Stratasys’ Carbon Fiber Material is Stronger, Stiffer ABS

Strong, lightweight, ABS-based material is specifically formulated for applications such as manufacturing tooling, jigs and fixtures.

Share

Read Next

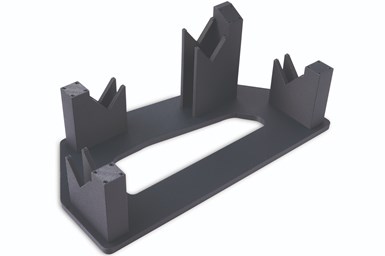

ABS-CF10 offers excellent stiffness for alignment tools like this weldment fixture.

Stratasys’ FDM ABS-CF10 is an ABS-based carbon fiber material for its line of F123 Series 3D printers. It’s the first composite material developed for that platform.

The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, make it a compelling alternative to metal parts, the company says. The material is 15% stronger and more than 50% stiffer than standard ABS, without the weight of metal, and can be printed with a high degree of accuracy. QSR Support water-soluble material makes it possible to 3D print intricate and complex parts without time-consuming manual support removal.

Carbon fiber materials have proven popular on Stratasys’ industrial-scale FDM 3D printers for a variety of end-use applications such as jigs, fixtures and tooling. The company says that FDM ABS-CF10 makes carbon fiber much more accessible to the engineering and manufacturing community for use with its high-performance F170, F270 and F370 3D printers.

Manufacturers are increasingly turning to 3D-printed carbon fiber materials because it’s strong, versatile and lightweight, the company says. Using the FDM ABS-CF10 with Stratasys’ 3D printers means that 3D printing parts that were historically made of metal can lead to a significant cost reduction compared to machining the part out of aluminum, while also reducing overall part weight.

Stratasys’ internal analysis suggests the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between 2019 and 2023, to nearly $600 million, which is double the growth rate of the prior four years. With its FDM ABS-CF10 material, Stratasys is particularly focused on addressing applications in the aerospace, automotive, industrial and recreational manufacturing industries. Parts applications include end effectors used with industrial robots, ergonomic aids such as lift assists and hand tools, and alignment fixtures on assembly lines.

Related Content

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.