Farsoon, Covestro Strengthen Cooperation in Engineering Powders

Collaboration entails successful use of Covestro PBT and TPU powders on Farsoon plastic laser sintering machines.

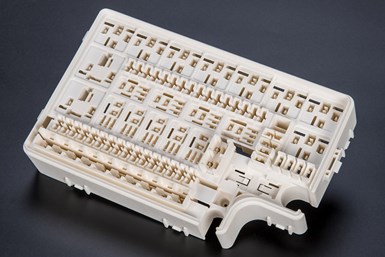

Fuse box made of polybutylene terephthalate from Covestro, produced by laser sintering on a Farsoon machine. Photo Credit: Covestro

Materials manufacturer Covestro is operating Farsoon laser sintering systems in its German and Dutch (legacy-DSM) additive manufacturing (AM) facilities for testing the processing and printing of new materials such as thermoplastic polyurethane (TPU), polypropylene (PP) and polybutylene terephthalate (PBT).

The company says downstream customers have validated the parts for end-use applications in automotive, electrical and consumer industries. Based on customer feedback and success, the two companies are strengthening their collaboration to foster series production of 3D printing.

Both Farsoon and Covestro say they are committed to an open systems philosophy, so customers are free to choose materials for their 3D printing systems that suit their end-use applications. In this collaboration, Covestro is contributing its expertise in polymer-based 3D printing materials, while Farsoon adds its expertise for powder-based laser sintering machines.

Covestro has already successfully launched TPU and PBT polymer powders developed on Farsoon 252P series machines. The development of additional powders and the upscaling to larger series applications is part of the strengthened collaboration.

Covestro, Farsoon and Seifert Logistics Group (SLG) in Ulm, Germany, jointly developed TPU parts for footwear with Seifert fabricating TPU parts on a Farsoon SS403P at high productivity levels. In addition, Covestro, Farsoon and a partner from the automotive industry collaborated to develop end-use parts for interior car applications using legacy-DSM PBT powder Arnite T AM1210 (P).

“We are very pleased to extend the opportunities to the additive manufacturing market by proactively supporting new applications with new polymer powders,” says Dr. Dirk Simon, managing director of Farsoon Europe. “Farsoon SLS machines are very compatible with Covestro’s polymer powders, which offer a very interesting property profile to form an important foundation for our customers’ market success.”

Related Content

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.