3D Systems Helps TE Connectivity to Additively Manufacture Electrical Connectors

The foundation of the solution is a newly developed photopolymer 3D Systems engineered specifically to meet TE Connectivity’s requirements.

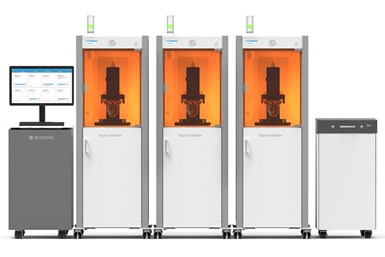

3D Systems collaborated with TE Connectivity to jointly develop an additive manufacturing (AM) solution to produce electrical connectors meeting stringent UL regulatory requirements. The solution comprising 3D Systems’ Figure 4 Modular, Figure 4 material, 3D Sprint software and services was designed to meet TE Connectivity’s unique requirements for material performance and high tolerance, reliable printing.

The foundation of the solution is a newly developed photopolymer which 3D Systems engineered specifically to meet TE Connectivity’s requirements. In addition to a world-class flammability rating at 0.4mm thickness, it is the first known printable photopolymer to complete a UL 1-recognized long-term thermal aging (RTI) study.

This material combined with an optimized print process enables the necessary reliability and accuracy required for TE Connectivity’s products. Using 3D Systems’ Figure 4 technology, the combination of new material properties, speed and accuracy enables the production of rugged industrial products for the first time, targeted at appliances, cellular and data center applications.

AM gives TE Connectivity freedom of design to create complex geometries that would be difficult to create using injection molding. It increases flexibility for low-volume, quick-turn production runs and tooling avoidance, enabling TE to quickly demonstrate its capabilities and its customers to more efficiently meet demand.

The novel workflow enables production of end-use parts in weeks versus months without tooling investment, while the unique photopolymer offers full UL recognition capable of meeting stringent connector application needs. It is the first known 3D photopolymer to complete long-term thermal aging for electrical and mechanical relative thermal index (RTI) certification.

3D Systems’ Application Innovation Group (AIG) collaborated with TE Connectivity’s team to develop a full production workflow from design to a finished connector. The program included the development and UL certification of a new Figure 4 material. UL regulatory approval has been obtained, including UL94 V0 flame rating at 0.4 mm, Glow Wire Ignition (GWI) of 800°C, Comparative Tracking Index (CTI) of 600 V (equivalent to a PLC of 0), and Relative Temperature Index (RTI) for long-term electrical and mechanical use of 150C and 130C, respectively.

“As 3D printing technology evolves, we’re seeing more opportunities for using it to manufacture products for customers who need a low volume of parts in a short time frame,” says Philip Gilchrist, vice president and segment chief technology officer for Communications Solutions at TE Connectivity. “Our work with 3D Systems enables us to provide our customers with functional parts in just weeks instead of months.”

3D Systems says customer-centric innovation is at the core of everything it does. “The collaboration with TE Connectivity provided the understanding and requirements of the unique application being addressed and enabled the development of the solution,” says Reji Puthenveetil, executive vice president, industrial solutions, 3D Systems. “Our materials scientists and print process experts worked very closely with the TE team to formulate a material that, when used in conjunction with our Figure 4 technology, delivered on the high quality, high-reliability standards their customers have come to expect. This is yet another example of how 3D Systems is partnering with industry leaders to accelerate innovation and build competitive advantage through additive manufacturing solutions.”

- Check out this article about 10 Important Developments in Additive Manufacturing Seen at Formnext 2022, including 3D Systems’ redesign for the frame and structure of its machines. One big change: The mechanics of the machine have been moved to the side, so the back of the machine can be opened for robot access.

- In this product post, we talk about two offerings from 3D Systems that are production-grade materials designed to address a breadth of industrial applications.

- In this article about 3D Systems partnering with Ems-Griltech, we learn how the companies are working to advance materials innovation by producing DuraForm PAx Natural, a material available for all selective laser sintering platforms.

Related Content

Nikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Read MoreEndeavor 3D Earns International Traffic in Arms Registration

Endeavor 3D strengthens its technology capabilities and operational systems to better support the U.S. defense industrial base as well as energy and supply chain manufacturing services.

Read MoreBPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.

Read MoreBaker Hughes Successfully Implements Oqton Manufacturing OS System to Optimize Additive-Driven Manufacturing Workflow

3D Systems say this successful implementation demonstrates its Oqton Manufacturing OS’ ability to accelerate the design and production of additively manufactured parts across the entire manufacturing workflow to increase efficiency and facilitate regulatory compliance.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More