Link3D Software Simplifies Additive Manufacturing Workflows

Technology from Link3D facilitates each step in the 3D printing process for companies.

Share

Read Next

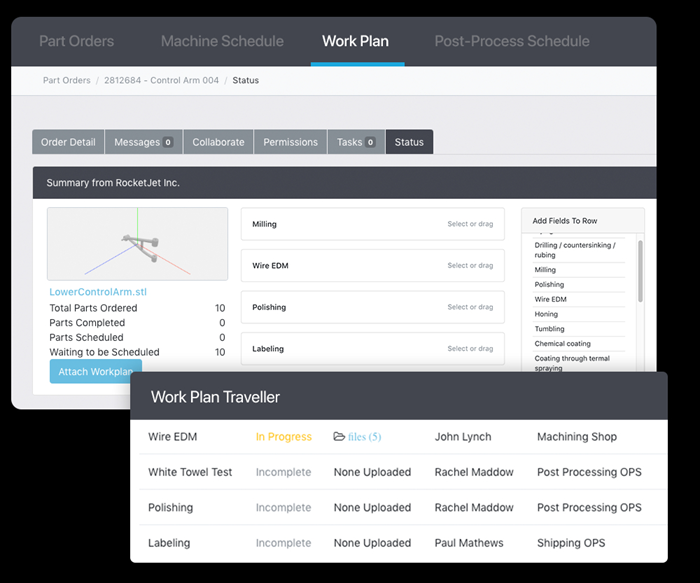

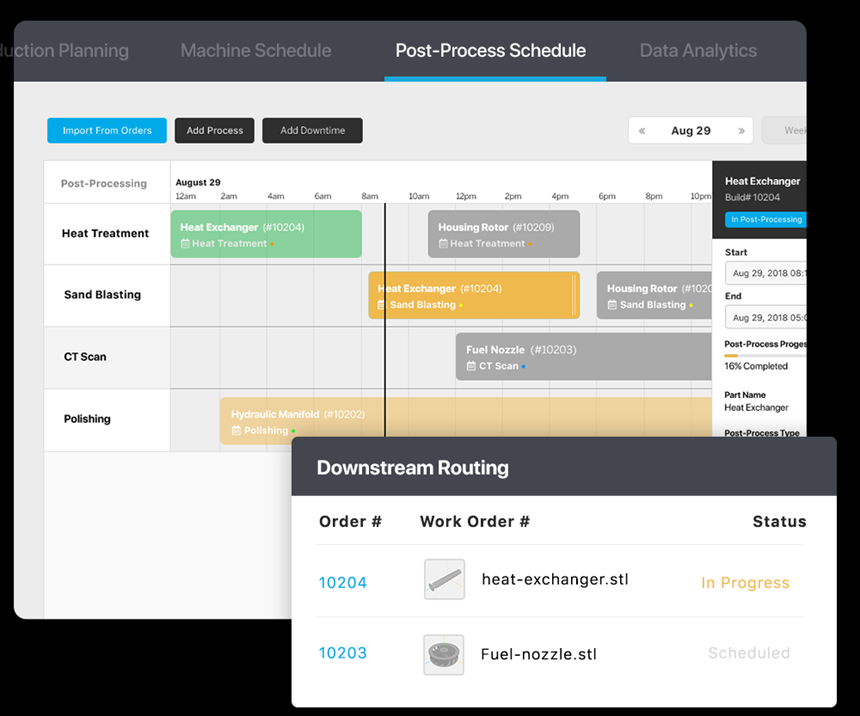

Link3D announces the launch of its postprocessing management software. This product combines downstream manufacturing workflow software with the company’s additive manufacturing execution systems (AMES). The goal of AMES is to help technicians and application engineers plan upstream 3D printing production and downstream manufacturing processes.

Template work plans can be attached to orders for each part of an assembly, and users that are processing parts for post-production are notified of new work in the queue. Detailed postprocessing information will include responsible parties and descriptions and/or checklists for each step in the development of the part, allowing technicians to trace and track activities from beginning to end.

According to Link3D, the workflow software enables greater data connectivity, logging and traceability across postprocessing planning, task assignment, scheduling and more. Post-process management provides a closed-loop yield management system if parts fail during the post-processing stage. Link3D’s production planning software (PPS) supports manufacturing across internal and external postprocessing vendors.

Related Content

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.