Which AM Event at IMTS Is Right for Your Business? AM Radio #22

IMTS 2022’s two additive manufacturing-centered events are designed for different audiences.

Share

When IMTS returns to McCormick Place in September, it will include two separate, co-located events focusing on additive manufacturing, each targeting different use cases within additive manufacturing. The first is the Additive Manufacturing Conference, which takes place September 14 and 15, 2022. The conference is geared toward owners, executives and engineers at contract manufacturers and OEMs involved in durable goods manufacturing, and focuses exclusively on using additive for industrial part production. The agenda covers AM applications and technologies, as well as enterprise transformation and even soft skills required as businesses in a range of end markets (including aerospace, medical and tooling) either advance with additive manufacturing or make a transition to AM.

The Additive Manufacturing Conference is now Formnext Forum Austin.

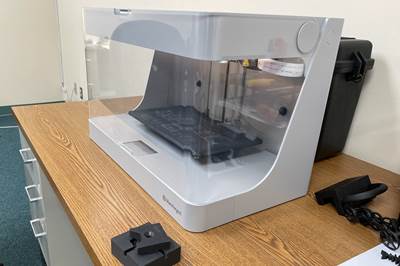

The second event, the 3D Printing Workshop for Job Shops, is new this year. It’s a half-day seminar on September 15 that focuses on how machining facilities including small shops are using lower-cost 3D printing technology as a complement to machining. Speakers will discuss ways they have used 3D printers to create tooling that aids machining and for production that doesn’t make sense on traditional machine tools. The lineup of speakers and information on how to register can be found at additiveworkshops.com.

Registration to both events includes access to IMTS, so attendees can visit the show floor and learn more about the technologies discussed at the events. IMTS has a dedicated Additive Manufacturing Pavilion with more than 80 exhibitors, and AM will factor into other booths across the show floor as well.

On this week’s IMTS pre-show episode of AM Radio, we give previews of both events starting at 9:43. Listen to the episode above, or find the show notes and transcript below.

Transcript

Peter Zelinski

We're getting close to the historic return of the International Manufacturing Technology Show, which has become a major event for additive manufacturing. Getting ready for IMTS on this episode of AM Radio.

Stephanie Hendrixson

The AM Radio podcast is brought to you by The Cool Parts Show, a video series dedicated to highlighting unique, unusual and innovative 3D printed parts. Watch episodes at TheCoolPartsShow.com.

Peter Zelinski

Welcome to AM Radio, the show where we tune in to what's going on in additive manufacturing. I'm Pete Zelinski, and I'm here with Julia Hider.

Julia Hider

Hey, Pete.

Peter Zelinski

So Julia, you doing anything in September?

Julia Hider

Yeah, I think there's this pretty big trade show that we have coming up in September.

Peter Zelinski

I've heard about that as well.

Julia Hider

Kind of hard to avoid thinking about it at this point.

Peter Zelinski

Totally. Yeah, totally.

Julia Hider

Yeah. So IMTS. It's the biggest North American trade show that covers manufacturing, it takes place in September at McCormick Place in Chicago, takes place every two years. And it just covers everything that you could think of related to manufacturing, from machine tools to cutting tool software and additive manufacturing.

