Henkel, Nexa3D Launch Ultrafast Photopolymer for Rapid Prototyping

The xPRO410 material for general purpose prototyping has a formulation based on Henkel’s Loctite PRO410 polymer and optimized for the Nexa3D’s NXE400 3D printer.

Share

Read Next

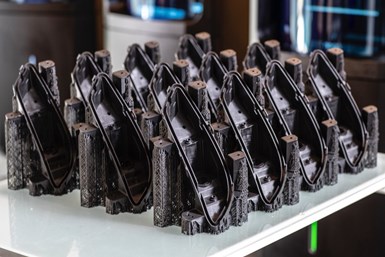

High accuracy parts printed with xPRO410.

Henkel and Nexa3D have collaborated on the launch of xPRO410, an ultrafast general-purpose material for rapid prototyping. Nexa3D, the maker of ultrafast stereolithography production 3D printers, and Henkel, a supplier of high-impact functional additive materials, have partnered to create this new class of photopolymers. According to the companies, it is a rigid photoplastic that prints extremely high-accuracy parts with exceptional surface finish. The formulation is based on Henkel’s Loctite PRO410 polymer and optimized for the Nexa3D’s NXE400 3D printer.

The company says this general-purpose material enables multiple daily design iterations and same day on-demand parts for small and large product enterprises. The rigid material is said to be well-suited for service bureaus seeking to upgrade their services to same day and next day fulfillment. It enables the fast and accurate printing of parts for a wide range of form, fit and function designs, and exceptional appearance prototypes. The xPRO410 can be printed continuously on the NXE400 at speeds of up to 8 L per hour, representing a 20X productivity gain. Parts printed with xPRO410 are said to achieve dimensional accuracy of within 0.2% after postcuring on the Nexa3D xCure system and can withstand temperature exposure of up to 70°C.

Henkel and Nexa3D are working together to apply circular economy principles into their material formulation and printing processes. Through the implementation of end-to-end validated workflows, both companies are measuring and improving to minimize process waste, reduce energy consumption per part and work with customers to reduce their overall carbon footprint.

Related Content

-

Additive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

-

3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

-

When Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.