NASA Tests Bimetallic 3D-Printed Rocket Engine Prototype Part

The 3D-printed rocket engine igniter can be made faster, cheaper and more reliably than the traditional brazed part.

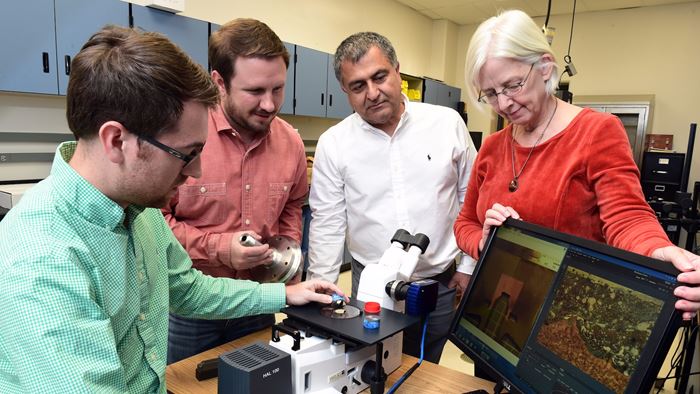

Engineers at NASA's Marshall Space Flight tested NASA's first 3D-printed rocket engine prototype part made of two different metal alloys. NASA has been making and evaluating 3D-printed parts made of one metal, but 3D printing with more than one metal is more difficult.

According to Marshall’s director of the engineering directorate Preston Jones, the process could reduce future rocket engine costs by up to a third and manufacturing time by 50 percent.

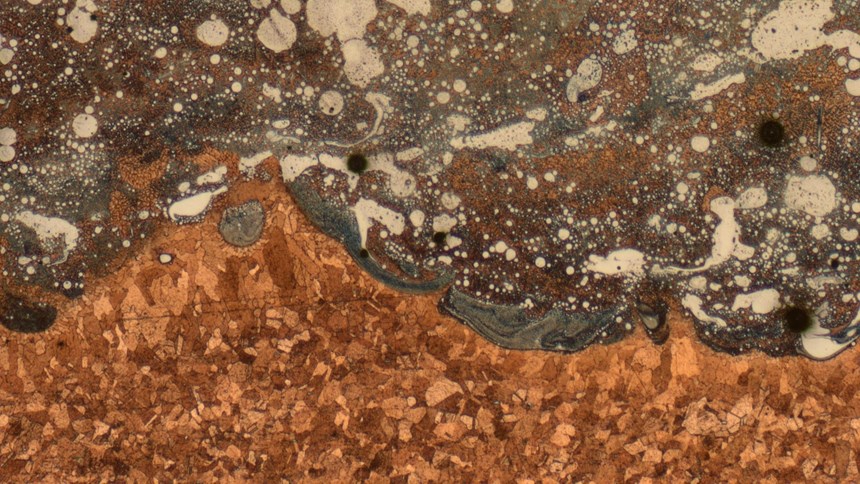

Engineers low-pressure hot-fire tested the prototype more than 30 times to demonstrate its functionality. The prototype, built by a commercial vendor, was then cut up by University of Alabama in Huntsville researchers who examined images of the bimetallic interface through a microscope. The results showed the two metals had inter-diffused, helping create a strong bond.

Rocket engine igniters are used to initiate an engine’s start sequence. They are traditionally built using a process called brazing, which joins two types of metals by melting a filler metal into a joint to create a bimetallic component. The brazing process requires a significant amount of manual labor, leading to high costs and long manufacturing time.

In addition to decreasing cost and manufacturing time, building bimetallic parts in a single machine decreases risk by increasing reliability. Because the bond between the two materials is generated internally, hard transitions that could cause the component to crack under the forces and temperature gradient of space travel are eliminated.

A copper alloy and Inconel were joined together using a hybrid process called automated blown powder laser deposition. Traditionally made of four parts that are brazed and welded together, the prototype was created during a single build process using a DMG MORI hybrid machine. While the igniter is only 10 inches tall and 7 inches at its widest diameter, this new technology enables larger parts and machining of the interior of parts during manufacturing.

Related Content

-

3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

-

Foundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.