Impressions and Trends from RAPID + TCT 2021: AM Radio Bonus

Peter Zelinski, Stephanie Hendrixson and Julia Hider discuss what they saw, heard and learned at RAPID + TCT 2021 in a special episode of the AM Radio podcast plus slideshow.

Share

Sights from RAPID + TCT 2021

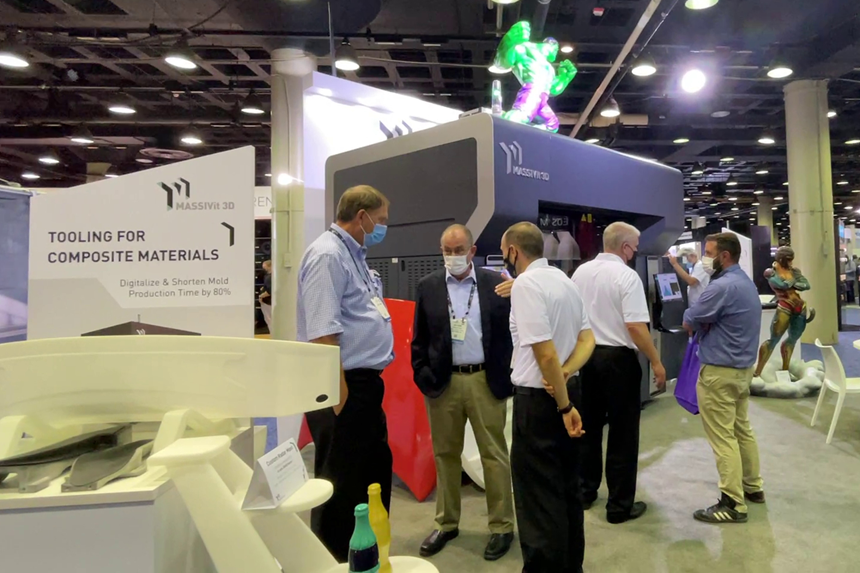

RAPID + TCT 2021 was distinctive as the first major North American trade show for additive manufacturing since 2019, but also for the themes and technological advances evident on the show floor. Held at McCormick Place in Chicago, this year’s “Rapid” featured more than 250 exhibitors showcasing new machines, materials, software and applications. While attendance was lower than in years past and masks were required throughout the venue, spirits were high among both exhibitors and visitors.

In this special episode of the AM Radio podcast, hosts Peter Zelinski, Stephanie Hendrixson and Julia Hider share their impressions from the show as well as five major themes they observed. Above, listen to the episode and flip through a slideshow of photos related to the conversation, or read on for the transcript.

Transcript

Stephanie Hendrixson

Hello and welcome to AM Radio, the show where we tune in to what's really going on in additive manufacturing. We just had a great chance to do that at RAPID + TCT held this year in Chicago. I'm one of your hosts, Stephanie Hendrixson, and I'm joined in the studio today by Pete Zelinski and Julia Hider. We are going to share our overall impressions of the show as well as what we saw what we learned and the key trends we found related to additive manufacturing. That's all coming up on AM Radio.

Julia Hider

The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo, the leading industry event focused on 3D printing for production. Plan to join us October 12 through 14th at the Duke Energy Center in Cincinnati, Ohio. Learn more at AdditiveConference.com.

Stephanie Hendrixson

Welcome to AM Radio. I'm Stephanie Hendrixson. I'm joined today by Pete Zelinski.

Peter Zelinski

Hello.

Stephanie Hendrixson

And Julia Hider.

Julia Hider

Hey Stephanie.

Stephanie Hendrixson

So, we are here today to talk about RAPID + TCT. 2021. Kind of like the first major additive manufacturing trade shows since 2019. But just for a little bit of background like, let's start here like Pete, what is RAPID?

Peter Zelinski

RAPID? Yeah. Trade show has been something, like, 30 years old, maybe a little more, was called RAPID for the longest time, became RAPID + TCT in more recent years. Yeah, it is the biggest trade show in North America devoted to additive manufacturing. And it's a show that is sort of tracked with the development of 3D printing for industry. That name RAPID sort of is a- is a legacy of when 3D printing was a RAPID prototyping technology. The show has become more industrial during the last decade, to the point where it is in additive manufacturing show now focused on industrial applications of 3D printing and in North America. Yeah, it's the biggest trade show addressing that.

