah. So these parts went to the Air Force. Each of the parts from the competing teams went for installation in an F-16. Air Force technicians installed each of the parts in the plane and this team's part broke, it cracked during installation.

00:11:07:10 - 00:11:11:23

Stephanie Hendrixson

Yeah, going for that FST but more brittle material actually led to the part breaking.

00:11:12:06 - 00:11:16:04

Pete Zelinski

And let's say arguably, it wasn't the material's fault. Here's what happened.

00:11:16:17 - 00:11:38:09

Matt Sanders

We were kind of watching the competition live with everyone else and we saw our part and we all recognize it, and they showed a video of it cracking. I'm on the West Coast. It started pretty early. I woke up a bit late and had gotten all these texts and everyone was sort of, you know, it's kind of like a doomsday sort of text. I guess

00:11:38:13 - 00:11:59:22

Ian Muceus

what happened is in the video, they basically didn't listen to our torque spec, cranked down on the part. And obviously it's a brittle part. So past our torque rating and a factor of safety, it just ended up breaking. And so everyone was thinking we just had no chance. And we were done for.

00:11:59:22 - 00:12:23:04

Matt Sanders

We didn’t know that we had won until the moment that it was announced. And once it was announced, it was awesome. I think we won because we tried to showcase how additive can really be a game changer. We used some things that only additive can do. It kind of took, you know, at least the two assemblies, really the three with the bolt and combine it into one. And that entire assembly could be serialized for tracking.

And it made it much easier to install the clamp. Not only that, but also our qualification strategy was very strong.

00:12:30:23 - 00:12:55:23

Stephanie Hendrixson

So Matt mentioned that qualification strategy and that's a big part of this competition. The Air Force is not just interested in solving this problem for this one particular clamp on this one particular aircraft, they’re looking for a solution that could be applied to lots of different parts across lots of different aircrafts. And so along with actually 3D printing and delivering a physical clamp as part of this competition, each of the teams had to also create this qualification strategy.

00:12:56:09 - 00:13:25:07

Matt Sanders

So the qualification strategy that we developed and presented as part of the challenge, we kind of coined the term eQual and it was really based on having kind of a living qualification for parts and part families where there would be kind of a dynamic database where data was constantly being fed into it. And as the performance of parts were being evaluated, it would go into a depository where that can then be used for redesign.

And as parts were being designed or modified, it would continually update this database that designers or engineers or operations staff could go into and utilize to help continuously qualify parts and really serve as a living qualification for different additive parts.

00:13:46:21 - 00:14:11:07

Pete Zelinski

So there's a point to all this this. This competition, it's bigger than any one 3D printed part. It's bigger than any qualification strategy. The point of all this is how do you use and rely on 3D printing as a means of making replacement parts, replacement parts as they're needed to keep vital military hardware running, including aircraft. The military's term for this is sustainment.

00:14:15:03 - 00:14:45:23

Matt Sanders

This project really shows that additive can be used for sustainment and it can be done in a very quick and rapid way. And not only that, but it doesn't mean that you have to print something and install it and hope that it works. You can really do qualification both on the design side and in the actual physical parts in a very short period of time, which allows you to keep things up and running and sustained through additive manufacturing.

00:14:46:04 - 00:15:07:16

Ian Muceus

I would hope, you know, as an outcome from all of this, we just have a little bit more faith in additive. Of course, we test, verify, retest, but at the end of the day, I think we just need to really look at additive as a serious technology in this space that can produce parts that really solve some of these problems around sustainment and part obsolescence.

00:15:08:10 - 00:15:20:17

Pete Zelinski

So let's recap. So the Air Force hosted a competition, quickly 3D print a replacement part for a clamp that secures two parallel hydraulic lines in an F-16 aircraft.

00:15:21:06 - 00:15:43:16

Stephanie Hendrixson

We have the winning entry here in the studio with us. This clamp was developed by a team consisting of nTopology, which brought the design expertise, Origin which had the 3D printing knowledge and Stress Engineering, which did the simulation testing and analysis. The team was spread all across the country, but nonetheless they were able to do a lot of different design iteration in a very short period of time.

