EOS Introduces NickelAlloy IN939 for Turbine, Energy Applications

Material offers great tensile properties, validation, reliability and crack resistance, which opens industrial 3D printing options for turbines and other energy industry applications.

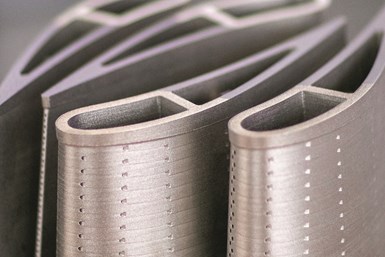

EOS NickelAlloy IN939 opens is well suited for additive manufacturing of industrial gas turbines and other energy industry applications.

EOS has added a new nickel alloy material to its portfolio of metal powders available for use in powder bed additive manufacturing (AM). EOS NickelAlloy IN939 is a nickel-chromium alloy which provides a good balance of strength in high-temperature settings, resistance to corrosion and oxidation, fatigue performance and creep strength at temperatures up to 850°C (1,560°F).

The material offers greater tensile properties, validation, reliability and crack-resistance than similar materials currently on the market, the company says. Parts produced using EOS NickelAlloy IN939 can also be hardened after being manufactured by applying precipitation-hardening heat treatments.

For processing on the EOS M 290 metal AM platform, these qualities make EOS NickelAlloy IN939 well suited for use in creating industrial gas turbines (vanes, blades, heatshields), as well as microturbines, turbochargers, power industry parts and other energy industry applications exposed to high temperatures and extreme elements.

Related Content

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.