Hexcel’s HexPEKK EM Offers Electromagnetic Shielding, Radar Absorption

Composite components are flight-ready after printing, omitting the need for costly and time-consuming secondary processing steps.

HexPEKK EM composite components are flight-ready after printing, omitting the need for costly, time-consuming secondary processing steps.

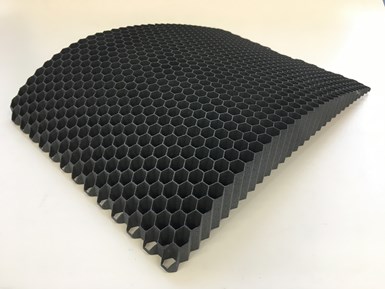

Hexcel’s HexPEKK EM is an electrically conductive, high-performance, PEKK-based thermoplastic carbon fiber composite additive manufacturing (AM) material that integrates advanced electromagnetic (EM) performance within complex 3D-printed components for the commercial aerospace, defense and military sectors.

The company says that HexPEKK EM composite components are flight-ready after printing. Formulated specifically to meet the static electricity management, electromagnetic shielding and radiation absorption requirements of advanced aircraft applications, the PEKK carbon-fiber-blended material delivers unique electrical performance. Manufactured using the aerospace industry-qualified HexAM process, HexPEKK EM components are said to exhibit best-in-class environmental, operational temperature and chemical-resistant performance attainable in the aerospace industry.

By integrating this enhanced EM performance into AM components, HexPEKK EM parts do not require costly and time-consuming secondary processing steps, such as the application of conductive coating for the management of electromagnetic interference or radiation absorption. Target applications for HexPEKK EM cover a broad range of products, including exterior surfaces, leading edges, air inlets, electronic enclosures and cockpit structures for commercial airplanes, military aircraft, helicopters and UAV components.

Related Content

-

Better, More Compact Radio Frequency Devices Through 3D Printing

3D printing technology company Fortify is applying its photopolymer process and material developed with Rogers Corporation to serve the expanding RF market.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.