Peter Zelinski

Yeah, so a week or so ago, this podcast taping was approaching and we were, you and I, were wondering what we would talk about on this episode. And like the question was sort of low-key exhausting, because we've got all this other stuff going on the, like not getting into the weeds too much, but the pre-IMTS period is our busiest time. There's a there's a variety of extra work we need to do that relates directly to the fact that IMTS is coming, International Manufacturing Technology Show, but then like it became clear, yeah, a whole lot of our world is doing the same thing, starting to look toward IMTS. So, so that's a topic worth talking about. IMTS is put on by AMT, the Association for Manufacturing Technology, and like just being clear upfront about our interests here. We, our company Gardner Business Media, we partner with AMT in various ways. Among other things, AMT is a supporter of Additive Manufacturing Media. They have been from the beginning. This is our ten-year anniversary of this brand. And they've been with us the whole ten years. They've also been our partner in the Additive Manufacturing Conference that we brought to every IMTS since 2014. And that's going to be returning to IMTS this year in a way that's pretty great. We'll get to that. So so just being open. Like there's, there's no way to talk about IMTS without touching on a lot of stuff we have an interest in. But we need to talk about IMTS on this podcast. And here's why, I think. IMTS has made itself a major platform for additive manufacturing technology. That was a deliberate choice resulting from AMT’s ongoing commitment to additive over the course of years. The additive manufacturing pavilion at IMTS has over 80 exhibitors now and, and that doesn't count all the ways that additive technology is going to figure into other exhibitors’ booths throughout the show. And in addition to that, the Additive Manufacturing Conference, this two-day event is a major additive event within the show. So IMTS is now I would say, the most important event for additive manufacturing that is not strictly focused on additive manufacturing. I guess I want to start, Julia, I'll just like, let's ask you how you're thinking about the show this year. This year, you're going to be focused on additive manufacturing. As we discussed in the now classic meet Julia episode of AM Radio, like you've, you've been writing about manufacturing for about five years now, which in Gardner Business Media terms is actually pretty short tenure. And you've been on different brands, you've been on Modern Machine Shop, on Production Machining. And because of pandemic drama, this is going to be only your second IMTS. It had to be canceled the last time it was held or was going to be held in 2020. Yeah. Talk about that a little bit. How are you thinking about the show this year? Um, what are you expecting? What will you do at IMTS?

Julia Hider

Yeah, so like you said, I've only had the opportunity to attend one IMTS before back in 2018. And I had just started writing for Production Machining at the time, so this is the first time that I'm going to be going as an Additive Manufacturing editor and I can already tell that it's going to be a very different experience. Last time, I didn't attend any of the conferences that were co-located so I'll get to do that this year, you know, just the way that the additive companies treat the show is very different than the way that, you know, machine tool OEMs treat the show, just because, like you said, this show isn't focused on additive manufacturing. So it's sort of a different audience. They have different goals.

Peter Zelinski

Yeah, that's, that's for real. Like we've started to talk to additive manufacturing exhibitors who are getting ready for the show. And, and it's a different audience. It is manufacturers, a lot of them aware of, knowledgeable about additive manufacturing, who maybe aren't quite there yet, but are going to be there. And that affects like what they're bringing to the show, how they're thinking about their exhibits and messaging at the show, and it's a great opportunity for them.

Julia Hider

And it also affects, you know, how I plan my time at the show, it'll be really nice to have a lot of the companies that I want to visit in the additive pavilion instead of having to walk all over McCormick Place to visit everyone I want to see.

Peter Zelinski

There is that. McCormick Place is huge. It's the biggest event place in North America and IMTS almost fills it. But yeah, the additive manufacturing pavilion is in one place. So like pedometer steps will be smaller.

Julia Hider

One thing that I think will be really interesting about this IMTS is because the last one was cancelled due to the pandemic, so there's been a four-year gap, instead of the usual two-year gap. And I was talking with someone from Stratasys, about their booth. And she said that they have really so much new technology in the last four years that all or almost all of the machine tools that they have in their booth will be ones that they've never showed at IMTS before. So, you know, so much has changed in these four years, since the last time the show was held just in terms of technology and business.

Peter Zelinski

The four-year gap is a big thing. Like I think that's what makes this show so historic, how much time has passed and how much the industry has moved in that time, how much technology has moved. And additive is the area of the show that's going to show the, the most marked change. But you mentioned Stratasys, but even Stratasys has become a different company almost in that time. I don't remember, for example, exactly when the acquisition of Origin happened since, but it happened during that, like it happened during the pandemic. And so. So just the array of technology that Stratasys is bringing to market and what they represent and the kind of solution provider they are. It's almost like yeah, they're, they're reintroducing what kind of company they are, what role they play. So I guess what that reminds me of is a recent conversation I've had is with Nexa3D. They will have a large booth in in the additive pavilion and it's going to emphasize automation. So they have different kinds of 3D printing solutions, they'll show they'll be showing photopolymer and SLS among them, but they're mostly going to emphasize automation, like they want to show additive, not just as a solution for making parts, but as a system for ongoing production. So like they'll have autonomous, an autonomous robot, they'll demonstrate loading and unloading the photopolymer machine. I think a lot of people maybe have seen this, but it's the Boston Dynamics robot, the robot dog and like, yeah, that's always been the thing about IMTS, not enough robot dogs. And their SLS system, they're going to show the build chamber with all the powder in it, it can come out autonomously, and a different one can load itself in. But it's like production that they're showing. And it's going to be a major demonstration of what's possible at IMTS. But all that to say, Nexa3D, the last time IMTS was held, that's not a company that would have been a familiar name, I mean, to the point where I even went back and like validated for myself when did, when was Nexa3D founded? And it was before the most recent IMTS. But not much before that. And it kind of illustrates it is possible and still commonplace for new providers to appear and if they have credible solutions, they can become relatively established names pretty quickly. And so there's going to be like this landscape, this additive landscape at IMTS. That's going to look different.

