Open Mind HyperMill Software Offers Additive Capabilities

RAPID 2020: Open Mind Technologies HyperMill CAM software offers an additive manufacturing capability option to support 3D printing/additive processes.

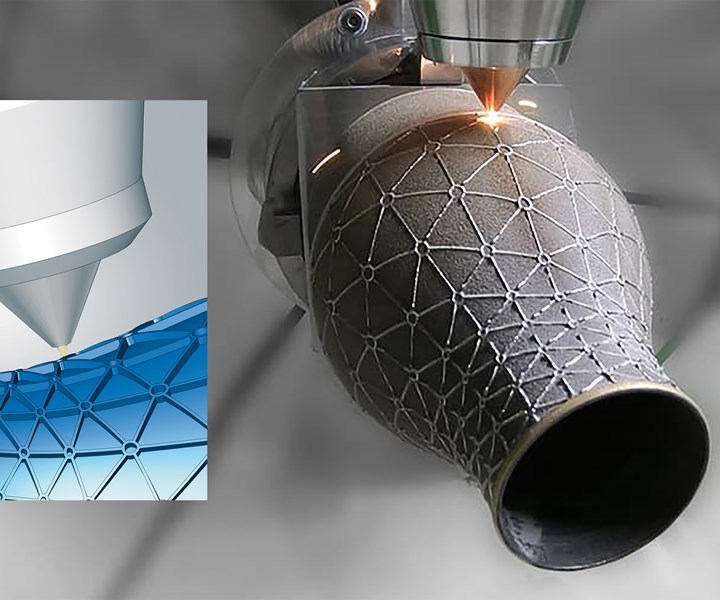

Key additive applications of Open Mind Technologies’ HyperMill Additive Manufacturing software include repair of damaged components, cladding of additional surface skins, or creation of new components from a substrate.

Open Mind Technologies’ HyperMill CAM software supports 3D printing processes and provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

For complex 5-axis simultaneous processing, HyperMill Additive Manufacturing enables an array of flexible options for Directed Energy Deposition (DED) processes and Wire Arc Additive Manufacturing (WAAM). Both laser-based powder nozzle machining heads and WAAM can be controlled using HyperMill Additive Manufacturing for selective material deposition, as well as programmed and automatically simulated for collision avoidance.

HyperMill enables users to perfectly program the cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps guarantee the greatest possible reliability.

Related Content

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

-

7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.