Farsoon, Fabulous Bolster Collaboration for 3D Printed Plastic Food Contact Parts

Partnership focuses on Bluecare material specific for the food industry and Active material dedicated mainly to the water industry.

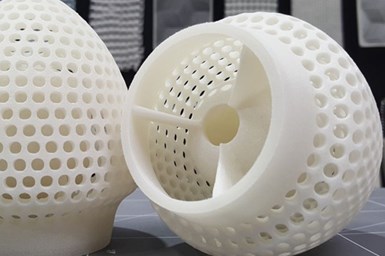

Ricoh 3D printing is using Active material for manufacturing water pump strainers.

Farsoon, a Chinese 3D printer manufacturer, has strengthened its partnership with Fabulous, a French company that specializes in powder materials for powder bed systems. The two companies are collaborating to develop innovative materials with high certifications and properties for 3D printed plastic parts in food and drinking water applications.

To date, all Fabulous’ materials have been successfully tested on Farsoon printers with early adopters’ service bureaus continuously using them. The collaboration focuses on helping end-users with new materials specific to industrial applications, such as Bluecare material specific for the food industry and Active material dedicated mainly to the water industry.

Bluecare is a PA11- bio-sourced powder recognizable for its blue color and which has been certified for Food Contact Application in the EU. IDPrint, a 3D printing service based in France, is using Bluecare powder to design 30-cm wide modular food conveyor belts. According to the company, the material is well suited for the additive manufacturing of parts for food conveyors, as it negates the need for a mold formation which would be too costly for the number of parts to be made.

Active is a material specific to the water industry. It has been ACS certified for potable water applications and plastic parts in contact with drinkable water, such as water pumps, hydraulic systems, data sensors and all permanent water-immersed parts. The North American equivalent standard is NSF-ANSI 61 certification. Due to Active’s composite formulation, it has high standards properties (especially High-T° and low-T° resistances). Ricoh 3D printing service is using Active material for manufacturing water pump strainers.

Related Content

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

-

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.