Julia Hider

All right. I will add that to my list to check out the robot dogs in the Nexa3D booth. I'll add that to my IMTS schedule.

Peter Zelinski

They'll be at our conference, too. They'll be at the Additive Manufacturing Conference. They're actually one of the lead sponsors of our conference.

Julia Hider

Nice transition, Pete.

Peter Zelinski

Thank you, thank you. Let's treat that as a segue. You want to talk about our conference.

Let's do it.

I kind of love our conference. I mean, and I'm like totally biased. It's our event, but the Additive Manufacturing Conference, this event we have the opportunity to put on, it's not like nothing else in the additive manufacturing space. We focus on production, the possibilities of additive, the promise of additive for part production. And we focus on all of the changes and transformation that come from that and are required for that. We talk about enterprise type stuff and workflow organization type stuff, and and the ways that additive manufacturing is a different kind of production with different design and deliverable possibilities than the production modes we're used to. And so, like the, the result of that, this this interesting thing we've seen, when the, when the conference comes to IMTS, which is where it's been in every IMTS year, like you would think we would get the IMTS audience as attendees to the conference. And we do, but we also get these different types of leaders from within manufacturing enterprises, including executives, in some cases, of larger companies, where they're not necessarily in direct contact with, say, the manufacturing engineering on a day-to-day basis, but it's like the chance to come to IMTS, which is what they get along with coming to our conference. It's like this added bonus for them. So we get IMTS attendees who see our conference as an interesting extra, and we get conference attendees, who see the chance to like take in IMTS as the extra and like, like that whole circle of that whole diversity of manufacturing leadership is in the same room together all through our conference, which runs a day and a half at the show.

Julia Hider

Yeah, I was looking at the lineup of speakers that you have recruited for this conference this year and it's really good, you can tell that it's focused on, you know, enterprise leadership and production, and that's who the audience is. But at the same time, it covers a really broad range of topics, you know, there's polymer and metal, there's a bunch of different end markets, like aerospace and medical and tooling. It covers the entire manufacturing process from design to post-production. And there's a good mix of technical information and soft skills in there, too.

Peter Zelinski

Yeah, soft skills. So like one of the talks is being given by Tim Simpson, who writes for Additive Manufacturing Media all the time. He's a professor at Penn State. He's the leader of their additive technology group on the Penn State campus. He's one of the leaders of its Center for Innovative Materials Processing Through Direct Digital Deposition. I think that's right. Complicated acronym. But anyway, he's giving this talk about training for, for additive production, it's a big deal, the personnel aspects of additive are getting to be a big deal, as more and more of the promise of production is realized. And he's had the chance to kind of watch what works and what doesn't work as far as developing people for additive processes, developing people who can oversee this technology, how is it just like, the manufacturing skills that and knowledge that we're used to how does it require a different mindset? And he's gonna talk about that. You mentioned, the presenters I've recruited. So just saying I'm, I'm part of a team that put the program together. I'm very proud of the lineup of presenters we have. And I feel like pretty solid, like this is the best lineup of speakers, we have, in large part because we're figuring out better year after year, like when our conference is really valuable and the kinds of issues it speaks to well, some of these are speakers that I have reached out to, but a lot of them are speakers who, who answered the call for speakers we put out earlier in the year and we get when we do this call, we get a lot of response. And I'll tell you, we get a lot of speakers who what they're offering it's like, super interesting and it's almost, but not quite right. Because what we try to do with this conference, it is one track all the way through, we don't ask the audience to separate, there will be hundreds of people in the room all at the same time. But we look for topics like and just like you say, it's part production. It's tooling. It's polymer, it's metal, but we focus on the transition. And we sort of emphasize the issues that manufacturers and manufacturing enterprises at all different sizes and all different sectors, the kind of larger issues they have in common as they try to, over the long term, make this change, make this shift toward bringing additive in as a significant part of their production. And the conference sort of speaks to that.