00:15:44:12 - 00:16:09:05

Pete Zelinski

And they didn't just look at the geometry, they looked at the overall ergonomics and functionality of the part. They created this tether that makes it easier to install and that tether section of the of the two halves of the clamp, it's all part of the same 3D printing build. And that's accomplished by basically switching material trays mid process.

00:16:09:19 - 00:16:29:12

Stephanie Hendrixson

When the clamp was installed in an F-16 as part of the competition, it actually ended up cracking, but nonetheless, this team still prevailed and won, probably because of a couple of reasons. So they took a risk and they chose that more advanced material. They thought about the ergonomics and the usability of this part and developed the tether solution to make it easier to install. And they also created a good qualification strategy that could be used as a framework for other replacement parts going forward.

00:16:36:06 - 00:16:41:20

Pete Zelinski

Okay. So that has got to be the most dramatic clamp story we will ever tell on The Cool Parts Show.

00:16:41:20 - 00:16:42:09

Stephanie Hendrixson

Never say never.

00:16:43:01 - 00:16:56:21

Pete Zelinski

If you have a dramatic story to tell about your clamp or bracket or gasket that was made through 3D printing, we want to hear it. We live for this stuff. Email us. CoolParts@AdditiveManufacturing.media.

00:16:57:08 - 00:17:07:12

Stephanie Hendrixson

If you like the episode, if you have a question or comment, let us know below. And if you like the show, we hope you'll subscribe. Share it with a friend and click the Bell notification to get notified about all of our new episodes.

00:17:08:07 - 00:17:30:03

Pete Zelinski

This episode is brought to you by Carpenter Additive. We are at the company's powder production facility in Athens, Alabama, and we are standing on top of an atomizer. The Z1 is Carpenter Technology’s largest vacuum atomizer and it is the heart of the process for making additive manufacturing metal powder here at Carpenter Additive.

00:17:30:10 - 00:17:38:13

Stephanie Hendrixson

This facility is capable of producing up to 18,000 pounds of metal powder per day. Plant manager Jordan Ralph talked us through the process.

00:17:39:01 - 00:18:09:15

Jordan Ralph

So an atomizer is a piece of equipment that is capable of melting and pouring molten metal into the stream of high pressure gas that turns that molten metal into tiny, tiny droplets that ultimately cool and form our powder, which looks like a gray dust. So to start our process and the ultimate in the end solution that we have here, we bring in raw materials all the way down to individual elements.

00:18:09:15 - 00:18:41:20

So nickel, cobalt, chrome, moly, niobium, we bring all of those raw materials into the shop. We utilize those materials to build charges that go into the atomizer. As you walk that flow path, you run through our charge make up area where all of the materials are weighed out in very exact quantities. That ensures that we're able to hit our customer specifications and hold the tight tolerances that we're looking for on a chemistry perspective.

00:18:42:23 - 00:19:09:09

From there, the material is flown to the top of the atomizer and charged into the furnace. As the material is produced, it is poured out and is collected at the bottom of the atomizer. The material is then taken and transferred into a bulk container for processing through the rest of the value stream. The next stop for any of our atomized powder would be the screener.

00:19:10:08 - 00:19:36:23

So that will remove the coarse portion of the powder. From there we take it through air classification. That takes the fine portion of the particle size distribution out and makes the final cut for an additive material like a 10 to 45. From there, we stack up all of those individual lots and put them into the 12,000 pound blender to make the single homogenous blends.

00:19:38:00 - 00:20:35:05

At that point we are able to pack in any configurations the customer's looking for, whether that be drums, bottles, PowderTrace hoppers. We've got a lot of options to meet customers needs there. The atomization, capability and all of the powder capabilities gives us a unique position where we're actually able to produce the powder run testing through additive machines all the way through HIP and heat treat, do final testing on those products, and then make additional changes or try to optimize, things like our chemistry or sizing so that we ultimately can serve our customers better.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreFor Stratasys, Acquisition of Origin Part of Strategy Focused on Production and Polymer Materials

Americas president Rich Garrity describes how the two additive manufacturing technology companies came together (COVID-19 helped), along with the value of protecting one culture while allowing another to change.

Read More

.jpg;width=70;height=70;mode=crop)