Stephanie Hendrixson

So, this was kind of a weird RAPID, like, usually the show is in the spring. This year, it was in September due to everyone pushing events back as a result of the pandemic. It was also co-located with FABTECH, which is a fabricating show. So, like, that was a little bit unusual. And we were all wearing masks — there was a masked mandate. So, anywhere inside of McCormick Place in Chicago, you had to be masked up most of the show.

Peter Zelinski

Yeah, so, so RAPID this year, um, traffic was down, attendance was down, understandably. You know, we're still in an environment where lots of companies have travel mandates and couldn't send somebody if they wanted to. Um, you mentioned co-located with FABTECH — that wasn't a part of the initial vision when it was originally scheduled for the spring, but as it got delayed, that co-location is the opportunity that RAPID found to find some space in the fall schedule. And this thing I just said about kind of the attendance down and maybe limited really to the- to the really serious, the really serious people who are- who are intent on additive with the FABTECH connection actually kind of helped with that.

So, I think of ExOne, an exhibitor at RAPID. They make binder jet machines, and the thing that they were emphasizing is we associate binder jet with production parts with scale production additive, but they're finding usefulness and application and making tooling. And ExOne was showing a mold, an injection molded like they were... It made ice cream scoops, and they were handing them out. The FABTECH people came down, they wander down from the show, and that really drew attention. They noted that, “Oh, you can use this to make tooling.” I mean, that world uses a lot of tooling to stamping dies, for example, and so that element really helped build some bridges.

Stephanie Hendrixson

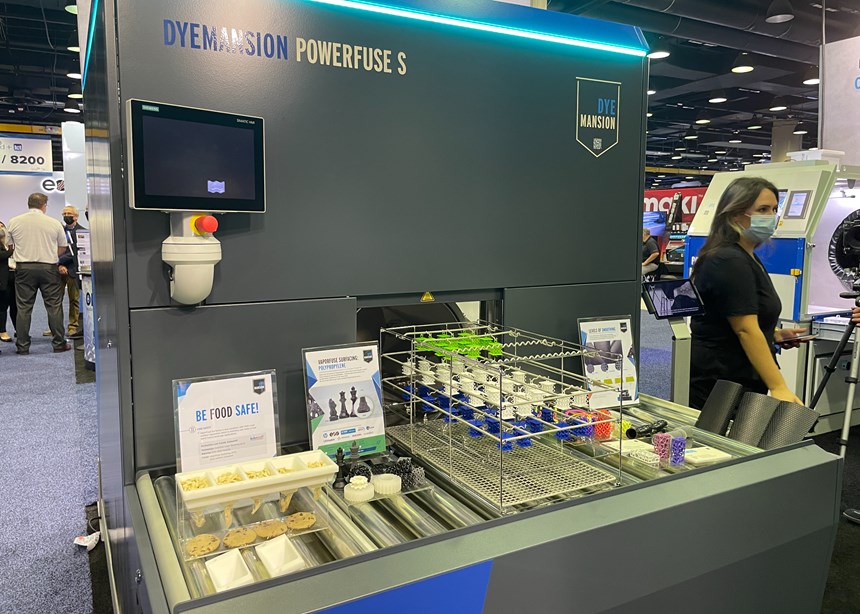

Yeah. Yeah, I mean, you know, as far as the show overall, in the way that it felt, it did feel like attendance was light. It felt like there were fewer people on the show floor. Like, we're all journalists — we spend an entire trade show just running back and forth between booths. And I did feel like I was, you know, ducking and weaving and dodging fewer people in between, in between those appointments. But everyone that was there, everyone that I talked to almost universally, was very happy to be there and was excited to be out and about, to be having these conversations, to be showing off their parts in person. One of the early meetings that I had was with Dimension, which makes automated finishing equipment. And they talked about how difficult it has been for them over the past year to make sales and to explain their technology to people because without holding the unfinished and then the finished part in your hand, it's really difficult to understand what the value is, and what the solution is capable of.

Peter Zelinski

Wow, that's so true. Some of this stuff is just nuanced enough. If you're not in person, if it's not tactical, you don't quite get it.

Stephanie Hendrixson

So, Pete, you and I have been to a number of RAPID variations over the last couple of years. But Julia, this was your very first RAPID, so I'm wondering if you have any, any initial thoughts or reactions?