Julia Hider

Pete, if someone wanted to learn more about the Additive Manufacturing Conference and possibly register, how could they do that?

Peter Zelinski

Yeah, that's a good question. Thank you for giving that to me. It's AdditiveConference.com AdditiveConference.com. Please join us, Julia and I will be both be there. Stephanie Hendrixson will be there. We'll, we'll be taking it in with you. And we're looking forward to it. It won't be our only event actually at IMTS. There's something new, we're debuting, too, another another event, a workshop that's a little more focused than this. You want to talk about that right after the break?

Julia Hider

Yeah, that sounds good.

Peter Zelinski

I'm Pete Zelinski.

Stephanie Hendrixson

And I'm Stephanie Hendrixson.

Peter Zelinski

You've heard us on AM Radio, but we want to tell you about another great place to learn about additive manufacturing: our video series, The Cool Parts Show.

Stephanie Hendrixson

In each episode, we highlight a cool 3D printed part that has something to say about where additive manufacturing is headed.

Peter Zelinski

Join us as we explore the world of custom medical devices, try on the next generation of sustainable footwear and even follow 3D printed parts to Mars.

Stephanie Hendrixson

Find all the episodes and subscribe on YouTube or at TheCoolPartsShow.com.

Peter Zelinski

And we're back. Julia Hider and I are talking about IMTS-International Manufacturing Technology Show coming in September, major destination for manufacturing in general, but for additive manufacturing, too. Before the break, we were talking about our Additive Manufacturing Conference, which returns to IMTS. There is another smaller event, Julia, that you and I have put together. You want to talk about that?

Julia Hider

Yeah, so this is the 3D Printing Workshop for Job Shops. It's new this year. It's a half day workshop on the afternoon of September 15. And it's just focused on how machine shops are using 3D printers in various ways. And all the 3D printers that we'll be talking about at this workshop are in the price range from a mid-range machine tool down to a desktop printer. So it's technology that shops can easily implement. And it'll cover tooling and other ways that 3D printing can be used to help machining as well as using 3D printing for part production runs that don't make sense for traditional machine tools. And I think people are going to find it really interesting and useful and that they'll be able to take things that they learn here and actually apply them to their shops.

Peter Zelinski

3D Printing Workshop for Job Shops. Yeah, so we were just talking about the Additive Manufacturing Conference, and it has become this particular thing and it's kind of focused on enterprise transition toward production through additive. But meanwhile, there are all these uses for 3D printing that established machine shops, particularly small independent shops can take advantage of and we decided to create this focused half day event, just like you say, around ways that businesses focused on machining can use 3D printing as a complement to that. Let's describe a couple examples, like, pick one of our speakers and sort of talk about them.

Julia Hider

Yeah, one of the ones is Steve Michon from Zero Tolerance Machining. And he has a really interesting story. It sort of ties into some of the stuff we've talked about on the podcast about Project Diamond. He is one of the recipients of a Markforged 3D printer through Project Diamond and how he is using that around his mold and tool shop. He has a bunch of interesting applications and he actually brought some previous 3D printing experience to that as well. So it'll be really interesting to hear all of the ways that he's using that 3D printer around his shop.

Peter Zelinski

Right. He's, he's, he's another example of this phenomenon we keep encountering, like, once he got his 3D printer into his shop, he started finding all of these uses for it. Another presenter we will have at the Workshop, Professor Tony Schmitz, University of Tennessee, Knoxville, and his talk is going to largely focus on ways 3D printing can actually aid the precision of machining in his facility at the University of Tennessee and the kind of work they're doing. He's had a lot of success with using 3D printing to make not parts, not fixtures necessarily, although I think he does do both of those things, but dimensional aids for machining references for machining, things to measure as part of the machining process that in an efficient way, set up the overall machining cycle for success and for tight tolerance work. And he can kind of talk about how he's doing that. And again, it's 3D printing as an enabler to using machining more effectively, which is sort of the overall theme of the workshop. And again, just as you said, it's like, it's not the entire range of possible additive manufacturing equipment we're talking about, but 3D printing technology that's of a class that is that is economically accessible to machine shops. And so yeah, we'll talk about tooling, prototyping, part production of parts that maybe are better for 3D printing as opposed to CNC machining, all of that in the 3D Printing Workshop for Job Shops. Julia, if people are interested in learning more about the workshop, how can they do that?

