Roboze Initiating Circular Economy Program for 3D Printed Parts

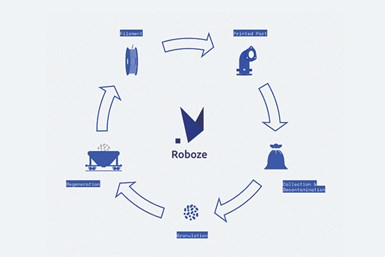

The manufacturer is launching a new project for the recovery of waste material and 3D printed parts to be reintroduced on the market for the benefit of end-users and especially the environment.

The aim of the program is to reduce manufacturing’s environmental impact.

Roboze is initiating a circular economy program beginning in January 2022 that will enable its customers to return waste material and 3D printed parts to Roboze at the end of their life cycle so the company can produce new material from the materials for “circular” 3D printing. This model is designed to enable Roboze customers to receive a “circular” material at a much lower price than the original and help safeguard the environment.

The aim of the program is to reduce manufacturing’s environmental impact. Roboze says that challenge is an opportunity that can drive the intent and responsibility of production models and processes which are more energy efficient and lower overall emissions. According to the company, this is causing a shift toward a new paradigm where innovation and new technologies are born with the ultimate aim of optimizing the consumption of materials and energy.

Roboze provides 3D printing technology for super polymers and composite, working to bring production back to the point of use. Its vision and execution of decentralized distribution of production in favor of microfactories around the world includes its Roboze 3D Parts Network.

It’s looking to overturn the delocalized production model, which sees large standardized production in a single point and shipped all over the world. Instead, the company is focused on a new production paradigm, which it calls Roboze Distributed Manufacturing. This model involves specialized 3D printing centers with Roboze systems distributed all over the world, which produce parts where and when they are needed, thus reducing not only costs and times for end-users but also transport and excess inventory in the warehouse.

“We are working to refine the management of the entire supply chain,” says Alessio Lorusso, Roboze founder and CEO. “3D printing technology can be one of the solutions to combat CO2 emissions, reducing transport and producing just in time and on-demand.”

Related Content

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.