Farsoon Flight 403P Dual-Laser Platform Offers High-Temp Plastic LPBF

Formnext 2023: Farsoon’s 403P Series offers a versatile, powerful platform for plastic laser sintering that can achieve two full industrial-scale builds (cylinder size 400 × 400 × 540 mm) within 24 hours.

Share

Read Next

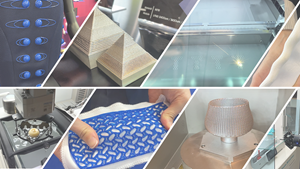

Farsoon’s Flight 403P Dual-Laser Platform series is a high-temperature plastic laser powder bed fusion (LPBF) platform. As one of the first machine manufacturers to develop production-targeted LPBF systems using industrial fiber lasers, Farsoon introduced the development of the dual-laser configuration of Flight (Fiber laser) technology and its application on the 403P platform.

Boosting significantly 3-4 times production yield compared to a single CO2 laser SLS machine, the dual laser Flight 403P system can achieve two full industrial-scale builds (cylinder size 400 × 400 × 540 mm) within 24 hours. The advanced features include removable cartridges and an external cooling station which can further improve the machine uptime and create higher throughput with the same footprint.

With robust laser power, improved energy distribution to the material and smaller laser spot size, Flight Technology is able to achieve the full sintering of powder in a significant short amount of time. It was developed to address the requirements of industrial-scale series production using LPBF technology, increasing the manufacturing turnover rate and accelerating the product-to-market cycles. The dual-laser configuration for Flight technology takes advantage of two powerful 300-W fiber lasers and two dynamic optical systems, creating two ultrafine laser spots with fast scanning speed of up to 20 m/sec (66 ft/sec) for each.

Equipped with powerful fiber lasers in place of standard CO2 lasers, the Flight 403P-2 Series is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system, Flight Technology also provides improved laser longevity which is key when considering ROI for manufacturing applications.

Like all Farsoon systems, the Flight 403P-2 Series is offered with fully open machine parameters and unlocked material choices. With its increased power and energy absorption characteristics, Flight Technology is capable of accessing a much different range of processable materials and operational flexibility as compared to standard laser sintering systems, which enables increased freedom for future AM material and application development. Customers can freely choose materials for their application according to the specific needs of end-users. Also, Farsoon works with a fleet of global chemistry providers in validation of their high-performance, specialty engineering materials for fiber laser technology.

To further increase the manufacturing turnover rate, the dual-laser configuration for Flight technology takes advantage of two powerful 300-W fiber lasers and two dynamic optical systems, creating two ultrafine laser spots with fast scanning speed. The new dual-laser configuration can offer significantly 50-90% higher production volume rate compared to the single-laser configuration of Flight Technology, and 3 to 4 times production yield compared to a single CO2 laser machine.

The optimal performance of the Flight 403P-2 Series — combining extreme sintering speed and high feature resolution — can open up many potential markets and applications for true series production, such as electronic components, robotics, specialized tools and models, battery units, filter modules as well as many consumer products.

- Learn about Farsoon’s LPBF Systems for large-scale metal additive manufacturing. The FS621M Pro-4, FS621M Pro-6 and FS621M-U-4 systems are said to offer huge potential in aerospace applications by lowering operational cost and enabling true industrial-scale series manufacturing.

- Here’s an even larger Farsoon printer. Read about the Farsoon FS1521M which has 16 lasers for large-format metal additive manufacturing. This metal 3D printing platform series offers advanced multilaser scanning strategies with optional modes for efficiency, quality or balanced performance for different manufacturing needs.

Related Content

Finland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreSemiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More