BigRep Unveils Large-Format 3D Printer for Industrial Applications

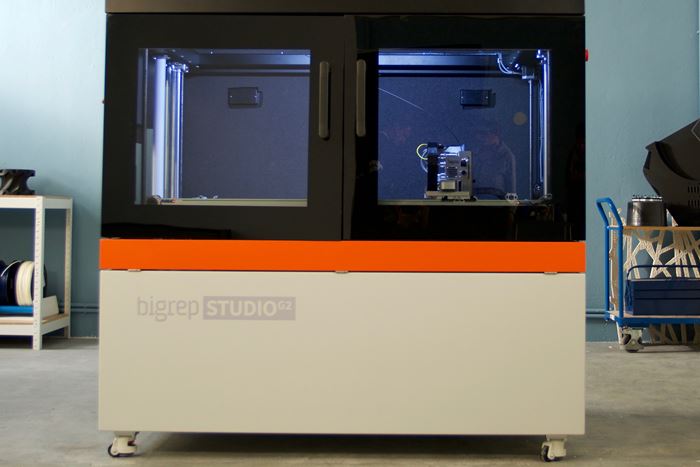

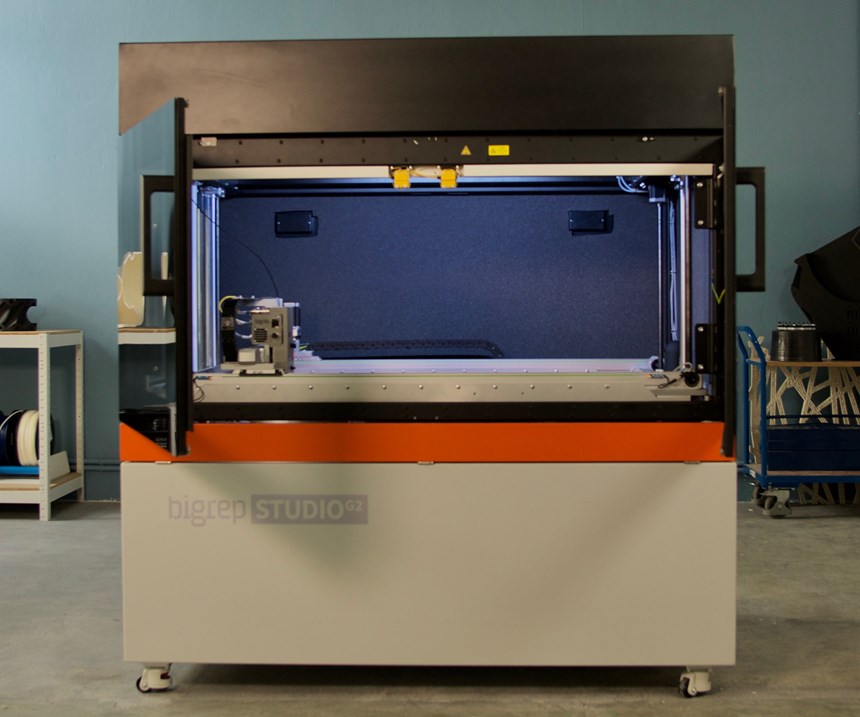

BigRep has unveiled its Studio G2 printer, designed to print engineering-grade materials and large-format objects developed for industrial applications.

BigRep‘s Studio G2 printer is designed to print engineering-grade materials and large-format objects developed for industrial applications.

According to the company, the Studio G2 printer offers optimal speed and resolution in large-format additive manufacturing (AM). The printer includes a fully enclosed and insulated build envelope of 500 × 1,000 × 500 mm, a fast-heating print bed reaching 100°C and a temperature-controlled filament chamber.

With its dual extruder equipped with two 0.6 mm ruby nozzles, the printer is said to be capable of producing detailed results with abrasive engineering-grade materials, such as PA6/66, at layer heights as low as 0.1 mm. Future materials to be released will include other engineering-grade materials like acrylonitrile styrene acrylate (ASA) and composite materials with carbon/glass fiber enhancement, the company says.

The Studio G2 is equipped with BigRep Blade slicer software, which provides accurate printing time and material use calculations to optimize productivity. The Studio G2 is designed to fit virtually any workspace, providing ease of use and accessibility.

Related Content

-

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.