Julia Hider

Yeah, like you said, this was my first RAPID. This is my first event since I joined Additive Manufacturing, and it's a weird one. So I, I have nothing to base it against. All I know is what I saw at the show. But it was really cool to be able to go to a show and see everything geared towards additive. You know, when you go to, like, a bigger, more general manufacturing industry show like IMTS, additive is relegated to a pavilion or something. And you kind of have to talk about it in more general terms to sell it to the more general manufacturing industry, but at RAPID, because everybody there was already sold on additive, you could get more nuanced and more detailed, and everything was geared towards that, you know, the attendees, the keynotes and the other programming too.

Stephanie Hendrixson

Okay, so some broad overarching impressions and summary of the show. But we do have some more specifics to talk about today. We have about five major themes that we're going to cover in this episode. And I think we should just kind of dive right in. So, the first would be the effect of the pandemic. That was sort of, like, the inescapable conversation topic throughout the show. And I wonder if either of you, you know, have anything to share about that if you've learned anything about how the pandemic has influenced additive.

Peter Zelinski

Like, that was maybe the main, the main thread I found myself exploring over and over — the business impact of the pandemic is spotty. I would say it's been like everything with COVID, the effects are not distributed evenly. Some, some people are hit harder than others, some businesses and additive were hit hard, harder than others. You asked the question about the pandemic, what effect will it have on additive, and a lot of people turn right to the supply chain, like all of the supply chain disruptions we have had, and are still having, and it seems logical to expect 3D printing is going to get to play a role in the answer to that. It's going to lead to different choices of manufacturing processes in the future.

I think about one company conversation, I guess I had on this theme, with EOS. And they sort of talked about reordering of priorities as a result of the pandemic, that there's a roadmap of things they wanted to wanted to do and take care of. But as some commercial opportunities got taken away because of the pandemic, that just allowed other priorities to go up higher on the list and maybe realize more quickly than they would have thought. In the U.S.’ case, they now have what they're calling, they now have what they're calling AM Academy. It's digital training modules that, I think, they've got, they said something like 50 online courses now. And it's a new revenue stream for them, developing additive manufacturing education.

For EOS, sustainability was like that too. Greater emphasis on sustainability is something the customers in general in the additive space push for, and in some cases, it's the part of the reason for embracing additive, particularly for consumer products. But these were more forward-looking things, more farther horizon things that, in some cases, have gotten moved forward more quickly. So, the recyclability of PA12, for example, they cited that they've made some real strides there earlier than they thought they would make them. And, and getting to a 100% recyclable polypropylene is an initiative that, my understanding, that happened because of freed up engineering capacity during the pandemic.

Stephanie Hendrixson

You know, I noticed a lot more recycled materials and things like that on the show floor. I guess I never had a conversation that made the connection between that and the pandemic. That's, that's pretty interesting. But you mentioned, like, shifting priorities. And that reminds me of a conversation that I had with Ken Burns of Forecast 3D.

Forecast is a California-based company; they're sort of like a Multi Jet Fusion power user. They make a lot of parts with that technology. And in 2019, they were acquired by GKN, which is a metal parts producer. And the businesses, they work together, but they're sort of divided, like, along material lines from what I understand. And Forecast was one of the manufacturers that was really heavily involved in making stuff related to the pandemic. Like, they made the official visors, they were printing swabs at one point. But they also got other business as a result of those supply chain disruptions where they were making plastic parts through Multi Jet Fusion that previously would have been injection molding in Asia. And so, they became sort of like this stopgap measure for a number of OEMs and other clients. And that whole experience kind of crystallized for them that, actually, that's not the space they want to play in when you have to do production. That's, that's so rapid you don't have a lot of time to, like, tune the process. You don't get to optimize different steps — you just have to figure out something that works and just go forward with it as fast as you can. And so, kind of coming out of this, this period of time, where they're doing is reorganizing into sort of a product development side of the business, and then more of these, like, vertical product groups that will serve different types of customers. And their objective is to try to take those customers basically from beginning to end, and to get into serial production with additive manufacturing. And so, I think, Forecast 3D, like, maybe eventually, they would have gotten to this point anyway. But as a result of the pandemic, they — it's, it's really kind of crystallized the direction that they want to go.

