Desktop Metal Ships First Additive Manufacturing Production System to Stanley Black & Decker

The P-50 is designed to mass produce high-performance metal parts with the repeatability and cost required to compete with conventional manufacturing.

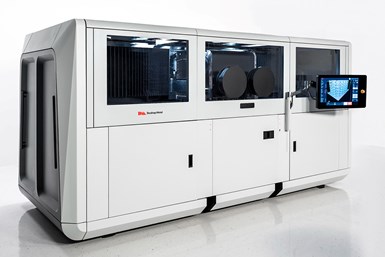

Desktop Metal has shipped its first Production System P-50 printer to Stanley Black & Decker. Photo Credit: Desktop Metal

Desktop Metal has shipped its first Production System P-50 printer to Stanley Black & Decker, marking the commercialization of the company’s flagship additive manufacturing (AM) technology for mass production of end-use, metal parts. Stanley Black & Decker operates one of the world’s largest tools and storage business, including such brands as Dewalt, Black+Decker and Craftsman.

The P-50 is the product of nearly $100 million in investment and a four-year development program overseen by Desktop Metal engineers and materials scientists. It is designed to mass produce high-performance metal parts with the repeatability and cost required to compete with conventional manufacturing.

The company says this printer is the fastest way to 3D print metal parts at-scale and it was created by the inventors of binder jetting and single-pass inkjet technology. The printer is powered by Desktop Metal’s single pass jetting technology. It is designed to achieve speeds up to 100 times those of legacy powder bed fusion AM technologies and enable production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques. The platform supports a materials library which includes 10 qualified metal alloys — from commercially pure copper to stainless steels such as 17-4PH — with additional metal alloys in active development.

Related Content

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

-

Video: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

-

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.