Lincoln Electric Helps Get Chevron Refinery Back Online

Lincoln Electric worked with Chevron to accelerate refinery maintenance using Lincoln Electric’s 3D metal printing solution.

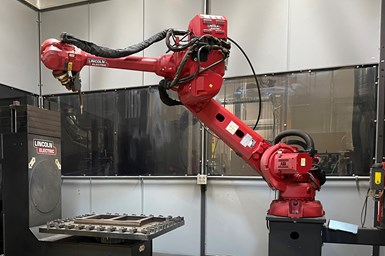

Example of a Lincoln Electric Additive Solutions robot, which offers considerable freedom over an enclosed machine when it comes to reaching around the work space to deposit material at different angles. Photo Credit: Lincoln Electric Additive Solutions.

Lincoln Electric - Additive Solutions utilized its large-scale, metal 3D printing solution to deliver just-in-time parts to Chevron USA to help bring a refinery back online according to schedule. During a recent routine maintenance shutdown, extended lead times and supply chain delays on traditionally manufactured parts challenged Chevron’s planned restart schedule. Chevron’s Additive Engineering team worked with Lincoln Electric to get back on schedule using additive manufacturing (AM) to print critical replacement parts that would meet production and quality standards.

“Our planned maintenance schedule was in jeopardy due to current supply chain issues,” says Robert Rettew, Chevron materials technology engineer. “We realized this supply crunch could impact operations and our bottom line. We worked with Lincoln Electric to explore how parts could be created faster so we could resume operations as planned.”

The two teams worked together, along with industry experts from Stress Engineering Services, to print eight nickel alloy replacement parts that averaged approximately 3 ft. (0.9 m) in length and over 500 lbs (226 kg), each in a total of just 30 days.

“We are pleased to work with Chevron and showcase the value of just-in-time production using additive manufacturing, and its ability to prevent facility downtime,” says Christopher L. Mapes, Lincoln Electric chairman and CEO. “Metal 3D printing for large-sized metal parts, molds, tooling and prototypes is a game-changing solution for various end markets, including industrial manufacturing, energy and aerospace. When speed-to-market, design flexibility and reduced costs take priority, our printing technology provides the ultimate answer.”

With a large, wire metal 3D printing factory, Lincoln Electric’s AM solution for high-mix, low-volume applications is capable of printing metal-based parts up to 7 ft. (2.1 m) in length and weighing in excess of 5,000 lbs (2,265 kg). The company says this innovative technology significantly reduces manufacturing lead times, shortens supply chains and enables design enhancements that exceed traditional fabrication capabilities. Based in Cleveland, Ohio, Lincoln Electric’s metal 3D printing solution utilizes its own SculptPrint software, robotic cells and welding wire to control quality and ensure a reliable supply chain.

Related Content

-

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.