And that sort of ties into our next trend, like, I want to talk about distributed manufacturing. That, that same conversation with Forecast 3D, is something that they're doing later this year is, they will be opening a Forecast 3D facility in Auburn Hills, Michigan. So, it's an existing GKN facility that already has metal printing capacity, but they're going to be moving some MJF printers and some other things into that, into that area. Part of the reason is because they have some automotive customers, like that's one of their product groups that they'll focus on. They're making things for prototype vehicles as well as full scale production. But they also want to just kind of walk out this idea of distributed manufacturing, like we've been talking about this as a solution to supply chain problems for so long. And, and this will be kind of Forecast’s chance to prove that it works and start making some parts in the Midwest and not doing all the production in California. And assuming this is successful, they'll do the same thing with another GKN and facility in Germany.

Julia Hider

Yeah, distributed manufacturing. Markforged had an example of that running in their booth. The company just released their Eiger fleet software, which is a cloud-based platform that's designed to provide users with centralized control of their operators and printers and parts library, regardless of location. And they were demonstrating this by running a little print farm that was making sample parts. They had, like, six or eight printers in their booth downstairs at RAPID, and they said that they were connected to another print farm that was running in their booth upstairs at FABTECH. And they were running it all via Eiger fleet. So, that was an example that was running at the show.

Peter Zelinski

I didn't get that I saw both of those. I saw all the Markforged printers in the booth at RAPID. I saw them. I saw them — their printers at FABTECH. So, there was all one print farm in McCormick. Yeah, so that's pretty cool. And so, like, I think that would that might mean Markforged is the company that brought the most 3D printers to the show. I think that's really possible. Okay, so let's pause there for a second. We've now started to talk about 3D printers, about the machines. They did have 3D printers at RAPID, so let's dive into that more right after this.

Julia Hider

The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo, the leading industry event focused on 3D printing for production. The conference takes a practical applications-based look at the machines, materials and methodologies being used to create and use tools and components. The event is designed for owners, executives and engineers as well as OEMs involved in durable goods manufacturing. Join the Additive Manufacturing team in Cincinnati, Ohio for two days of in-depth conference sessions, exhibits and networking opportunities with AM experts. Also, on the expo floor, check out the finalist entries in the Cool Parts Showcase, a contest to find the next step. Next of our video series, The Cool Parts Show, be sure to vote on your favorite. The Additive Manufacturing Conference and Expo runs October 12th through 14th. Find out more details and register at AdditiveConference.com.

Peter Zelinski

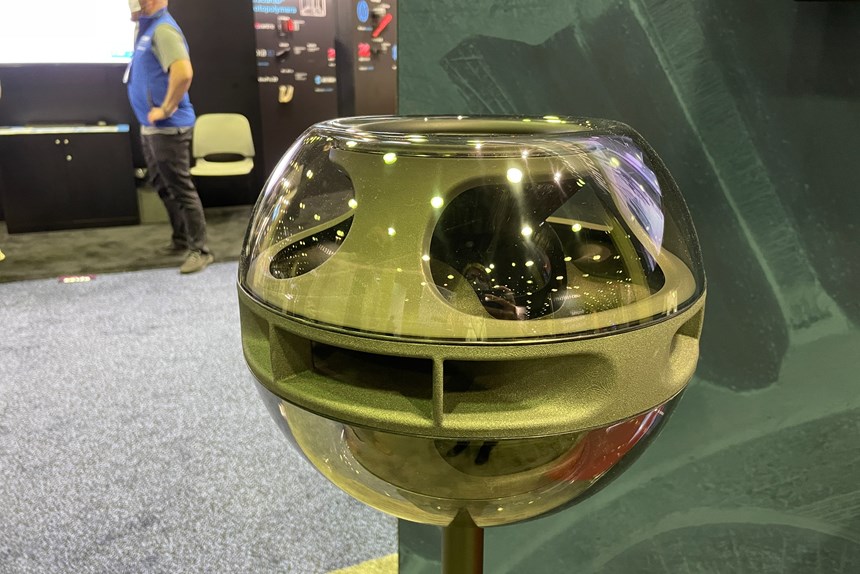

Okay, we're back. So Stephanie, Julia and I are kind of comparing notes after the time we spent at RAPID + TCT. Before the break, we started talking about the machines, the 3D printers. Let's like, let's get into that. Let's nerd out on the machines a little bit. I think a theme I saw at RAPID this year, really simple, but, but big machines move toward bigger build size. I mentioned EOS earlier. So, they had this part on display. It's this, it's this big copper combustion chamber for launch vehicle spacecraft. And EOS has this group that makes custom machines for customers that have special needs in their equipment. And I heard about how a few different customers all asked for roughly the same special request a machine with a tall build envelope side, and that, that combustion chamber was an example of a company with that need. But it's also going to become, or is now, a standard machine. But it all just points to there's a lot of versatility, there's a lot of possibility that comes from having a larger industrial 3D printer. And, like, I think I saw, I think I saw that happening.

