Wayland Additive's NeuBeam PBF Process Creates Parts Free of Residual Stresses

Wayland Additive has been working on the development of an entirely new powder bed fusion (PBF) process for metal AM called NeuBeam.

Share

Read Next

Wayland Additive has been working on the development of an entirely new powder bed fusion (PBF) process for metal AM that minimizes the existing limitations that current users have to work around with laser PBF and traditional eBeam PBF. Wayland Additive developed NeuBeam to provide an entirely new PBF process that is said to offer the best of both laser and eBeam PBF without the compromises to open up greater potential for more industrial applications.

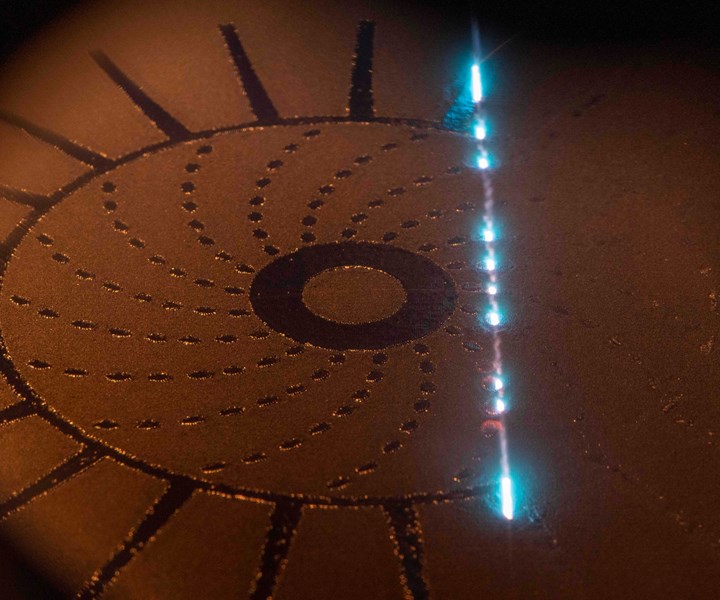

The new NeuBeam process is an eBeam PBF process that effectively neutralizes the charge accumulation generated by the electron beam. The NeuBeam process is said to enable metallurgical requirements to be tailored to application requirements rather to maintain the print process within the narrow bounds permitted by the process. These process capabilities, along with improved ease of process development, opens up the use of a much wider range of metal materials, the company says.

Wayland Additive developed NeuBeam to provide an entirely new PBF process.

Despite a couple of commonalities between EBM and NeuBeam — EBM and NeuBeam are fundamentally different. According to the company, the charging issues that make EBM unstable are not issues with NeuBeam. NeuBeam is a hot part process and not a hot bed process. The high temperatures are only applied to the part not the bed which ensures free-flowing powder post-build and reduced energy consumption, the company says.

The NeuBeam process is said to overcome many of the limitations for manufacturing large complex metal components, namely no residual thermal stresses, no gas cross-flow, and a simplified powder removal process. It also offers significant advantages over other AM technologies with built-in real-time in-process monitoring, allowing for rapid material development or tuning of microstructures by adapting the solidification during manufacture. With NeuBeam the process temperature is not constrained by sintering the powder bed, allowing the process temperature to be optimized to the material microstructure and/or the application, the company says.

Related Content

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.