Julia Hider

Yeah, you can find the whole agenda and information on how to register at additiveworkshops.com. Okay, Pete, there's one more learning opportunity, we'll call it, at IMTS that I wanted to ask you about and that's the AM4U, I know that we Additive Manufacturing Media have some things going on in the AM4U Booth. But can you explain you know what this is going to be and how we fit in?

Peter Zelinski

Yeah, AM4U, something else that will be new at IMTS this year. AM4U is this area of the additive manufacturing pavilion that will be hosted by formnext. formnext, biggest additive manufacturing event in the world held every year in Frankfurt, Germany, something really big is happening in the event space around additive, as additive manufacturing takes its place in production. And, and that is that formnext is coming to the United States. It won't happen immediately. And we talked about the rollout in in an earlier episode of the podcast, and we'll link to that in the show notes. But in 2025, there will be a full-scale trade show formnext USA in Chicago. AMT, who we've mentioned, the creators of IMTS is one of the partners with the formnext organization in bringing the show to the United States and our company Gardner Business Media is in that partnership, too. So at IMTS, AM4U is like among other things, this live stage that formnext will host at the show for speakers on various additive related topics, including, I'm reading from imts.com here, entrepreneurship and business models. But yeah, The Cool Parts Show is going to be onstage at AM4U on Monday, we're putting together a panel discussion among manufacturers who have appeared on the show, we're gonna have a live discussion there. Hopefully we get audience Q&A, like we're gonna, we're gonna film that and I think maybe turn that into an episode of The Cool Parts Show. That's on Monday of the show. And then this podcast, AM Radio, is going to be there, too.

Julia Hider

Yeah, I'm really excited. It'll give us an opportunity to discuss you know what we saw at the show, while it's still fresh in our minds while we're still there. So I think that'll be really exciting.

Peter Zelinski

We've never done a live taping of the podcast before. What do you think about that?

Julia Hider

I think it'll be interesting. We have to do a lot of takes sometimes. So we'll see how this goes in front of a live audience.

Peter Zelinski

A lot of takes? I think the audience should know that what they're hearing was just as we spoke it straight through.

Julia Hider

Yes, we're 100% perfect every time.

Peter Zelinski

Yeah, so our first attempt at a live taping of AM Radio, it's going to be fun That's going to be Friday of the show. We would love to meet some listeners. So please come watch us do our taping. And then like, stick around and say hi. We'd love to talk to you.

Related Content

-

Video: Robot Machining Will Complement Robot DED

Robots can do additive manufacturing. Can they do hybrid manufacturing? Precision milling of metal using a robot offers this promise.

-

6 First-Time Additive Manufacturing Exhibitors at IMTS

Find these companies that are exhibiting for the first time in IMTS’s Additive Manufacturing Sector (in the West Building). Their offerings include printers, parts and powder, with areas of expertise ranging from large-format to atmosphere control to supply chain solutions.

-

3D Printing Solutions to Support Investment, Sand Casting

3D Systems is highlighting a design strategy for better investment casting patterns, as well as a new machine suitable for the production of patterns for sand casting.

Related Content

Video: Robot Machining Will Complement Robot DED

Robots can do additive manufacturing. Can they do hybrid manufacturing? Precision milling of metal using a robot offers this promise.

Read More6 First-Time Additive Manufacturing Exhibitors at IMTS

Find these companies that are exhibiting for the first time in IMTS’s Additive Manufacturing Sector (in the West Building). Their offerings include printers, parts and powder, with areas of expertise ranging from large-format to atmosphere control to supply chain solutions.

Read More3D Printing Solutions to Support Investment, Sand Casting

3D Systems is highlighting a design strategy for better investment casting patterns, as well as a new machine suitable for the production of patterns for sand casting.

Read MoreHeron AM Offers Robotic LFAM for Composite Pellet Extrusion

The integrated Heron AM system opens up new opportunities for manufacturers seeking to drive new applications more efficiently and sustainably.

Read MoreRead Next

What a 3D Printing Workshop Can Show You

Half-day seminar — co-located at IMTS in Chicago’s McCormick Place — focuses on applying 3D printers for tooling and running parts that don’t make sense on traditional machining centers.

Read MoreAdditive Manufacturing and the War in Ukraine: AM Radio #19

In this latest episode of the AM Radio podcast, we dive into the ways that AM is providing aid and also being affected by the conflict in Ukraine.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More