You know, it's additive — it's a very dynamic space. And so, there's people changing jobs, people changing employers is, like, a pretty, a pretty normal part of it. And so, I encountered someone who was working for a company different than one, than the one I had previously associated this person with. And, and, and my friend told me, you know, part of the reason for the job change is previously, there just wasn't a good, large envelope option with that, with that previous company. And it limited what it was possible to say to customers coming with that request. And so, just the chance to represent a portfolio that included a range of sizes that reached far there, that was very appealing in that person's case.

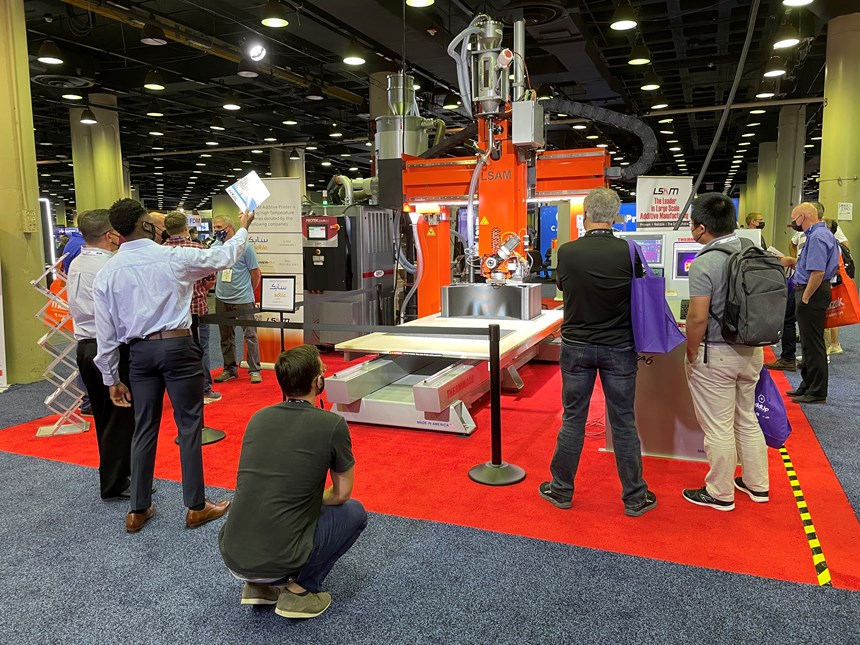

I guess I also like on the show floor, yeah, attendance was light. But there were clusters around interesting things here and there, and Thermwood was there with, like, ironically a machine they probably consider pretty small for them — they make really huge polymer additive machines — but a machine they consider pretty small. It was probably the largest machine that was running on the shop floor, I'm almost certain, on the show floor. I'm almost certain that's true. And, and that a lot of, a lot of crowds. And with people kind of staring intently at that to the extent like you could just kind of see the wheels turning.

