Formlabs Develops Tough Elastomer Powder for Strong, Functional, Skin-Safe Parts

The TPU 90A powder is the first elastomer material for its Fuse Series 3D printers and which enables durable, skin-safe parts at a low cost for a variety of industries, including health care, consumer goods, manufacturing and engineering.

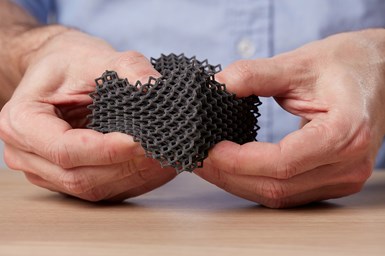

Formlabs’ TPU 90A Powder is a tough elastomer powder and the newest material for its Fuse Series printers. The material enables strong, functional, skin-safe parts with high tear strength and elongation.

The strength and flexibility of TPU 90A powder enables the production of fully functional parts in-house, providing complete design freedom and a seamless workflow on the Fuse Series SLS 3D printing ecosystem. By leveraging this material, engineers and manufacturers can bridge the gap between manufacturing stages, produce fully functional prototypes, manufacturing aids and end-use parts, and take full control of their supply chain. Additionally, TPU 90A Powder is well suited for creating soft-touch components for grippers, padding and cushions.

This high-performance material is also validated for skin contact, making it well suited for medical applications such as prosthetics, orthotics and other patient-specific devices requiring custom designs. TPU 90A Powder’s softness and flexibility ensures optimal comfort and performance, improving outcomes in patient care and streamlining the medical device manufacturing process.

“At Formlabs, we are committed to empowering our customers to truly make anything, from medical parts to wearables,” says Dávid Lakatos, chief product officer at Formlabs. “With the release of TPU 90A Powder, we're proud to offer a material that expands the possibilities for 3D printing across many industries, enabling users to create flexible, skin-safe parts tailored to their specific applications.”

Formlabs’ growing library of SLS materials enables its customers to create parts with a range of properties, including stiffness, softness, ductility and thermal stability. TPU 90A Powder offers flexibility and robustness along with the accuracy and design freedom enabled by the SLS printing process.

Benefits include high tear strength and elongation at break 110-310% for strong and functional TPU parts; low cost per part for low-volume production of 3D printed, flexible parts; and skin safe, making it well suited for printing medical appliances and wearable accessories. It also offers users lower waste and higher efficiency, with a refresh rate of 20%.

- Learn about Formlabs’ Dental LT Comfort Resin which is a flexible, durable material for comfortable long-term occlusal splints, nightguards and bleaching trays. BioMed Durable Resin is approved for human contact, enabling durable biocompatible and impact-resistant medical devices and instruments.

- Read how Formlabs Dental offers solutions for making digital dentistry easier. Formlabs’ dental offerings enable dental labs and practices to reduce costs and increase efficiency, while delivering industry-leading print quality.

Related Content

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

-

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.