Space

Lockheed Martin: Importance of Closed-Loop Control in AM

Process repeatability will enable the satellite maker to apply additive manufacturing to the production of critical parts.

Read More3D Printing for Space Station Freezer Interior

For a freezer to be used in orbit, growing the interior structure in one piece eliminates joining and brackets to maximize the space efficiency of this space-borne appliance.

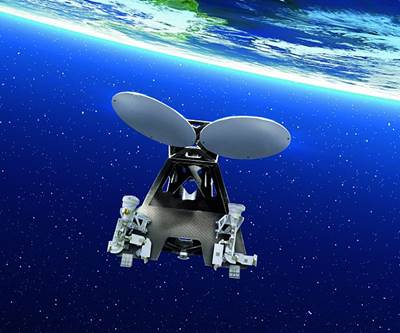

Read MoreSatellite to Use Additive-Manufactured Components Directly Exposed to Space

Support structures are produced through FDM in plastic material as strong as aluminum. Internal complexity is part of the reason for producing the parts through 3D printing.

Read MoreAdditive Manufacturing of Brackets Saves 1 Kilogram per Satellite

Because of complexity, material and quantity, spacecraft and satellite components are good candidates for additive production.

Read MoreVideo: Additive Manufacturing in Extreme Application

NASA’s test of a rocket engine fuel injector made through selective laser melting illustrates an additively produced part’s capacity to perform at high temperature and pressure.

WatchManufacturing in Space

An additive manufacturing process was recently tested in zero-gravity conditions in an effort to develop solutions for manufacturing in outer space. One thing about additive processes—they don’t create loose chips!

Read More