Stephanie Hendrixson

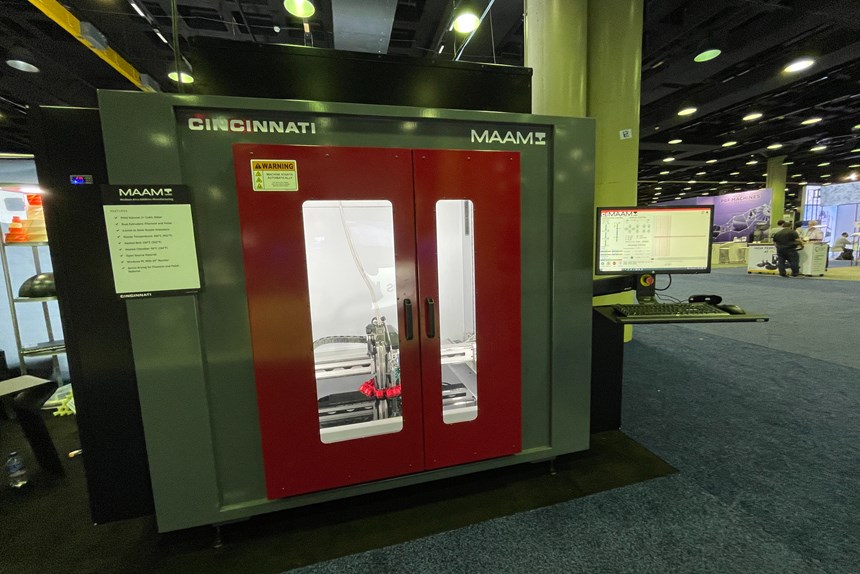

It's interesting that you point to, like, large format 3D printing, I think the trend that I would articulate from RAPID this year was actually something like medium format 3D printing? So, like, Thermwood had its smallest machine. Then Massivit had a large printer there with a build volume, something like four feet by five feet by six feet, which is either enormous or not that big, kind of depending on your perspective. And then Cincinnati Inc., another company, like, sort of similar to Thermwood, in that they know how to build printers that are the size of a room, had their Medium Area Additive Manufacturing machine, the MAAM, on the show floor. And so, this Company that, that is really good at making, like, the Big Area Additive Manufacturing machines, the BAAMs, had to learn some significant lessons to, like, condense all of that down into a smaller printer. But now, they have this printer, the MAAM allows you to print with pellets or filament. So, you have a lot more flexibility in terms of materials. And they see this being used for prototypes for large end use parts. And also for tooling. So, you mentioned the connection with FABTECH and how some of the attendees were sort of going into both exhibit halls and noticing the 3D printed tooling at RAPID, Cincinnati had a couple of great examples of that in their booth for thermoforming, for die stamping and a couple of other cases.

Peter Zelinski

Okay, medium sized, I think what comes right to mind. So I stopped in to see Roboze. And, and their thing is very precise polymer 3D printers, including some that are like not desktop size, but kind of on the smaller side, except they were there with a bigger machine. They were there with a machine that's, like, getting to look, like, sort of like CNC machine tool size to an extent and, and so I guess, Roboze is going up and, and Thermwood and Cincinnati are introducing something that comes back down. So yeah, maybe they do meet him. Maybe there is some just like, just right polymer 3D printer that that is, that is in this middle space.

