Authentise Platform for Organizing, Sharing Digital Designs

Software platform helps users develop additive manufacturing projects and securely share those designs with production facilities.

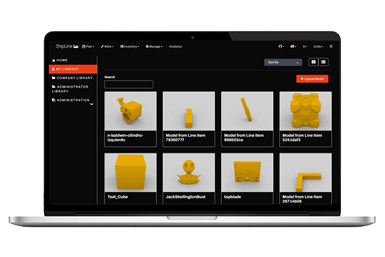

OEMs can use the platform to manage the design and engineering process, bringing multiple design, R&D and testing stakeholders together. Photo Credit: Authentise

Authentise, a provider of data-driven manufacturing and workflow tools, has created a Digital Design Warehouse platform to unite and share additive manufacturing (AM) initiatives and spare part catalogs. The system is said to simplify how digital designs are shared.

The company says the Digital Design Warehouse will help organizations create more cohesive AM initiatives by bringing insights from disparate silos into full view across all teams. The platform enables everyone to create their own personal library by uploading any 2D and 3D file type with fully configurable additional parameters. Those designs can be further analyzed using plugins from third parties such as Zverse (which enables the conversion from 2D to 3D) and Castor (which assesses the project’s suitability for AM).

Sharing is at the heart of the platform. Access is tightly controlled with granular permissions, enabling users to share projects with internal and external stakeholders, such as suppliers or customers. The platform provides a space for users to engage in conversations, edit (where permitted) and view or access designs.

A particular use case for the platform is spare parts. OEMs are able to use the platform to first manage the design and engineering process, bringing multiple design, R&D and testing stakeholders together. Once complete, the design can be shared securely with potential clients via a fully custom-branded catalog. The inclusion of an “Order Now” button enables the design to be sent directly to a production center of choice.

Related Content

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

-

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.