Julia Hider

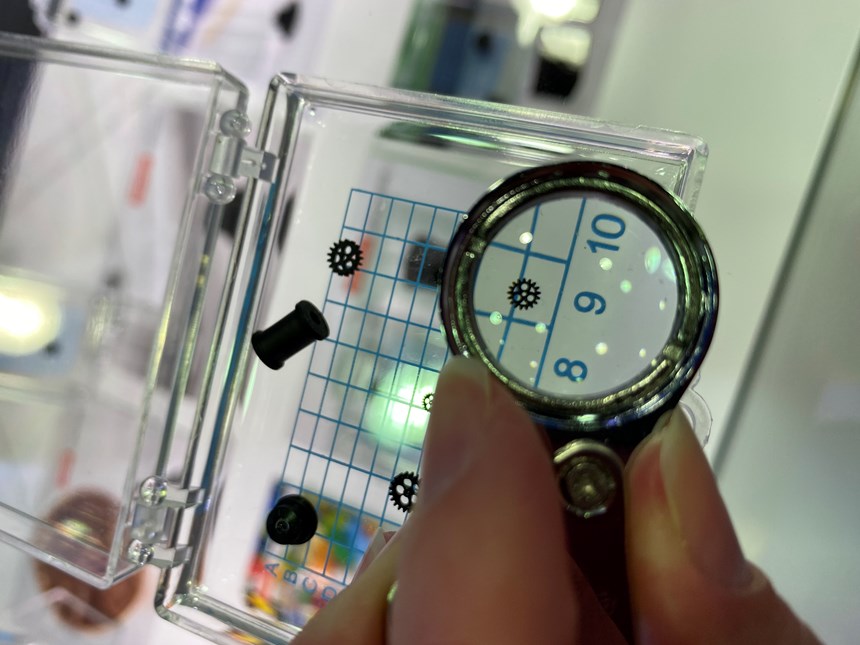

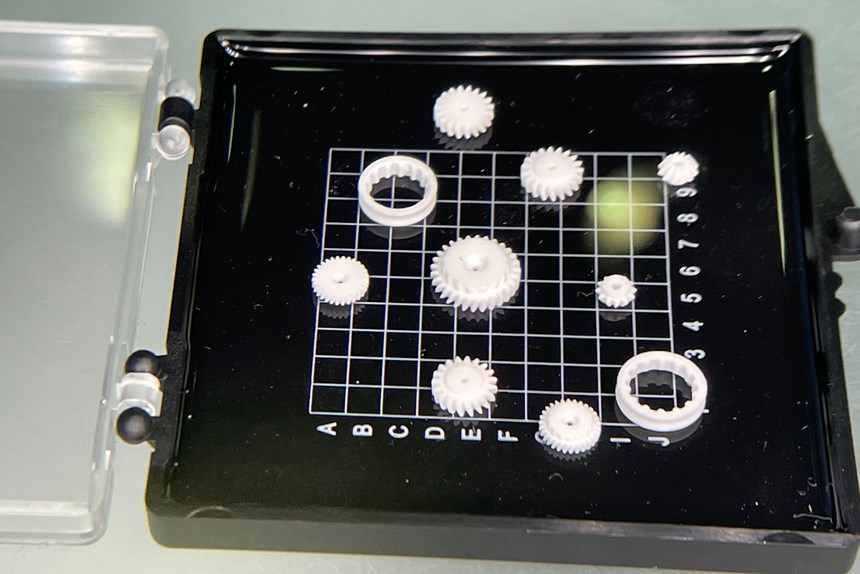

So I agree that I saw this trend of machines getting bigger or more medium size, depending on how you look at it. But I also noticed that micro 3D printing was a trend as well. I visited the Nano Dimension booth, which they focus on 3D printed electronics. And they talked about how 3D printing is enabling all these different advances in electronics, like multi-layer circuit boards, with sensors and other things embedded in them. And they had also recently acquired Nanofabrica, which is another micro 3D printing company that I wrote about earlier this year. So I was able to see that machine and some of the micro 3D prints and medical devices they had mentioned, as well as some of the parts made via their micro injection molds that were printed on the system.

Stephanie Hendrixson

Yeah, so micro 3D printing. Definitely agree. Like, Julia, you and I also visited Boston Micro Fabrication together, BMF, which has a solution for micro 3D printing. They were showing off their new high temperature ceramic materials that they're able to print with. And you and I stood there for, I don't know, five or 10 minutes, just trying to, like, take good photos of those tiny little parts.

Julia Hider

The struggle is real.

Stephanie Hendrixson

Yeah, so we struggled. Eventually, we just gave up and used the magnifying glass there. But you can find all of those photos on our Twitter feeds. And like our attempts at showcasing this.

So, I guess I want to get to our last trend here. And I think the way I’d describe this is something like automation through software. I had conversations throughout the show in which people at different points said something along the lines of, “We need to remove the artisan from the process, we need to reduce the manual steps in the process, we need to make 3D printing like less of this specialized art form where like you need a PhD to stand there and operate the machine because things could go wrong.” And I saw a couple of different examples of software that is sort of targeted at automating these different process steps. So, one example would be DEDSmart or “dead” smart, which is a software introduced by Formalloy at the show. They do directed energy deposition — they develop the machines, the nozzles. And what DEDSmart does is it captures the speeds and feeds things like the laser spot size, the laser power throughout the entire DED build, including anything that the operator might do while the print is happening. And so, basically, they're generating, like, a digital twin of the entire build which you can then play back, like use it to look for problems. If you think there might be, like, some porosity or something, like you can check that through this playback and then use that to target your CT scanning, your destructive testing, like anything like that. So, this is sort of a quality control solution right now. But once you have a process that works for a given part, you can use this to recreate it so that you are consistently making the same part over and over. You no longer need the PhD, standing there, like, adjusting the knobs in real time. You can just rely on the software for this and so, like, this is a step towards closed loop control. It's also, you know, a step towards that, that greater repeatability, greater dependability for the process.

Julia Hider

Yeah, automation via software. I think this is a big focus for 3D Systems as well. I spoke with them about how they recently acquired Oqton. And that company makes what they call a manufacturing operating system. So not only is it connecting the whole additive manufacturing workflow, it has some of these automations built in, like using AI to help automate programming and nesting and planning and scheduling, which is all going to help users scale it to production.

Stephanie Hendrixson

So, maybe just one more example. And Julia, I think you stopped by their booth as well.

Julia Hider

Yeah.

Stephanie Hendrixson

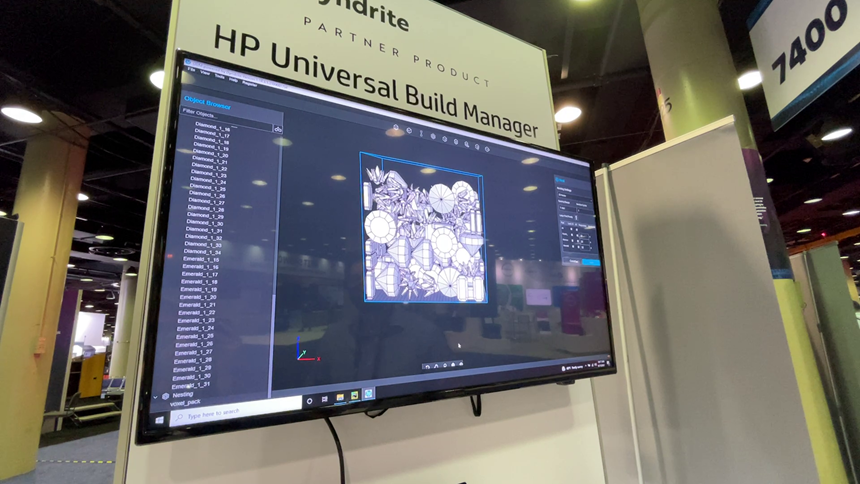

But on the last day of the show, I went to Dyndrite, which is a company that's developing these different APIs to help automate, simplify, democratize essentially 3D printing, and one of the demos that they showed me was this way of automating your build preparation for Multi Jet Fusion, for HP printers. And basically, like, you load your part files into the software, you tell it how many, you know, how many instances of each part you need, you can set different rules about, like, how far away they need to be from each other in the build volume. And then you just click this button, and it just generates the entire, the entire batch of parts in the orientation that they need to be in in their exact location in the build volume. And so, this is a process that might take an engineer, like, an hour or more to place all those parts inside of, of that printer. And this condenses it just to, like, a couple of seconds. So, I thought that was a really interesting case for how software can really automate and help, like, speed up the process of 3D printing,

Peter Zelinski

I actually think this is a great place to stop, a great place to go out on, a great like platform to stand on to look forward. Because the machines themselves, the hardware itself, it’s, I don't want to say simple, but it’s straightforward. And it’s, it has advanced a lot. You know, it’s the machines are it’s a, it’s an energy source moving across a better powder, or it’s DLP machines that have gotten out pretty fast. And, and we’re coming to the point where with the machines, we’re getting new capability by elaborating on what’s already been established, more lasers, for example, and all and that, or more size, more travel. And that’s — all of that is legitimate and important. But the next place to look sort of, the breakthrough capabilities of the future, are going to come from digital capabilities and the ability of software to manipulate these systems control these systems and take them to a different place. And that’s, we should watch for that.

Stephanie Hendrixson

Yeah, I think we'll leave it at that and plan to watch for those developments in the future. If you want to actually see some of the things that we discussed in this episode, check out our slideshow, which is linked in the show notes, or you can find it at additivemanufacturing.media. You can also check out our special episode of The Cool Parts Show where we highlight eight interesting examples that we saw at RAPID that's on YouTube or at TheCoolPartsShow.com. Thanks for listening, make sure to subscribe, and we will be back with a regular episode next week.

Julia Hider

This episode of AM Radio was recorded with help from Austin Grogan and Kate Nicholson. The show was edited by Alex Lytle, Stephanie Hendrixson and Troy Brewer. Our artwork is by Kate Bilberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I'm Julia Hider. Thanks for listening.

Read Next

What Distinguishes Additive Manufacturing?

Is a 3D printer just a machine tool working in reverse? Or is it something else entirely? Stephanie Hendrixson, Peter Zelinski and Julia Hider discuss in this episode of AM Radio.

Read MoreIntroducing AM Radio, a Podcast from Additive Manufacturing Media

Additive Manufacturing Media editors explore 3D printing success stories, AM trends and more on this new podcast. Subscribe now!

Read MoreWhy Do So Many Additive Manufacturers Build Their Own 3D Printers? AM Radio #2A

It's not unusual for companies making parts and products through 3D printing to also develop the printers they use to do so. Stephanie Hendrixson and Julia Hider share examples and discuss why this happens on the latest episode of AM Radio.

Read More

.jpg;width=70;height=70;mode=crop)